Continuous automatic feeding equipment

A technology of automatic feeding and equipment, applied in the directions of shaking/oscillating/vibrating mixers, dissolving, mixers, etc., can solve the problem of raw materials stuck between two adjacent blades, achieve automatic intermittent feeding, and promote uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

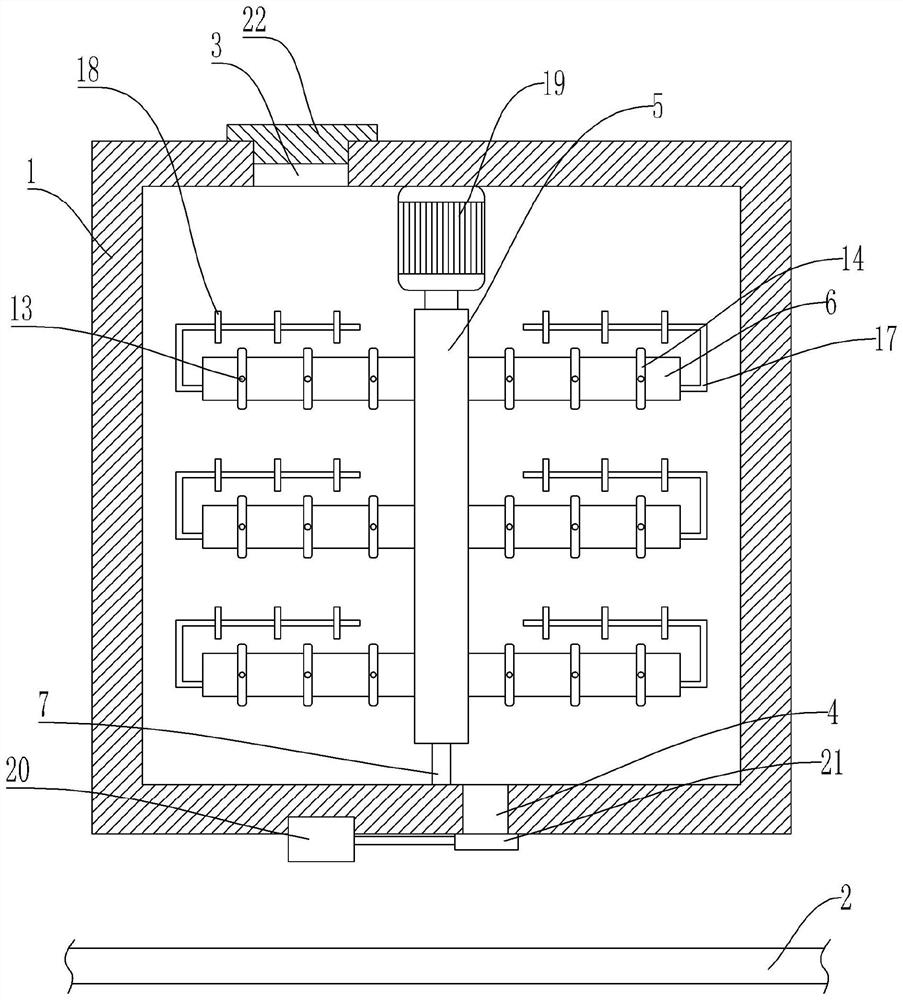

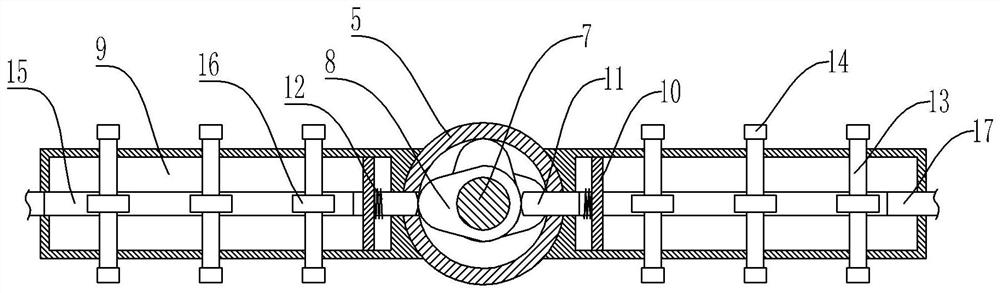

[0034] Basic as attached figure 1 And attached figure 2 Shown: a continuous automatic feeding equipment, including a machine base, a mixing box 1 and a transmission mechanism are fixedly connected to the machine base. The transmission mechanism is a commonly used belt conveyor 2, and the transmission mechanism is located below the mixing box 1.

