Dynamic balance processing system

A processing system and dynamic balancing technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as unbalanced rotation, achieve the effects of ensuring processing accuracy, reducing mechanical failures, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

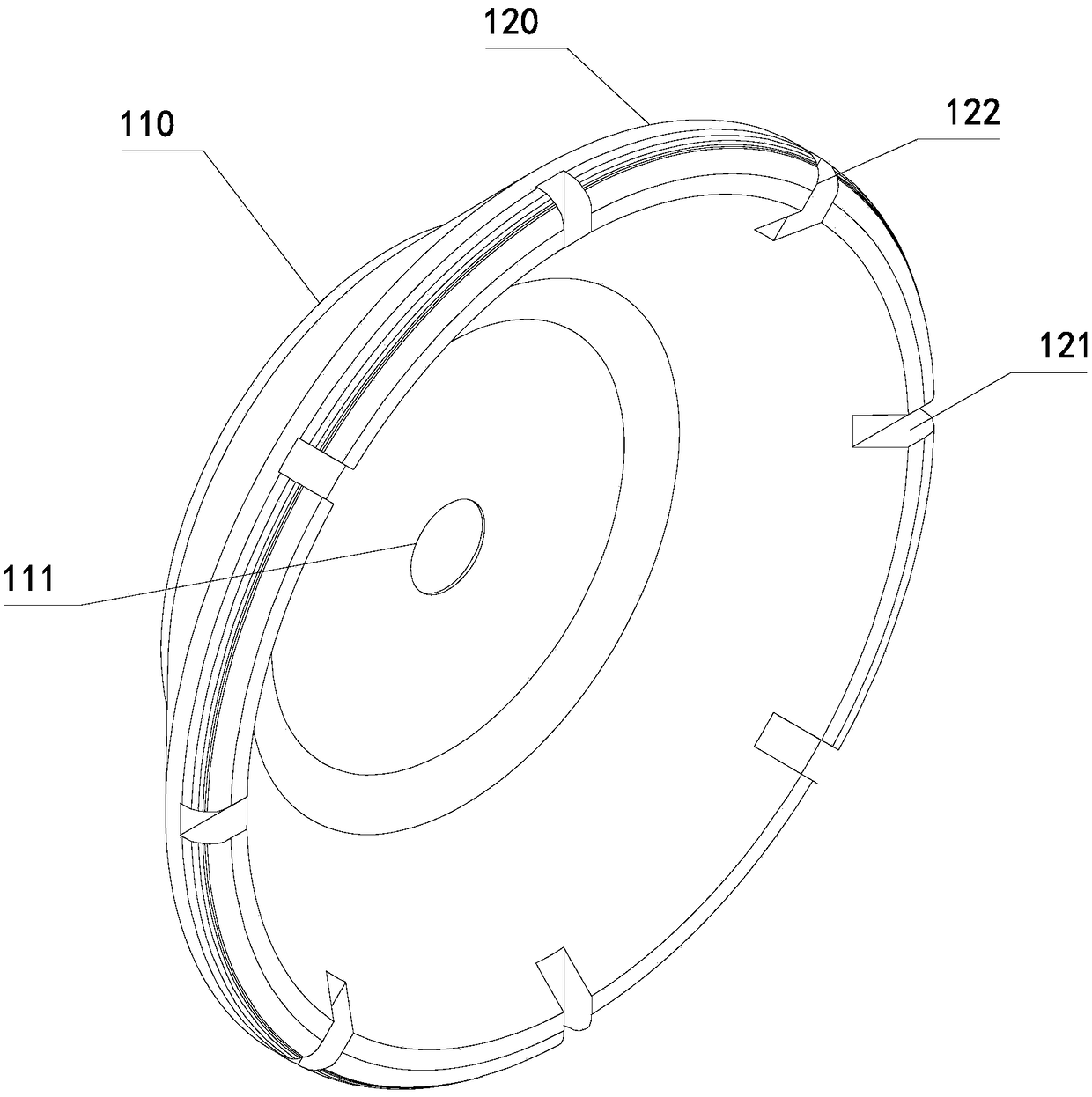

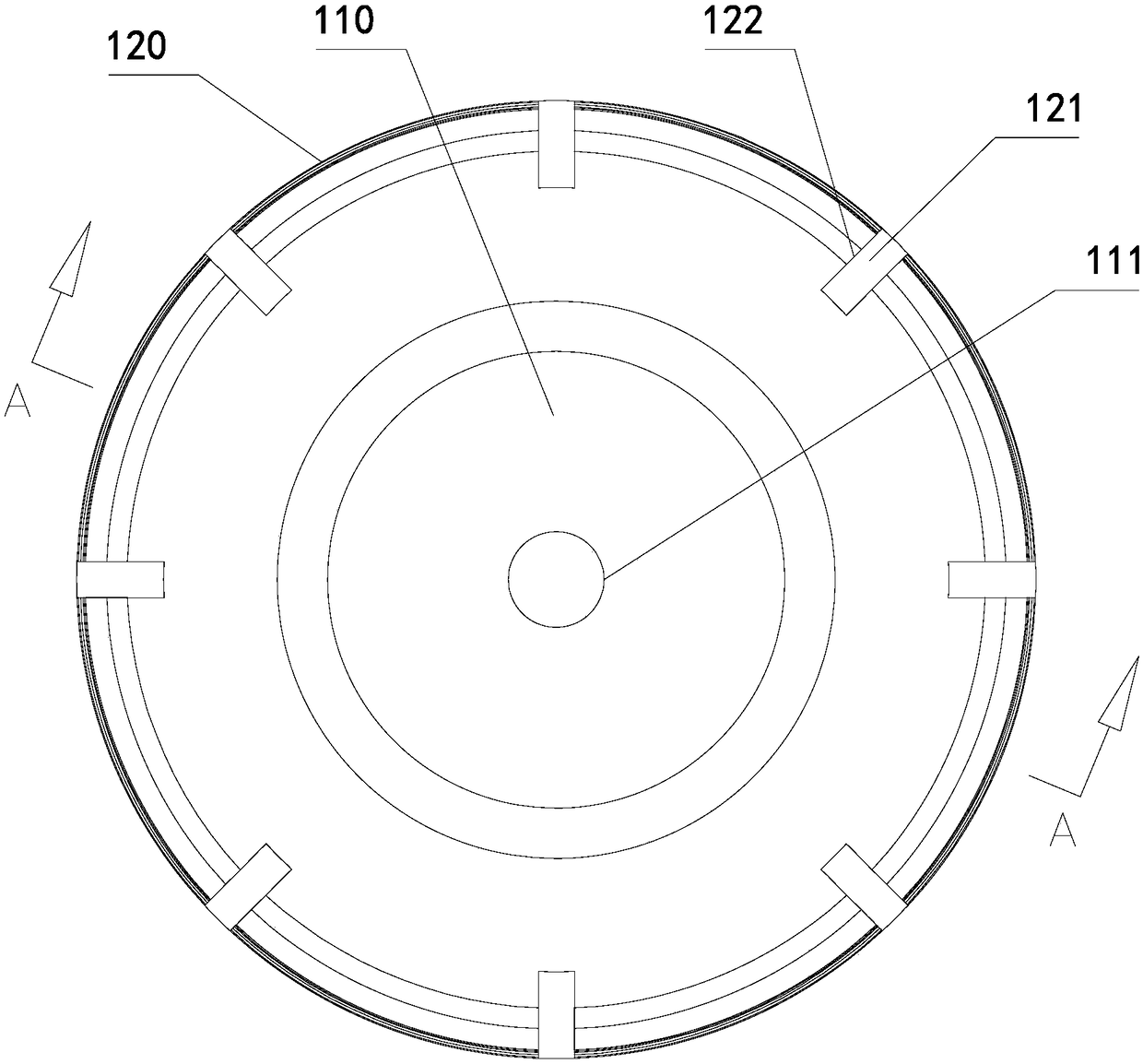

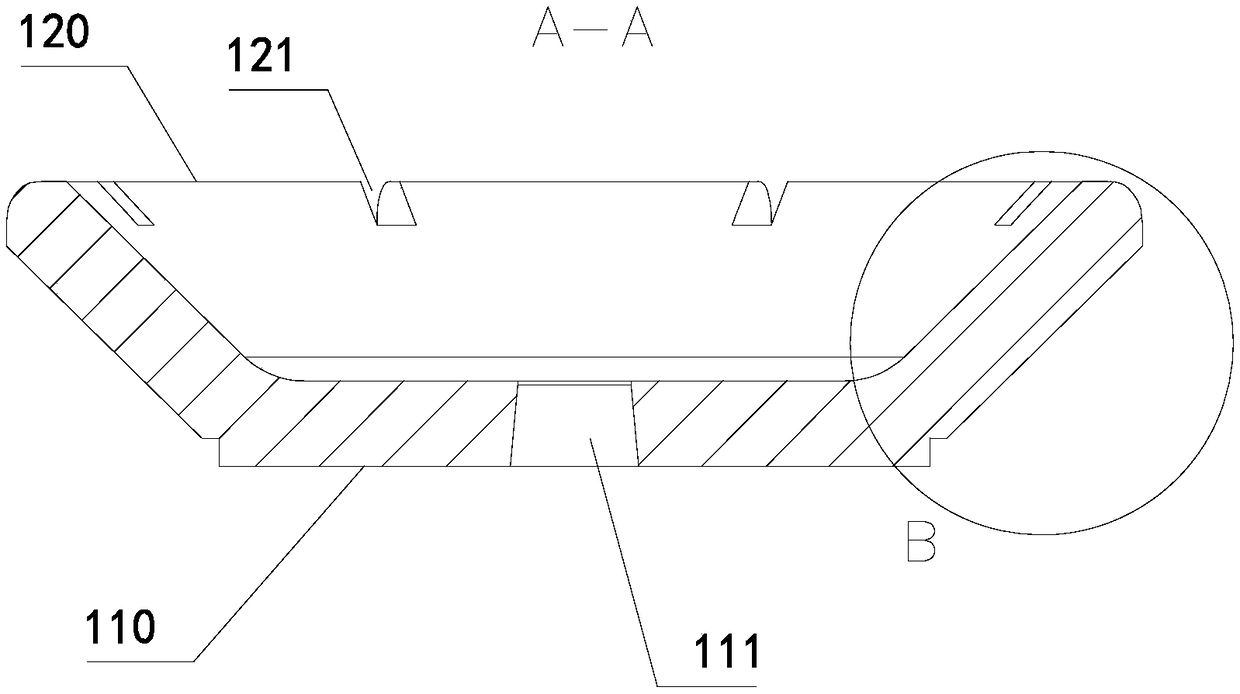

[0048] see Figure 1 to Figure 16 As shown, among them, Figure 11 , Figure 12 and Figure 13 Only a part of the main shaft of the machine tool is shown in the figure; the embodiment of the present invention provides a dynamic balancing processing system, including the main shaft of the machine tool 700, the dynamic balancing tool handle 701 and the cutter head 702; the machine tool main shaft is connected with the dynamic balancing tool handle, and the moving The balance handle is connected to the cutter head.

[0049]The dynamic balance processing system provided by this embodiment adjusts the spatial position of the overall center of gravity formed by the tool handle, cutter head and dynamic balance ring by installing objects in the counterweight hole of the dynamic balance ring, so that it remains on the tool handle On the rotation axis of the machine, it is beneficial to maintain the balance state during the rotation process, reduce the occurrence of mechanical failur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com