A surface coating treatment process of a stainless steel thermal insulation container and its treatment device

A technology of thermal insulation container and surface coating, which is applied to the device, coating, spraying device and other directions for coating liquid on the surface, which can solve the problems affecting the coating processing efficiency and transportation efficiency of stainless steel thermal insulation container, waste time and manpower, and affect the stainless steel thermal insulation container. Thermal insulation container processing efficiency and other issues, to achieve the effect of improving spraying efficiency and quality, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

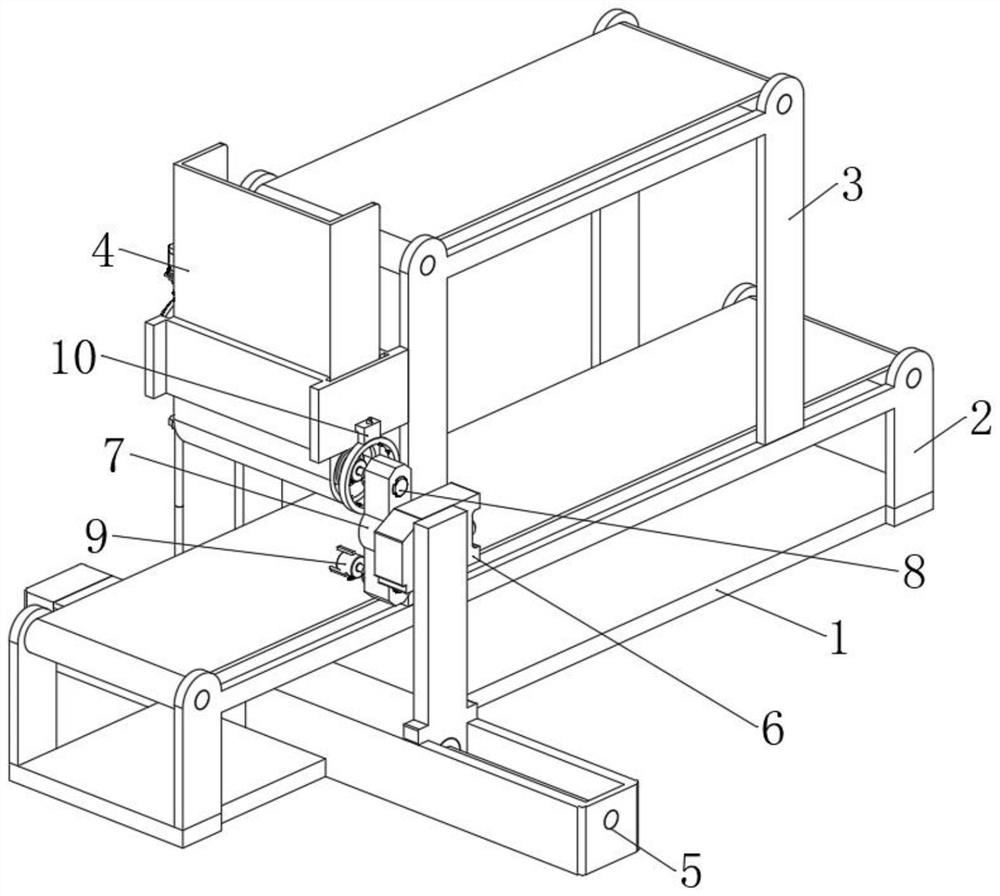

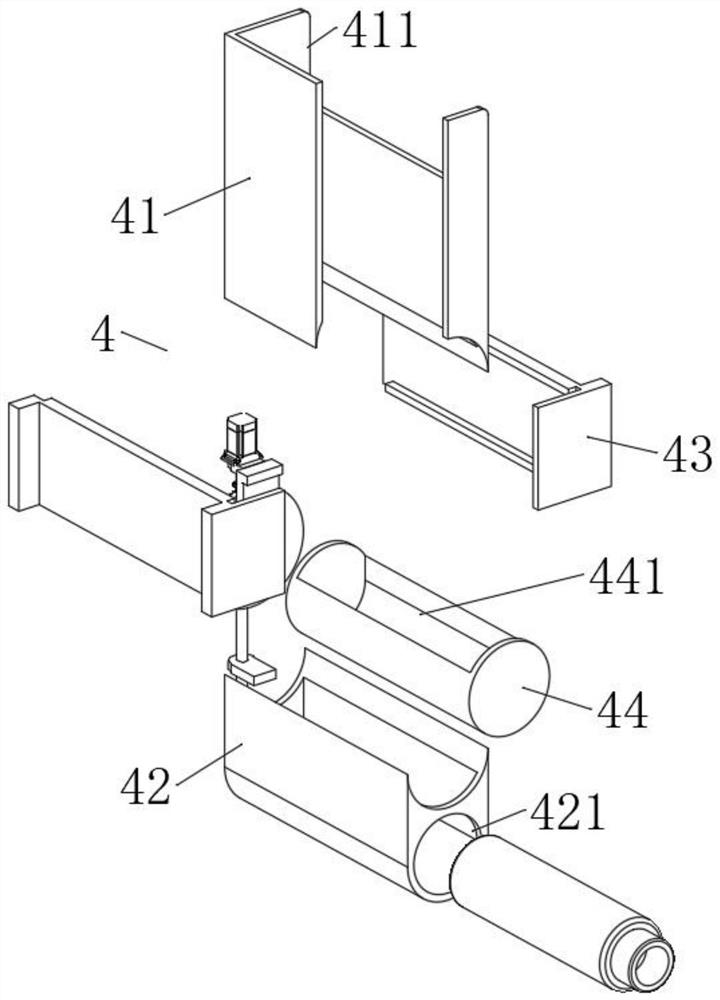

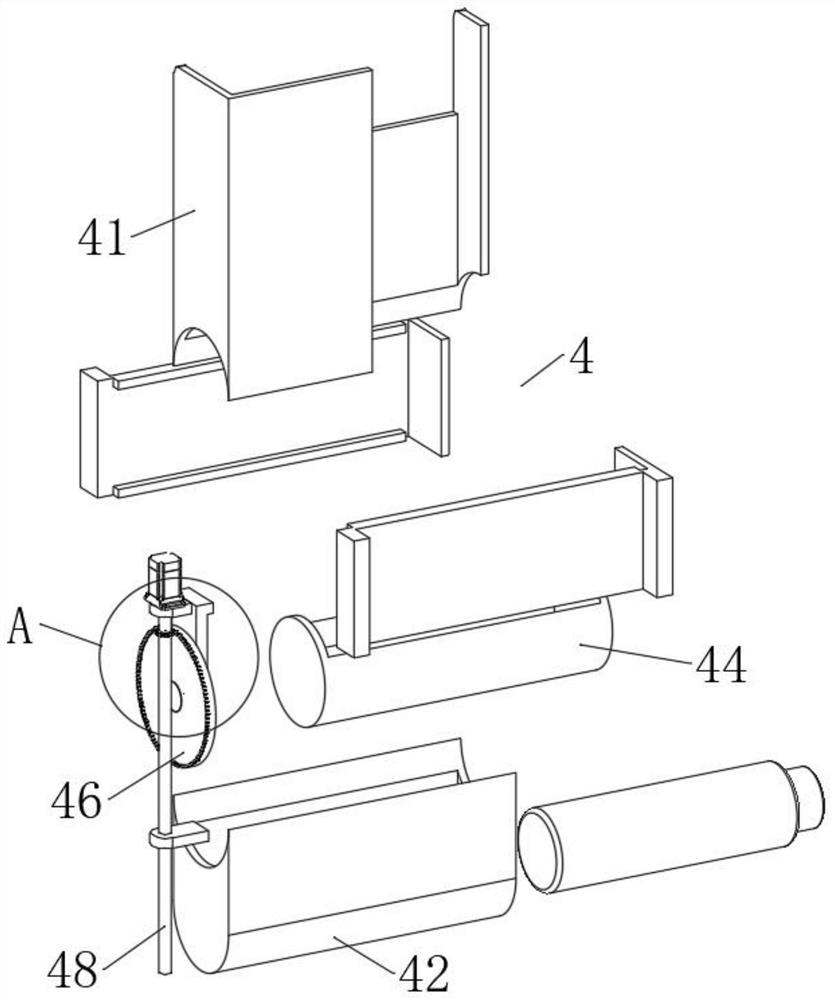

[0038] Example: as Figure 1-9 As shown, the present invention provides a surface coating treatment device for a stainless steel thermal insulation container, comprising a bottom frame 1, and a first belt conveyor 2 is fixedly installed on the top of the bottom frame 1 for conveying the coated thermal insulation container. A second transmission belt conveyor 3 is fixedly installed on the top side of a transmission belt conveyor 2 for transporting thermal insulation containers that need to be coated. The side of the bottom frame 1 away from the second transmission belt conveyor 3 is fixedly installed with a translation component 5. A feeding assembly 4 is fixedly installed on the side of the conveyor 3 close to the translation assembly 5, a rotating cylinder 6 is fixedly installed on the side of the top of the translation assembly 5 close to the feeding assembly 4, and a connecting frame 7 is fixedly installed at the driving end of the rotating cylinder 6, which connects The to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com