Throttling bridge capable of adjusting size of throttling hole

An orifice and adjustable technology, applied in valve details, valve operation/release devices, valve devices, etc., can solve problems such as installation errors, restrictors that cannot meet requirements, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

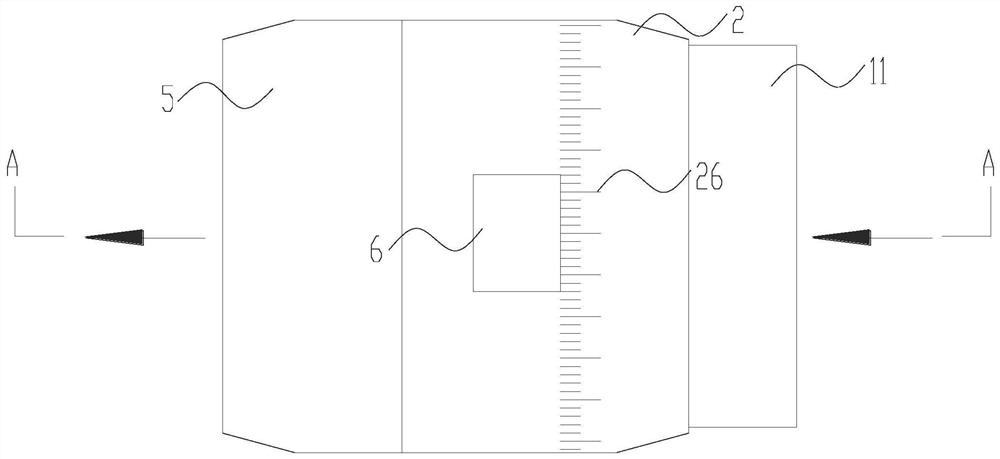

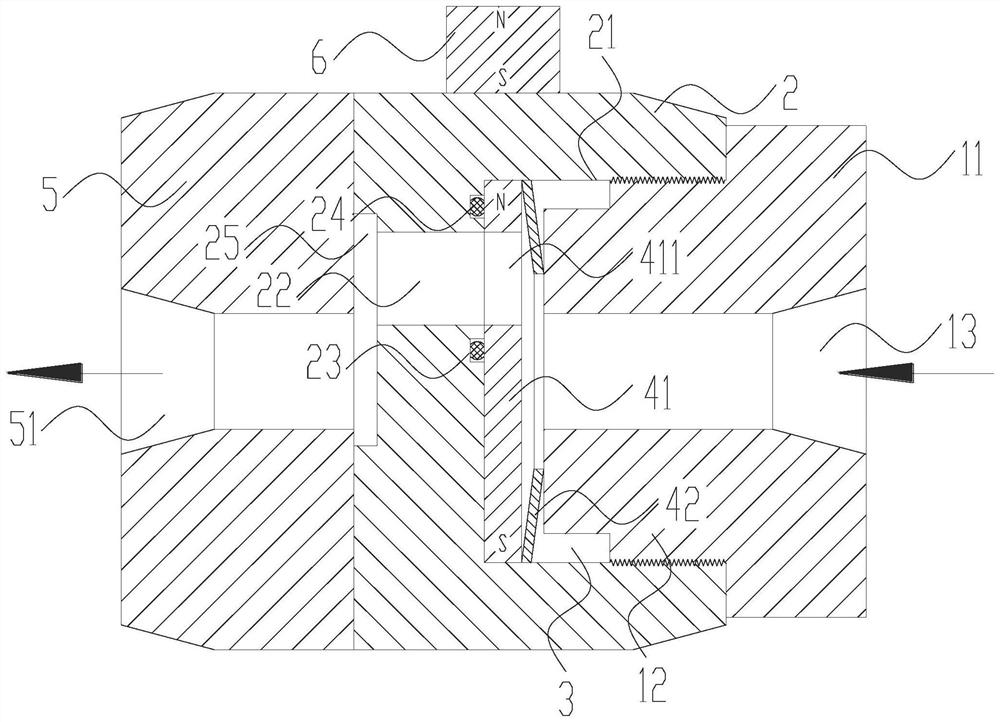

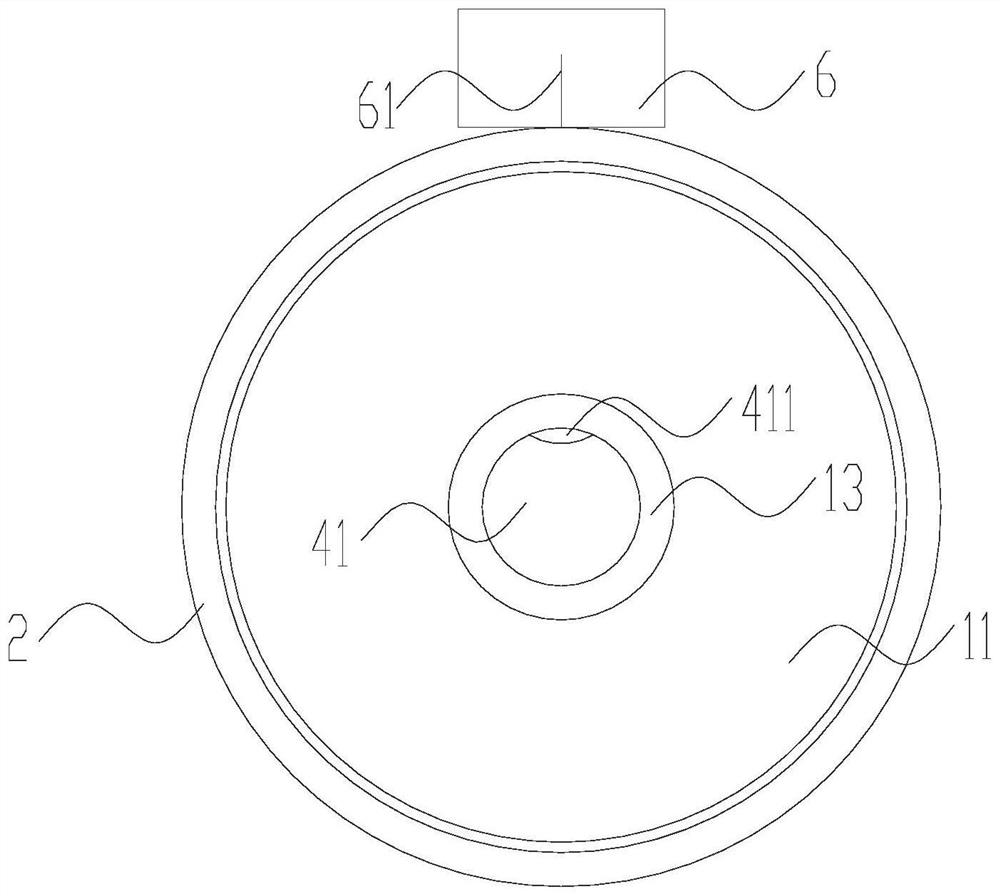

[0040] Such as Figure 1 to Figure 3 As shown, a throttle bridge with adjustable throttle hole size, including,

[0041] The air intake assembly 1 is provided with a through air intake hole 13;

[0042] The valve body assembly 2, the valve body assembly 2 is detachably and seamlessly fixed to the intake assembly 1, and the connection between the intake assembly 1 and the valve body assembly 2 is provided with an accommodation space 3; the valve body assembly 2 is provided with a penetrating air hole 22, and the accommodating space 3 communicates with the air inlet 13 and the air hole 22 respectively;

[0043] The spool assembly is rotatably arranged in the accommodating space 3, and can separate the air inlet 13 and the vent hole 22; the spool assembly is provided with a control hole 411, and as the spool assembly rotates, the flow hole and the air hole 22 are separated. The size of the communication section between the ventilation holes 22 changes; part or all of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com