Marine natural gas hydrate production method adopting double-branch-well pressure reduction assisted by water flow erosion method

A mining method and hydrate technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

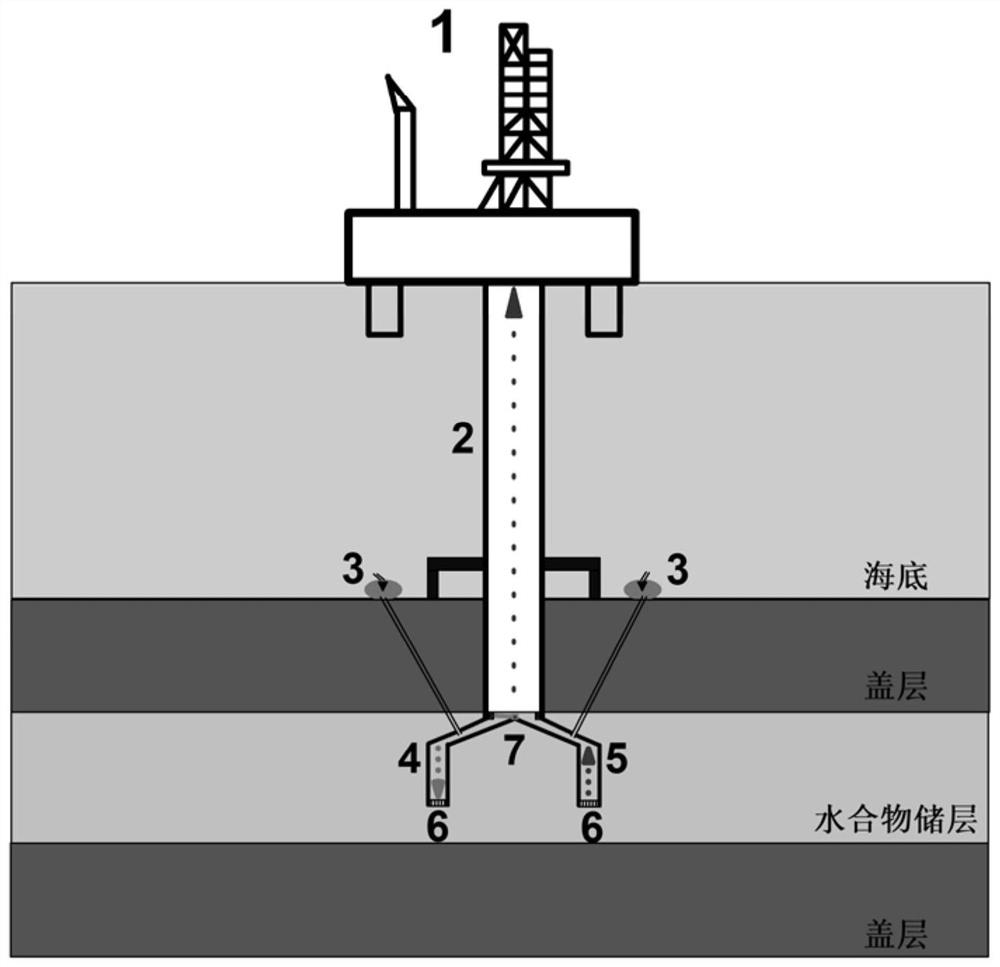

[0015] The specific implementation manners of the present invention will be further described below in conjunction with the technical solutions and accompanying drawings.

[0016] A method for exploiting marine natural gas hydrate with the aid of a water flow erosion method for double-split well depressurization, the steps are as follows:

[0017] (1) Select the drilling location, use double split wells to produce wells, and the two split wells are symmetrically distributed, such as figure 1 Mechanical sand control devices 6 are installed at the bottom of the sub-wells, and they are all connected to the centrifugal pump 3; there is a selection switch 7 in the middle of the double sub-wells. Then it is in communication with the production well 2, and the transfer switch 7 can be controlled on the offshore production platform 1;

[0018] (2) The sub-well ② is used to depressurize the production of hydrate, and transport the gas and water generated by the decomposition of hydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com