Method for controlling surface rolling lines of cold-rolled deep-drawing steel for outer plate

A control method and deep drawing technology, applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve problems such as inapplicability, achieve the effect of eliminating tendency and improving surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

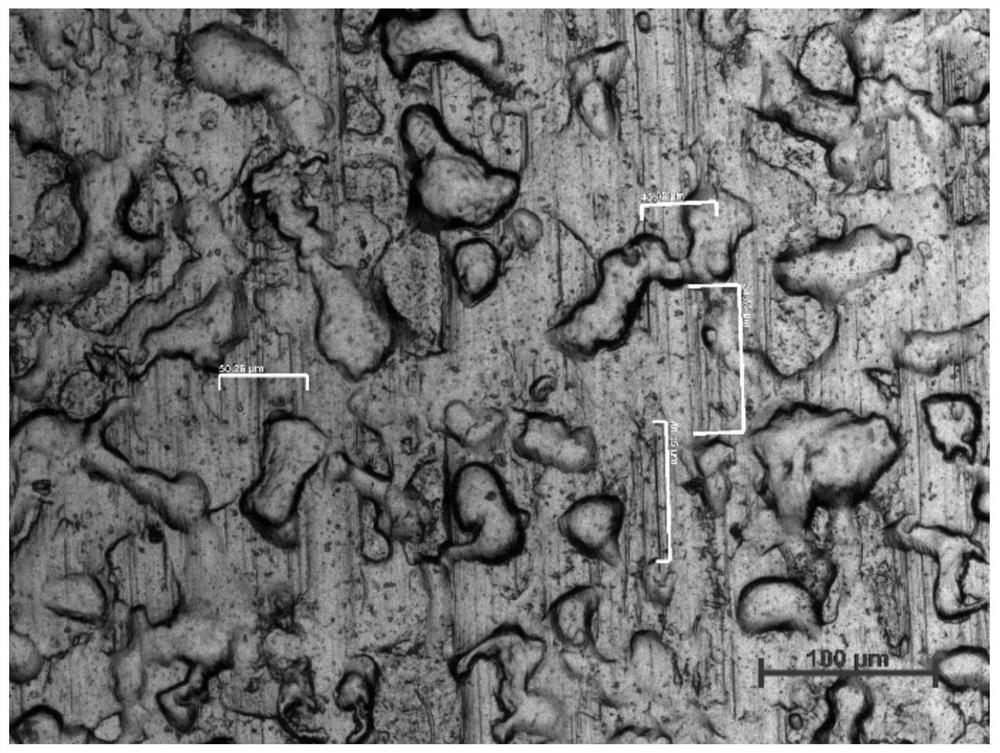

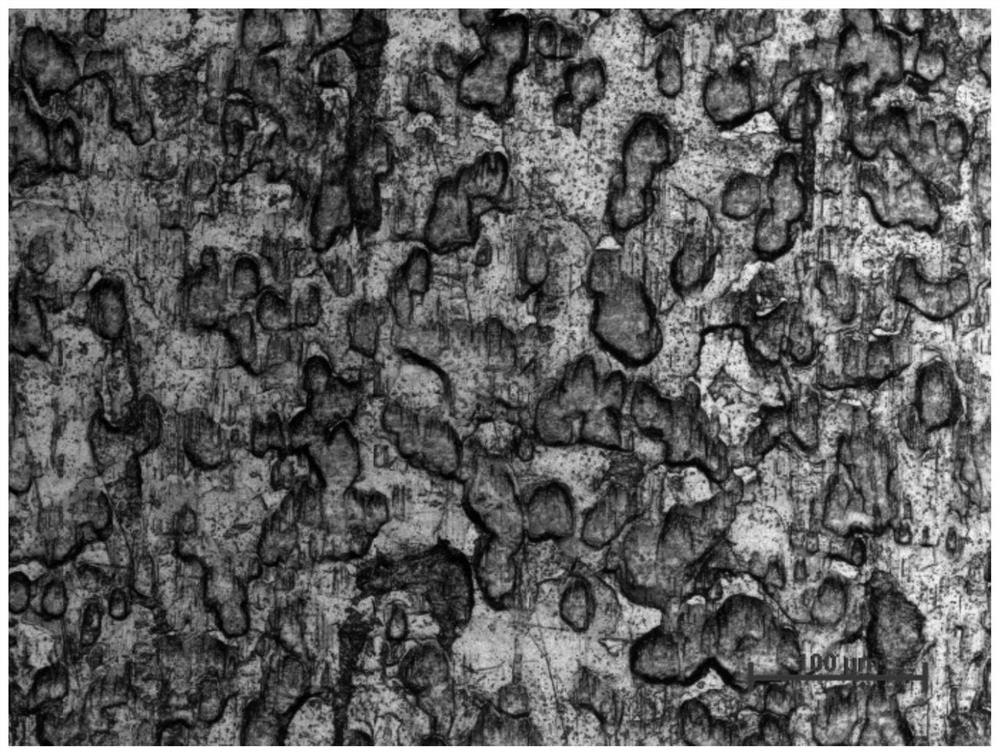

Image

Examples

Embodiment 1

[0028] The slab is smelted according to the composition of conventional DC04 cold-rolled deep-drawing steel, and the head and tail billets are changed to obtain a steel billet with a thickness of 230mm and a width of 1850mm. Lubricated rolling process, roll period and reduction in hot continuous rolling process, roll period, surface roughness and reduction in acid continuous rolling process, roll surface roughness, peak number, roll diameter difference and pass leveling force in continuous annealing process and other parameters are controlled to improve the surface texture of the finished product. The specific steps are as follows:

[0029] (1) The hot continuous rolling process adopts seven-stand continuous rolling, and the F2~F6 stands are put into rolling lubrication. 30ml / min, the oil volume of the upper rack of F6 is set to 30ml / min, and the oil volume of the lower rack is set to 35ml / min; the roughness of the upper machine of the F7 working roll is 0.81μm; the reduction ...

Embodiment 2

[0036] The slab is smelted according to the composition of conventional DC06 cold-rolled deep-drawing steel, and the head and tail billets are changed to obtain a steel billet with a thickness of 230mm and a width of 1850mm. Lubricated rolling process, roll period and reduction in hot continuous