A kind of manufacturing method of oxide thin film transistor and oxide thin film transistor

A technology of oxide thin film and manufacturing method, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of ohmic contact, poor stability of thin film transistors, and affect the surface properties of oxide semiconductor layers, etc., to achieve The effect of good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

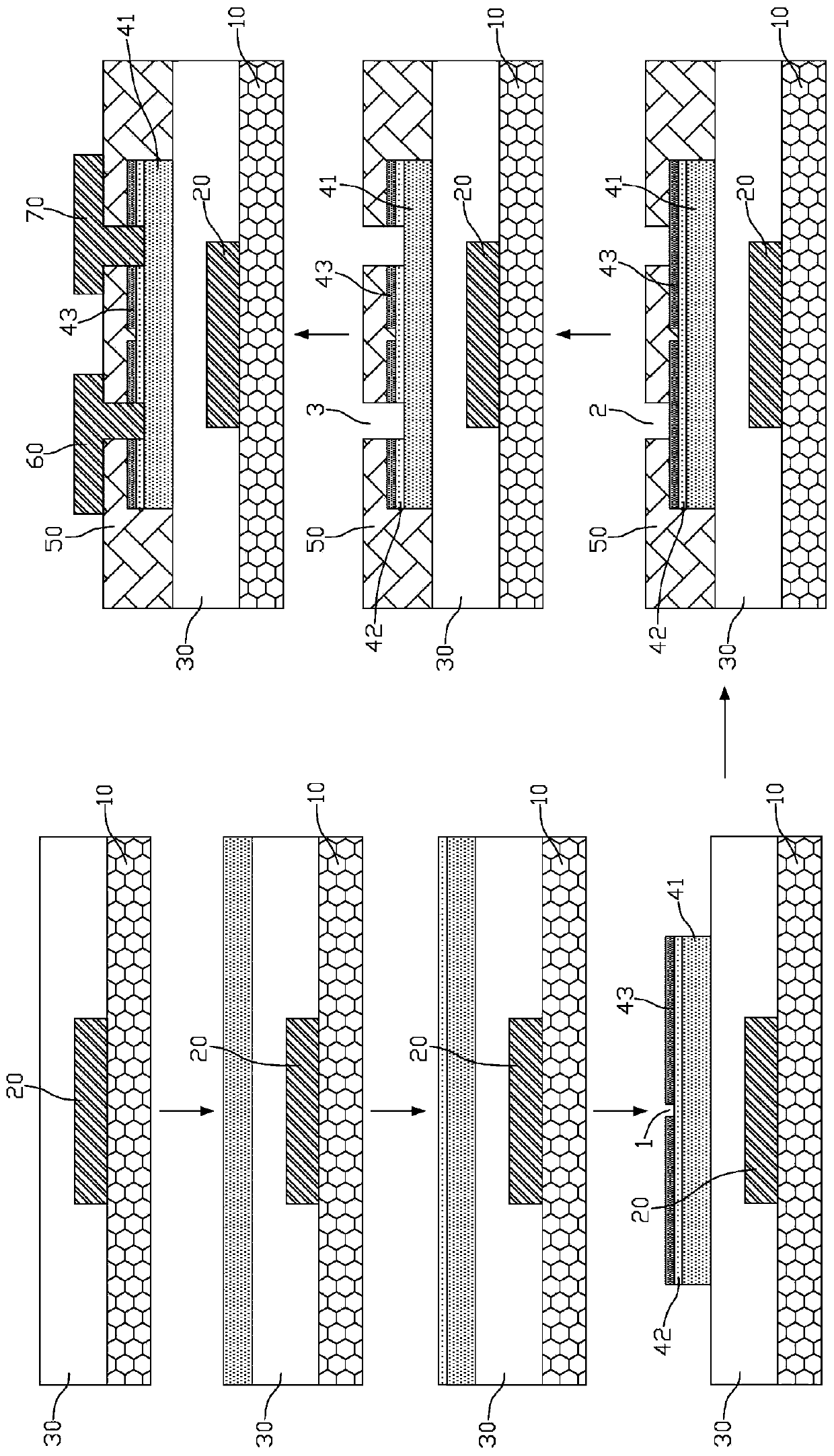

[0034] See figure 1 and figure 2 As shown, the manufacturing method of the oxide thin film transistor of this embodiment includes the following steps:

[0035] (1) sequentially forming a gate material layer and a gate insulating material layer on the substrate 10, and patterning to obtain a gate 20 and a gate insulating layer 30;

[0036] The manufacturing material of the substrate 10 includes materials such as glass, silicon wafer, quartz, plastic and silicon wafer.

[0037] The gate 20 can be formed by processes such as exposure, development, etching and sputtering, and its material can be: aluminum (Al), copper (Cu), molybdenum (Mo), titanium (Ti), silver (Ag ), gold (Au), tantalum (Ta), tungsten (W), chromium (Cr) or their alloys.

[0038] The gate insulating layer 30 can be deposited by CVD method, and its material is preferably an insulating material, including silicon dioxide, silicon nitride, silicon oxynitride or a combination of the above materials.

[0039] (2)...

