Continuously variable Mach number control method at supersonic speed and constant total pressure in large open jet wind tunnel

A Mach number and wind tunnel technology, which is applied in the field of wind tunnel testing and can solve the problems of total pressure oscillation of the assembly, reduction of the intake air flow of the pressure regulating valve, and total pressure fluctuation of the stable section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

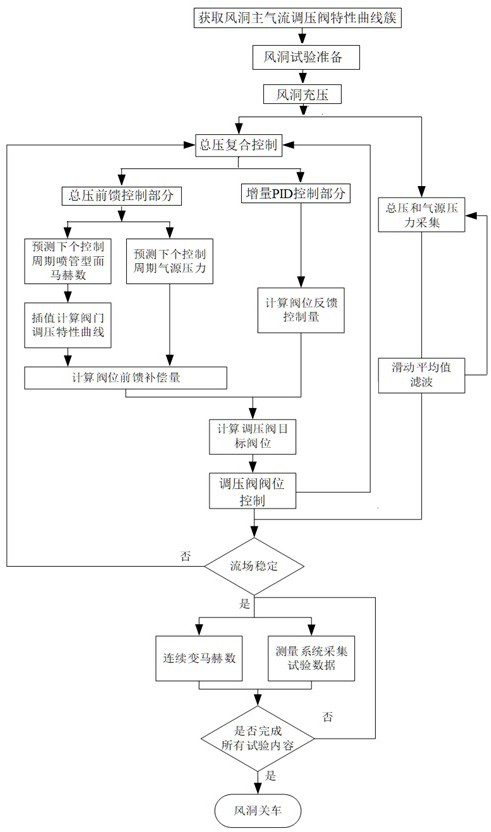

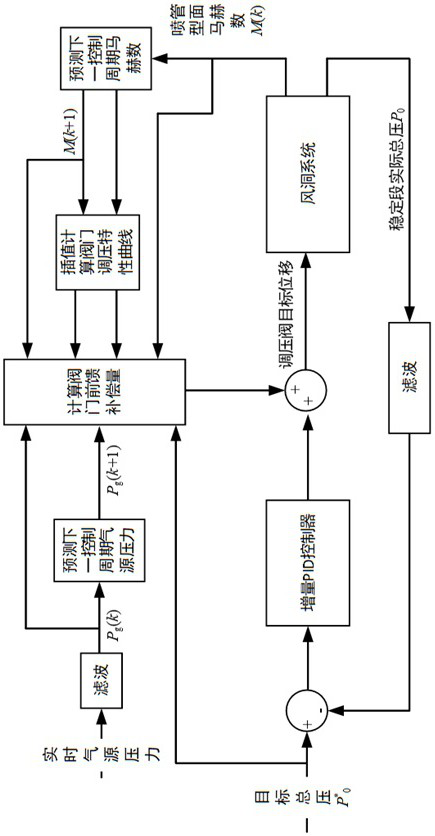

[0044] Such as figure 1 As shown, the supersonic constant total pressure continuous variable Mach number control method of the large-scale open jet wind tunnel of the present invention comprises the following steps:

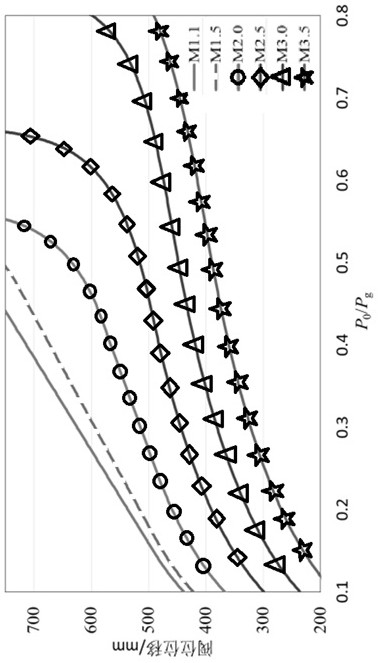

[0045] S1. Obtain the cluster of characteristic curves of the main airflow regulator valve in the wind tunnel;

[0046] Through theoretical analysis, or according to the actual operation test, obtain the characteristic curve cluster of the pressure regulating valve at a certain Mach number interval within the range of the continuously variable Mach number of the wind tunnel;

[0047] S2. Preparation for wind tunnel test;

[0048] Determine the relevant test procedures and test parameters, including the initial Mach number , final Mach number , target total pressure ; The wind tunnel nozzle profile is placed at the initial Mach number the corresponding profile;

[0049] S3. Wind tunnel charging;

[0050] Open the pressure regulating valve to the preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com