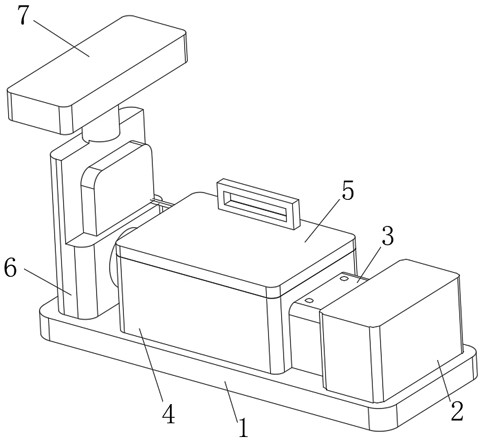

A fire hose cleaning equipment for fire engineering

A technology for fire hoses and cleaning equipment, applied in fire rescue and other directions, can solve the problems of reduced service life, trouble, decay and other problems of hoses, and achieve the effect of high fastening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

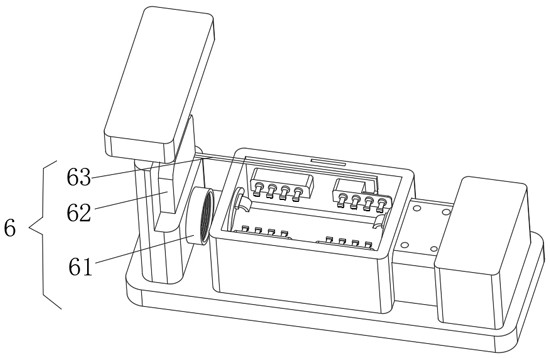

[0037] The metal piece 62 is a rectangle, and the metal piece 62 plays the role of facilitating installation and storing gas.

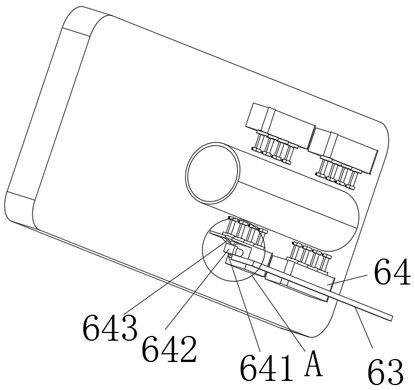

[0038] The wiping device 64 also includes a cylinder 641, the front end of the cylinder 641 is provided with a driving member 642, and the front end of the cylinder 641

[0039] The stabilization device 4 includes a hose member 41, the upper surface of the hose member 41 is provided with a lifting member 42, and the upper surface of the hose member 41 is provided with a lifting member 42.

[0040] The lifting member 42 and the stabilizing block 43 are in a mutually perpendicular state, and the lifting member 42 moves along the groove of the side wall of the stabilizing device 4.

[0042] A sliding groove is provided between the support column 33 and the driving member 34, and the driving member 34 moves upward to squeeze the balance member 35 to drive the

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com