Embodiment 2

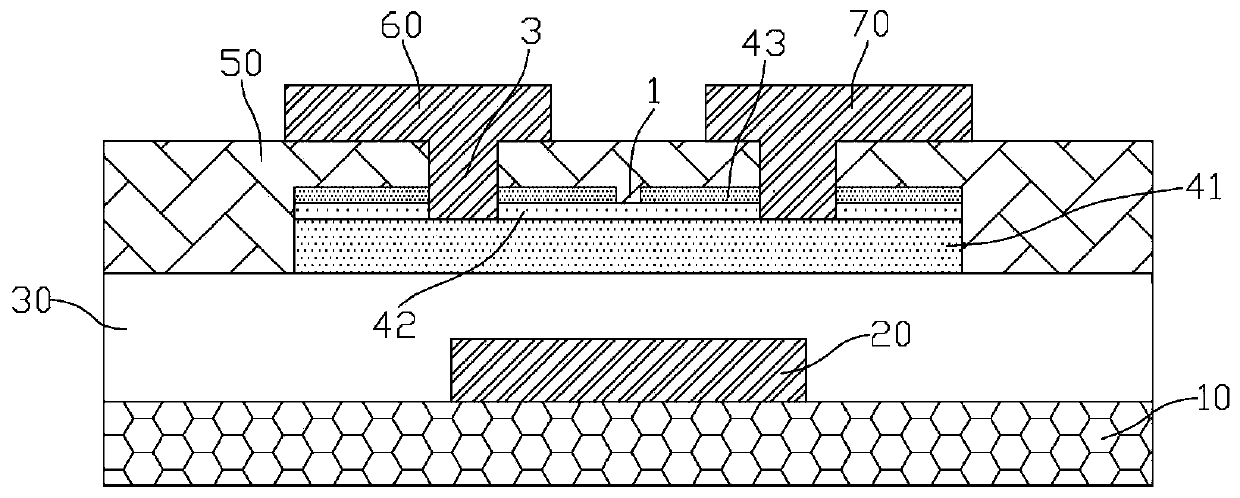

[0055] See image 3 As shown, on the basis of Embodiment 1, the method for fabricating an oxide thin film transistor in this embodiment further includes forming a fourth semi-oxide semiconductor layer between the first semi-oxide semiconductor layer 41 and the second semi-oxide semiconductor layer 42 44. The electrical conductivity of the fourth semi-oxide semiconductor layer 44 is d, where d

[0056] Yes, the material of the fourth semi-oxide semiconductor layer 44 is gallium zinc oxide, and a step is added after step (2) of Embodiment 1 to form a fourth oxide with conductivity d on the first oxide semiconductor material layer. semiconductor material layer, da, and patterned to obtain a first oxide semiconductor layer 41, a fourth oxide semiconductor layer 44, and a second oxide semiconductor layer 41. an oxide semiconductor layer 42 and a third oxide semiconductor layer 43, a first through hole 1 is formed in the third oxide semiconductor layer;

[0057] On the basis of...

Embodiment 3

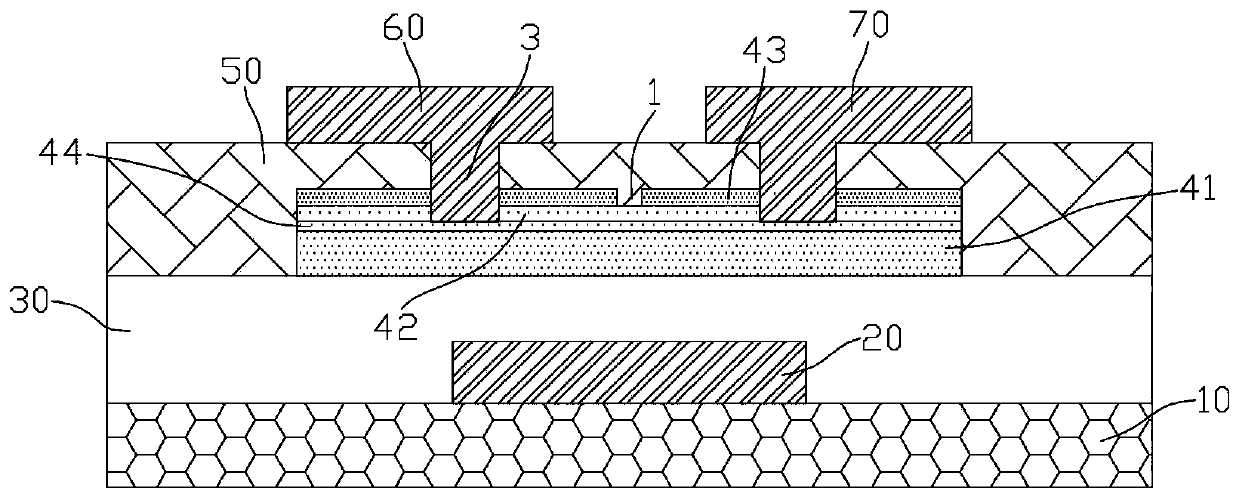

[0059] See Figure 4 As shown, on the basis of Embodiment 1, the method for fabricating an oxide thin film transistor in this embodiment further includes forming a fifth semi-oxide semiconductor layer 45 between the gate insulating layer 30 and the first semi-oxide semiconductor layer 41, and the fifth semi-oxide semiconductor layer 45 The conductivity of the oxide semiconductor layer 45 is e, where e

[0060] Yes, the material of the fifth semi-oxide semiconductor layer 45 is gallium zinc oxide, and a step is added before step (2) of Embodiment 1 to form a fifth oxide semiconductor material layer with conductivity e on the gate insulating layer 30 , ea, and pattern it to obtain the fifth oxide semiconductor layer 45, the first oxide semiconductor layer 41, the second oxide semiconductor layer 42 and the second oxide semiconductor layer. a third oxide semiconductor layer 43, a first through hole 1 is formed in the third oxide semiconductor layer;

[0061] On the basis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com