Bottom die slope adjusting device

A technology for adjusting device and slope, which is applied in the direction of measuring device, measuring inclination, formwork/template/work frame, etc., which can solve the problems of inability to quickly locate, incorrect installation slope of beam-shaped bottom form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

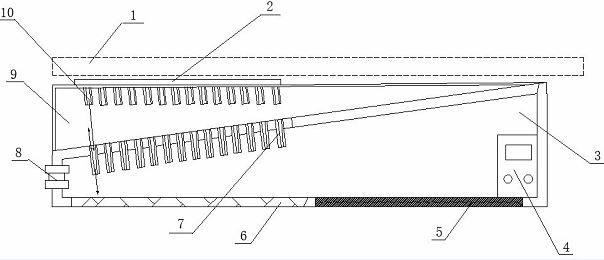

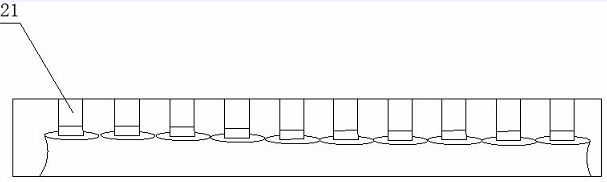

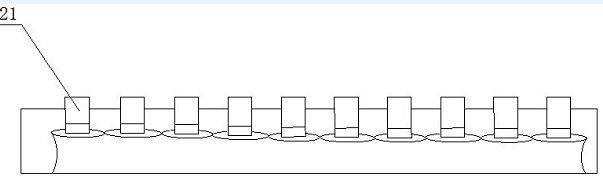

[0023] Please also refer to the attached figure 1 to the attached image 3 , this embodiment provides a bottom mold slope adjustment device, which is mainly used to solve the problem that the existing beam-shaped bottom mold cannot be quickly positioned and adjusted when the slope of the beam-shaped bottom mold is installed incorrectly. At the stage of experimental use, it should be noted that the beam-shaped bottom form in this application is formed by laying beam-shaped structural members 1 .

[0024] The specific embodiment of the present invention is as follows, including the first module 3 and the second module 9 arranged in sequence from top to bottom in the functional cavity for optical feedback work, the first module 3 and the second module 9 are fixedly connected, fixedly connected The methods include limit connection, screw fastening connection, etc. The preferred implementation mode of this embodiment is to adopt the thread fastening connection method, which can ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com