Equipment for automatically loading toothbrushes into grooves of packaging boxes

A technology of automatic loading and packing, applied in packaging, packaging protection, transportation and packaging, etc., to achieve the effect of adjusting the end of the toothbrush, stabilizing the mechanical mechanism, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

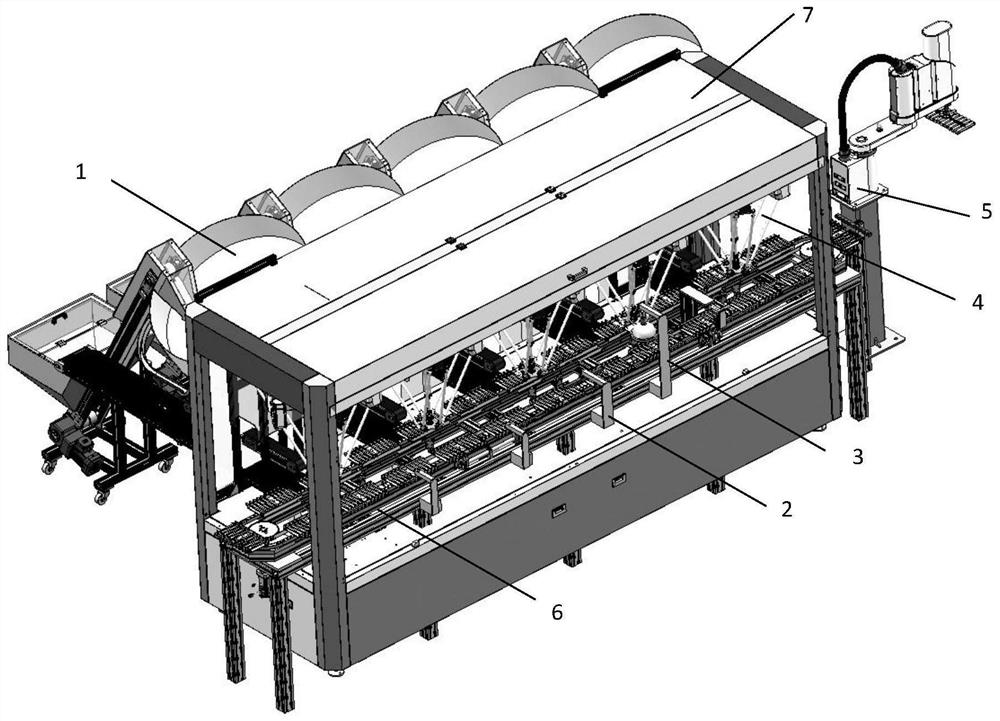

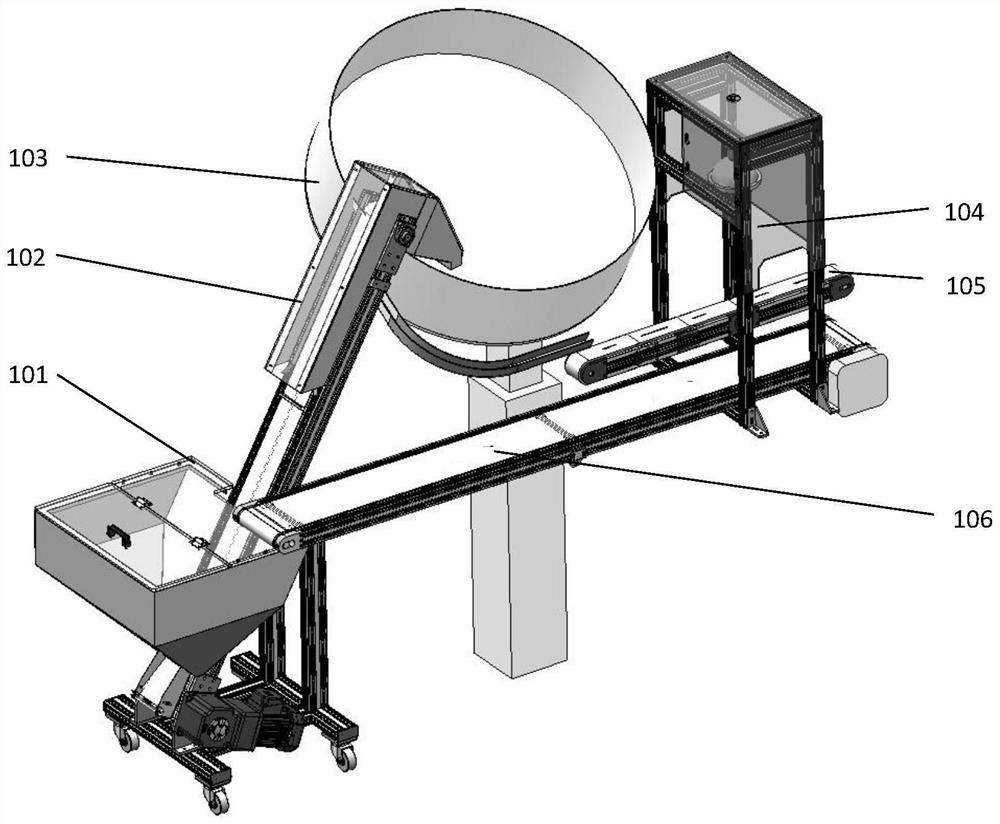

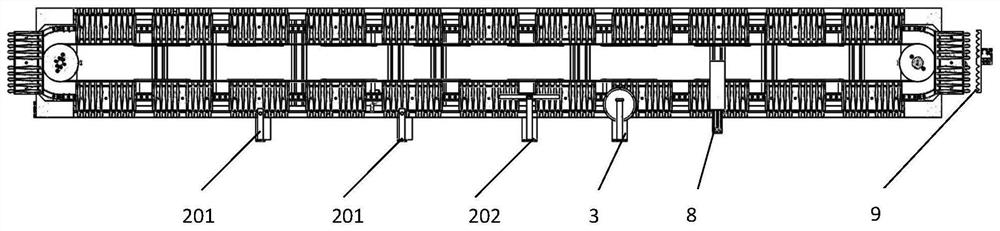

[0030] Such as figure 1 , figure 2 , image 3 As shown, a toothbrush is automatically loaded into the groove of the packaging box, including a circular conveyor line 6, a toothbrush feeding part 1, a second attitude adjustment mechanism 2, a rejecting mechanism 8, and a positioning mechanism 9 along the moving direction of the circular conveyor line 6 Arranged in sequence, the toothbrush feeding part 1 comprises a lifting part 102, a centrifugal disc 103 and a single-row conveying line 105, the output end of the lifting part 102 is connected with the feed inlet of the centrifugal disc 103, and the discharge port of the centrifugal disc 103 is connected with the single-row conveying line 105 connected to the input end, the first posture detection mechanism 104 is set above the single-row conveying line 105 and downstream of the centrifugal disc 103, the input end of the single-row conveying line 105 is set on one side of the circular conveying line 6, and the parallel robot 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com