rolling process, roll period, surface roughness and reduction in acid continuous rolling process, roll surface roughness, peak number, roll diameter difference and pass leveling force in continuous annealing process And other parameters are controlled to improve the surface texture of the finished product. The specific steps are as follows:

[0037] (1) The hot continuous rolling process adopts seven-stand continuous rolling, and the F2-F6 stands are put into rolling lubrication. 30ml / min, the oil volume of the upper rack of F6 is set to 30ml / min, and the oil volume of the lower rack is set to 35ml / min; the roughness of the upper machine of the F7 working roll is 0.79μm; the reduction ra...

Embodiment 3

[0044] The slab is smelted according to the composition of conventional DC03 cold-rolled deep-drawing steel, and the head and tail billets are changed to obtain a steel billet with a thickness of 230mm and a width of 1500mm. Lubricated rolling process, roll period and reduction in hot continuous rolling process, roll period, surface roughness and reduction in acid continuous rolling process, roll surface roughness, peak number, roll diameter difference and pass leveling force in continuous annealing process and other parameters are controlled to improve the surface texture of the finished product. The specific steps are as follows:

[0045] (1) The hot continuous rolling process adopts seven-stand continuous rolling, and the F2~F6 stands are put into rolling lubrication. 30ml / min, the oil volume of the upper rack of F6 is set to 30ml / min, and the oil volume of the lower rack is set to 35ml / min; the roughness of the upper machine of the F7 working roll is 0.77μm; the reduction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com