[0035] The top of the mixing box 1 has a feed port 3, the bottom of the mixing box 1 is provided with a discharge port 4, and the feed port 3 is threadedly connected with a sealing plate 22; the mixing box 1 is provided with a rotating shaft 5 and is used to drive the rotating shaft. 5 rotating power part, the power part is a motor 19 fixedly connected to the inner top of the mixing box 1, and the output shaft of the motor 19 is fixedly connected to the rotating shaft 5. A plurality of blades 6 are affixed on the rotating shaft 5 along the axial direction of the rotating shaft 5, and a round shaft 7 is affixed to the inner bottom of...

Embodiment 2

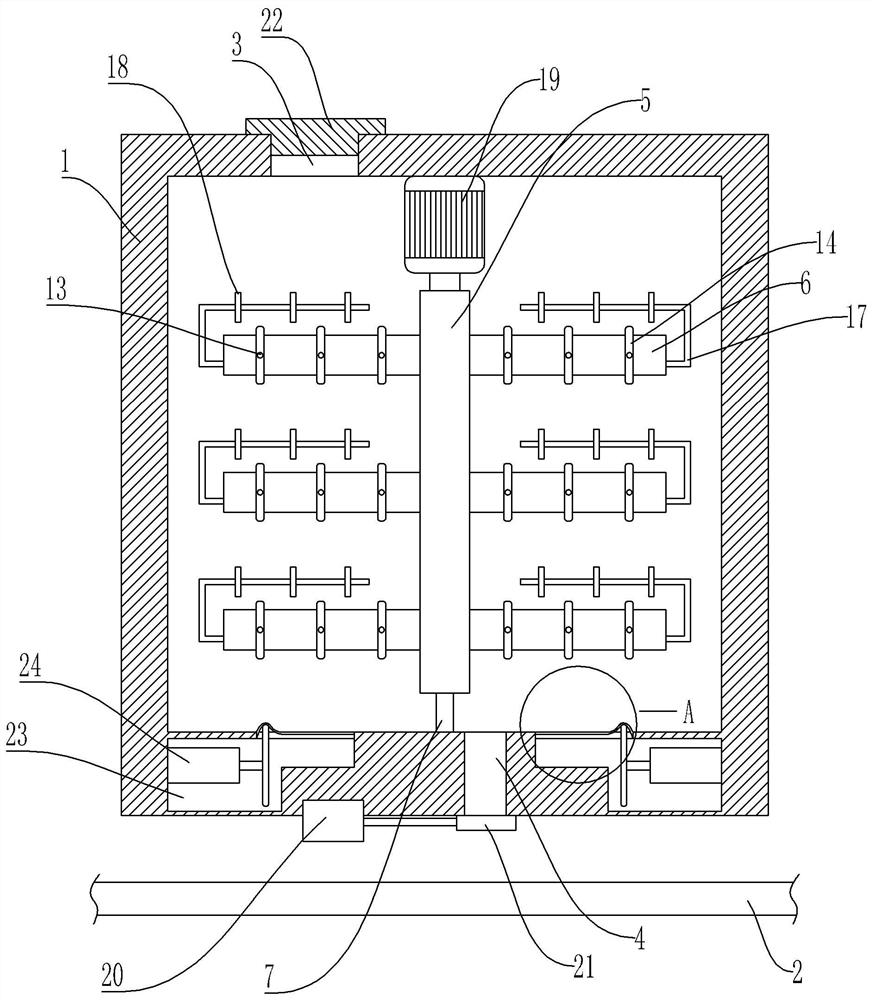

[0046] Basic as attached image 3 And attached Figure 4 As shown: the structure and implementation of Embodiment 2 are basically the same as Embodiment 1, the difference is that: there are horizontal chambers 23 inside both sides of the bottom of the mixing box 1, and the second cylinder is fixed in the horizontal chamber 23 24, and the output shaft of the second cylinder 24 is fixedly connected with a movable block 25; both sides of the bottom of the mixing box 1 are vertically provided with top grooves, and the top groove communicates with the transverse chamber 23, and the top groove is fixedly connected with a movable block 25 extrudes the elastic layer 26 protruding upwards, and in the present embodiment, the elastic layer 26 is a rubber layer.

[0047] The specific implementation process is as follows:

[0048] During the mixing of multiple raw materials, start the second cylinder 24, and the output shaft of the second cylinder 24 drives the movable block 25 to move l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com