Plastic shell inserting device capable of automatically switching plastic shell jigs

An automatic switching and insertion device technology, applied in the direction of fixed/insulated contact components, contact parts, etc., to achieve the effects of high degree of automation, wide application range and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

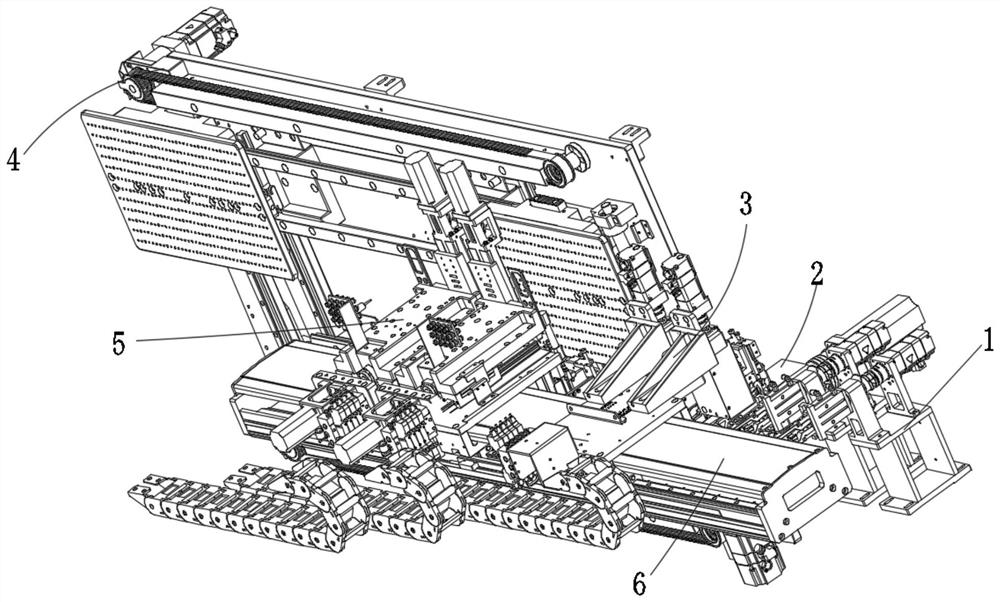

[0079] The molded case insertion device provided by the molded case provided by the present invention, including,

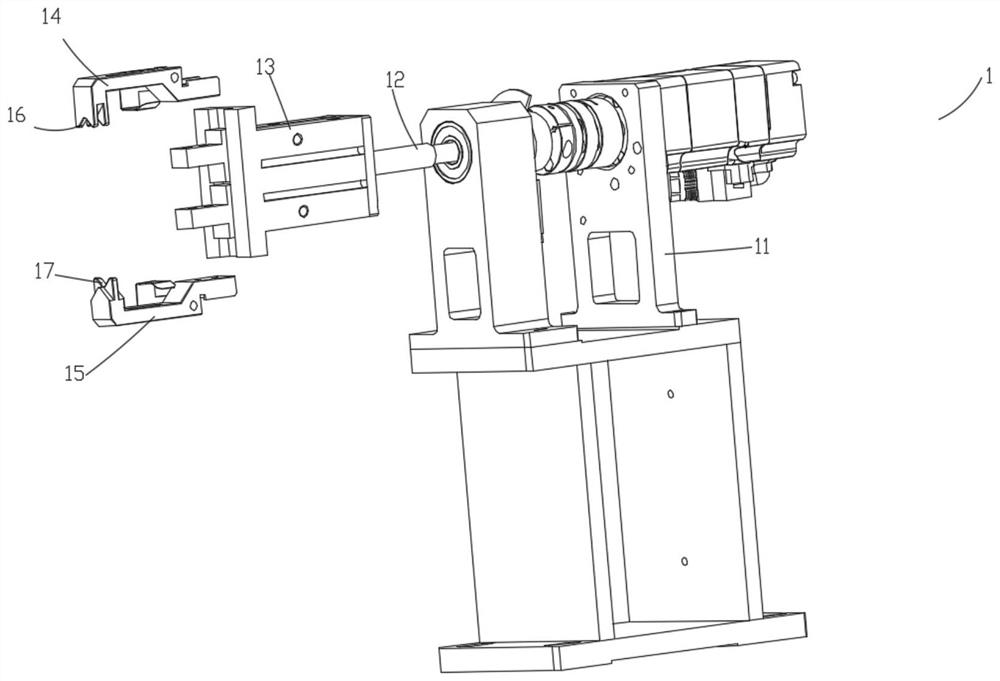

[0080] Terminal fixing unit 1, clamping the wire to be inserted;

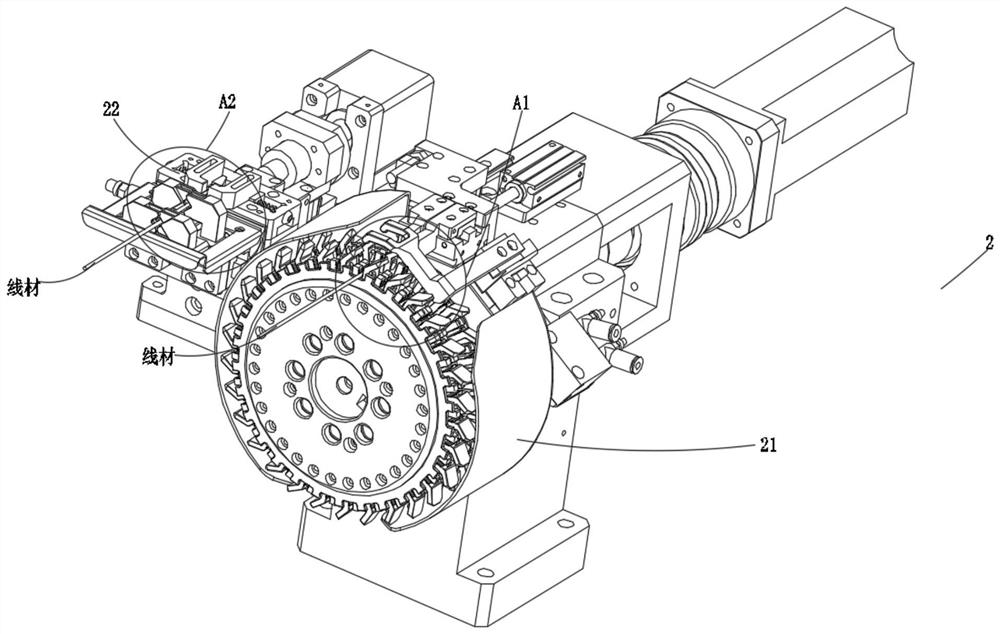

[0081] The storage line portion 2 stores a wire to be plugged in;

[0082] The transfer unit 3 stores the wire to be inserted by the terminal fixing portion 1 by the transport unit 6 to the storage line portion 2;

[0083] The plastic case fixing portion 4 stores the housing of the wire to be insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com