Phenolic resin, preparation method thereof and phenolic resin product

A technology for phenolic resin and products, applied in the field of phenolic resin and its preparation, phenolic resin products, can solve the problems of easy occurrence of gel, endanger human health, physical blending, etc., and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

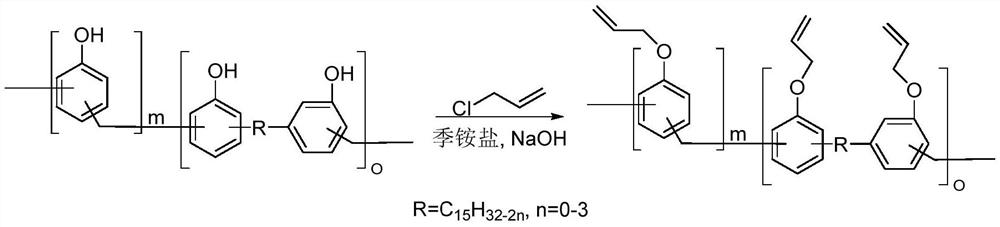

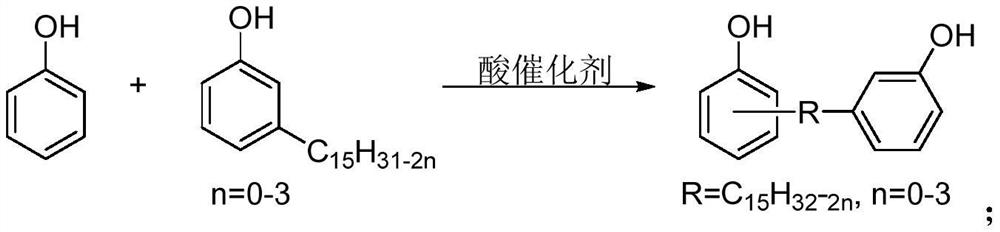

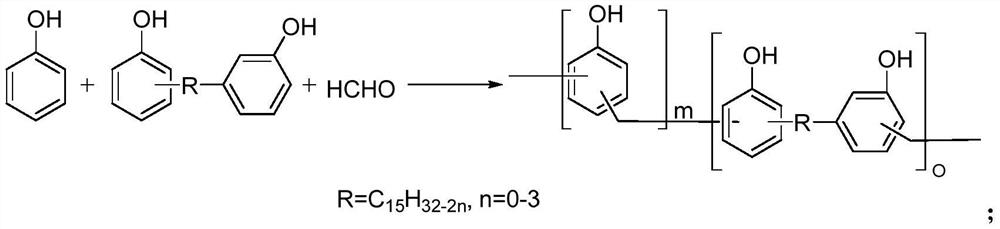

Method used

Image

Examples

preparation example 1

[0048] Put 1000kg of preheated and melted phenol into the high-level metering tank with a special pump, and meter it into the reaction kettle, then add 200kg of cashew nut oil and 3kg of p-toluenesulfonic acid, raise the temperature to 150°C and keep it warm for 3 hours, then drop the temperature to 100°C 650kg of 37% formaldehyde solution was added dropwise within 1 hour. After the dropwise addition of formaldehyde was completed, it was kept for 1 hour, and then dehydrated to 150°C under normal pressure. Add 3.13 kg of barium hydroxide, stir for 30 minutes, vacuum dehydrate to 180°C (vacuum degree less than 0.09Mpa) and keep for 2 hours to obtain cashew nut oil modified phenolic resin A.

preparation example 2

[0050] Put 1000kg of preheated and melted phenol into the high-level metering tank with a special pump, and measure it into the reaction kettle, then add 210kg of cashew nut oil and 3.3kg of p-toluenesulfonic acid, raise the temperature to 130°C and keep it warm for 5 hours, then drop the Add 630kg of 37% formaldehyde solution, and complete the dropwise addition within 1 hour. After the dropwise addition of formaldehyde is completed, keep warm for 1 hour, and then dehydrate to 150°C under normal pressure. Add 3.44 kg of barium hydroxide, stir for 30 minutes, vacuum dehydrate to 180°C (vacuum degree less than 0.09Mpa) and keep for 2 hours to obtain cashew nut oil modified phenolic resin B.

preparation example 3

[0052] Put 1000kg of preheated and melted phenol into the high-level metering tank with a special pump, and measure it into the reaction kettle, then add 400kg of cashew nut oil and 5kg of dodecylbenzenesulfonic acid, heat up to 150°C and keep it for 4 hours, then cool down to 100°C Finally, 600kg of 37% formaldehyde solution was added dropwise, and the dropwise addition was completed within 1 hour. After the dropwise addition of formaldehyde, it was kept for 1 hour, and then dehydrated to 150°C under normal pressure. Add 1.2 kg of calcium hydroxide, stir for 30 minutes, vacuum dehydrate to 180°C (vacuum degree less than 0.09Mpa) and keep for 2 hours to obtain cashew oil modified phenolic resin C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap