Offshore floating wind power generation cable

A cable and cable length technology, applied in power cables, floating cables, insulated cables, etc., can solve problems such as small specific gravity, poor cable flexibility and bending performance, and cables not suitable for bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

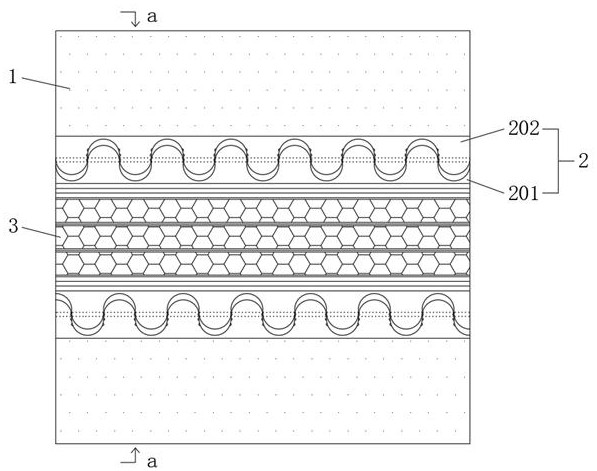

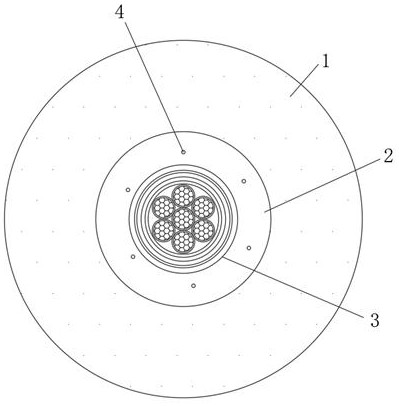

[0027] An offshore floating wind power generation cable, comprising an inner distribution layer 3, the outer part of the inner distribution layer 3 is provided with a bending unit 2 along the length direction of the cable to facilitate the overall bending of the cable, and the outer part of the bending unit 2 is provided with a device along the length direction of the cable to facilitate floating floating layer 1 on the sea surface;

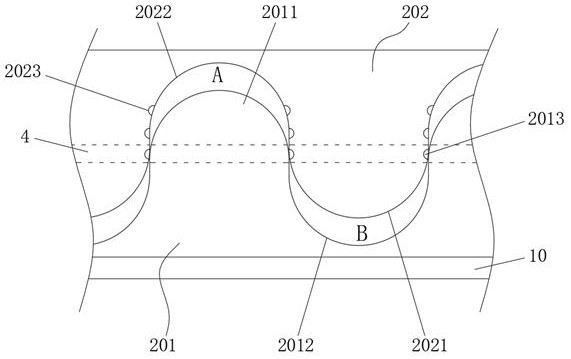

[0028] The bending unit 2 includes an inner helical layer 201 sleeved outside the inner distribution layer 3 and an outer helical layer 202 arranged on the inner wall of the floating layer 1. The inner helical layer 201 includes an inner helical convex part 2011 and an inner helical concave part 2012. The helical layer 202 includes an outer helical convex portion 2021 and an outer helical concave portion 2022, an interference fit between the outer helical convex portion 2021 and an inner helical concave portion 2012, and an interference fit betwee...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the inside of the inner spiral protrusion 2011 is provided with connecting holes 4 at equal intervals along its length direction, and the inside of the outer spiral protrusion 2021 is provided with equal intervals along its length direction. There are connecting holes 4, the connecting holes 4 are parallel to the cable core, the connecting holes 4 inside the inner spiral raised portion 2011 communicate with the connecting holes 4 inside the outer spiral raised portion 2021, and each connecting hole 4 is located on two adjacent sides. Between the raised particles 2013, the connection holes 4 are connected to each other, and the interior is filled with dry air, so that the cable as a whole is more buoyant, and it is easier to float on the sea surface. When the cable is bent as a whole, it is located The connection hole 4 inside the bending part will be squeezed, so that the connection hole 4 is closed, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com