Aslant intake manifold orifice milling locating device

A technology of intake manifold and positioning device, which is applied in the direction of positioning device, metal processing equipment, metal processing machinery parts, etc., can solve the problem of unsatisfactory quality reliability and mass production ability, difficulty in ensuring product position degree requirements, and failure to meet Installation requirements and other issues, to achieve the effect of solving uneven wall thickness, meeting installation requirements, and ensuring positional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

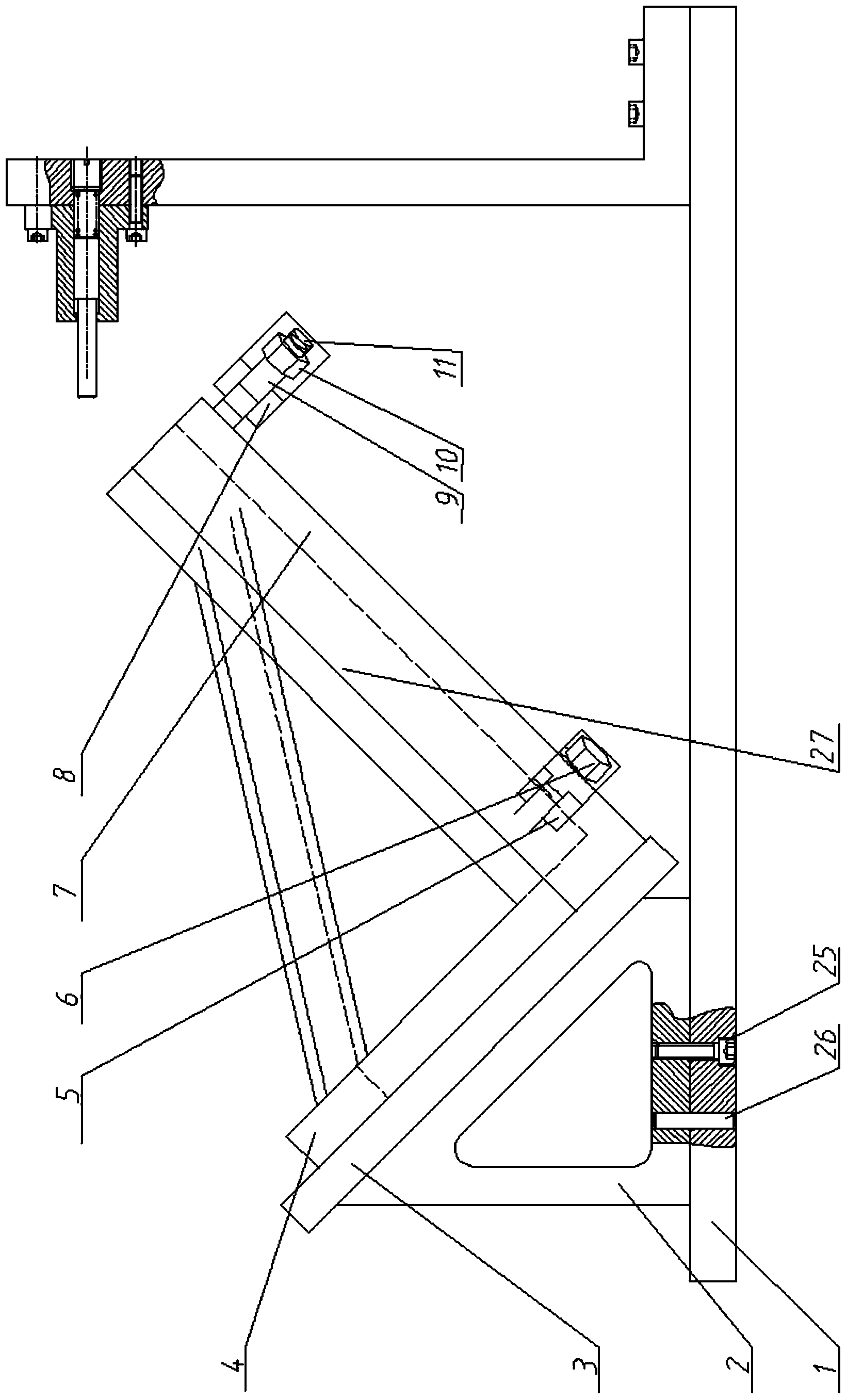

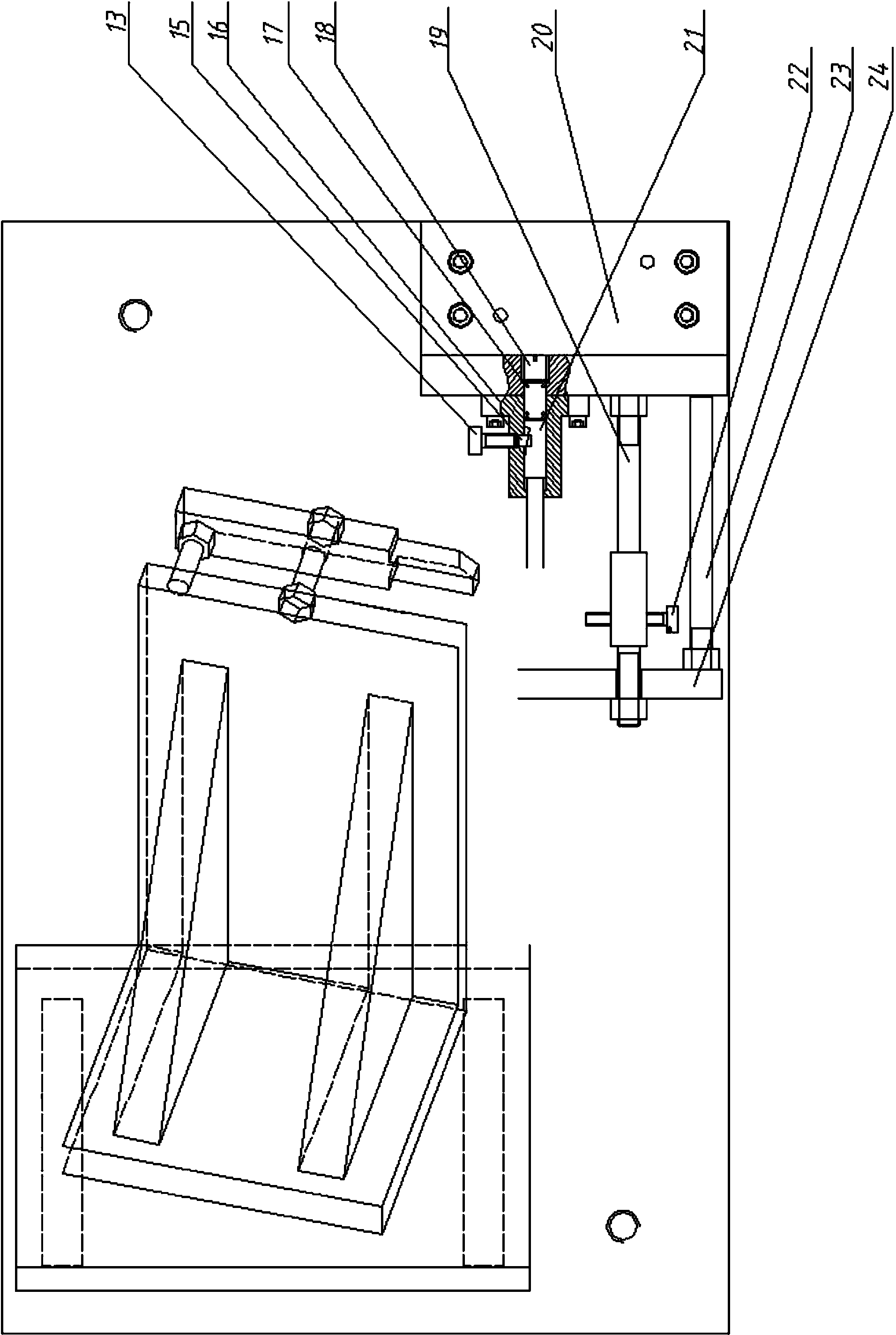

[0015] Such as figure 1 , figure 2 , a diagonal-span intake manifold nozzle milling processing positioning device, including a base plate 1, a slanting plate 2, a flat plate 3, a first angle iron 4, a first pressure plate 5, a first pressure plate screw 6, a second pressure plate 7, The third pressing plate 8, the first compression screw rod 9, the compression nut 10 and the first support rod 11, the triangular inclined plate 2 is vertically arranged on the base plate 1, the inclined plate 2 is provided with a flat plate 3, and the flat plate 3 There is a first angle iron 4, and a second pressure plate 7 is arranged on the first angle iron 4, and the second pressure plate 7 is vertically arranged with the first angle iron 4, and the first pressure plate is connected to the second pressure plate 7 through the first pressure plate screw 6 5. A third pressure plate 8 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com