Processing method of brim-shaped curved surface wallboard part

A processing method and surface technology, applied in the field of machining, can solve the problems of high wall thickness accuracy requirements, easy deformation of the plane, and difficulty in aligning the convex surface machining datum, so as to improve the processing efficiency, solve the uneven wall thickness, and solve the processing chatter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

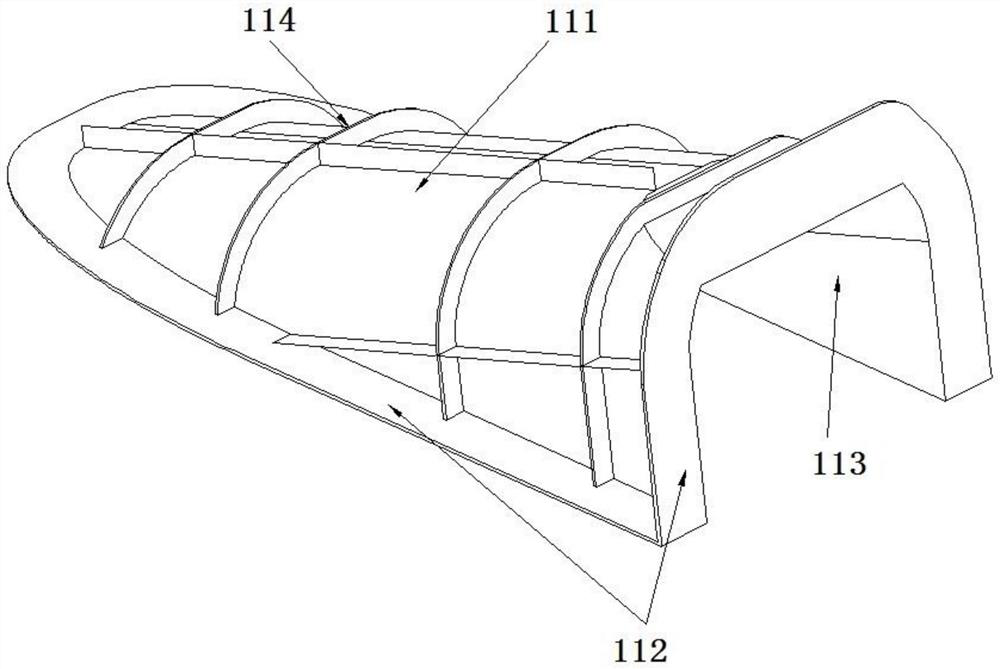

[0028] A processing method for a brim-shaped curved wall panel part, such as figure 1 As shown, the brim-shaped curved wall panel 11 is composed of a curved surface and a planar flange 112 that is increased at the edge of the curved surface and has a variable inclination angle with the curved surface. , the rear edge of the curved surface and the lower edge of the curved surface are provided with a plane flange 112, the outer surface of the brim-shaped curved wall panel is a convex surface 111, and the inner surface is a concave surface 113; the surface of the convex surface 111 is provided with ribs 114, ribs 114 It includes several transverse ribs arranged tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com