Construction method of cast-in-place pier of municipal viaduct

A construction method and technology for viaducts, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as affecting the construction efficiency of bridge piers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

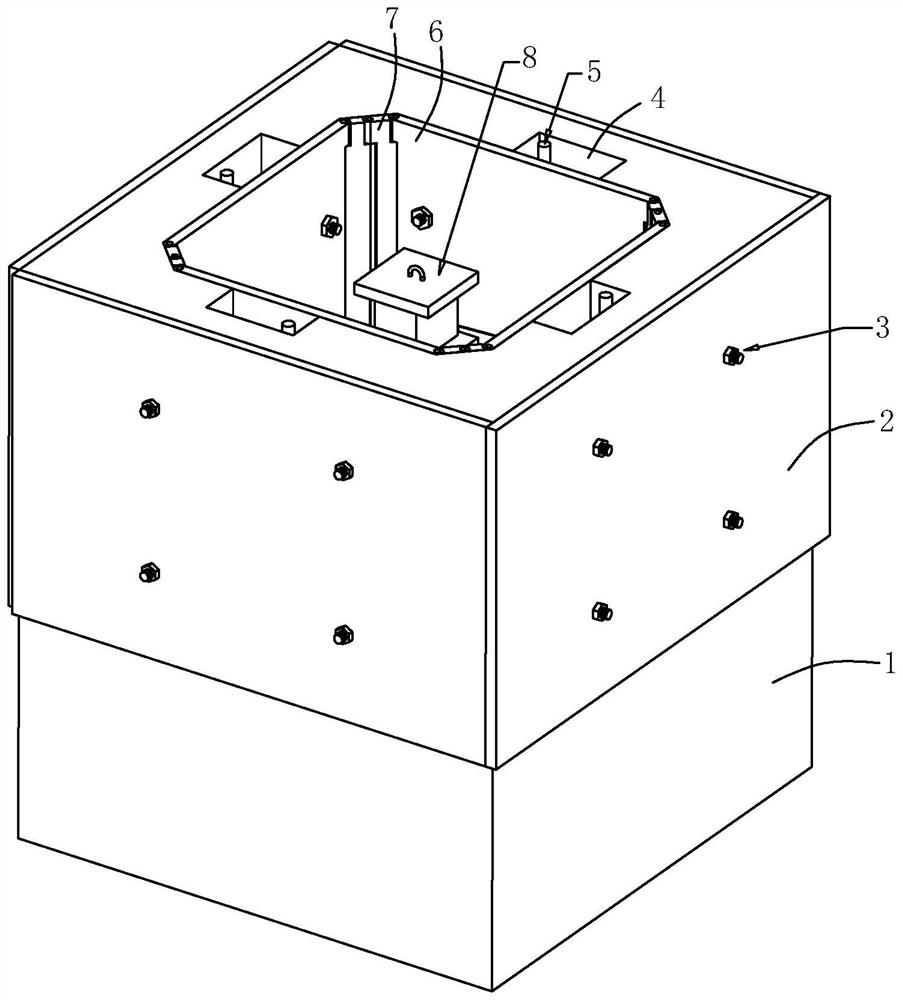

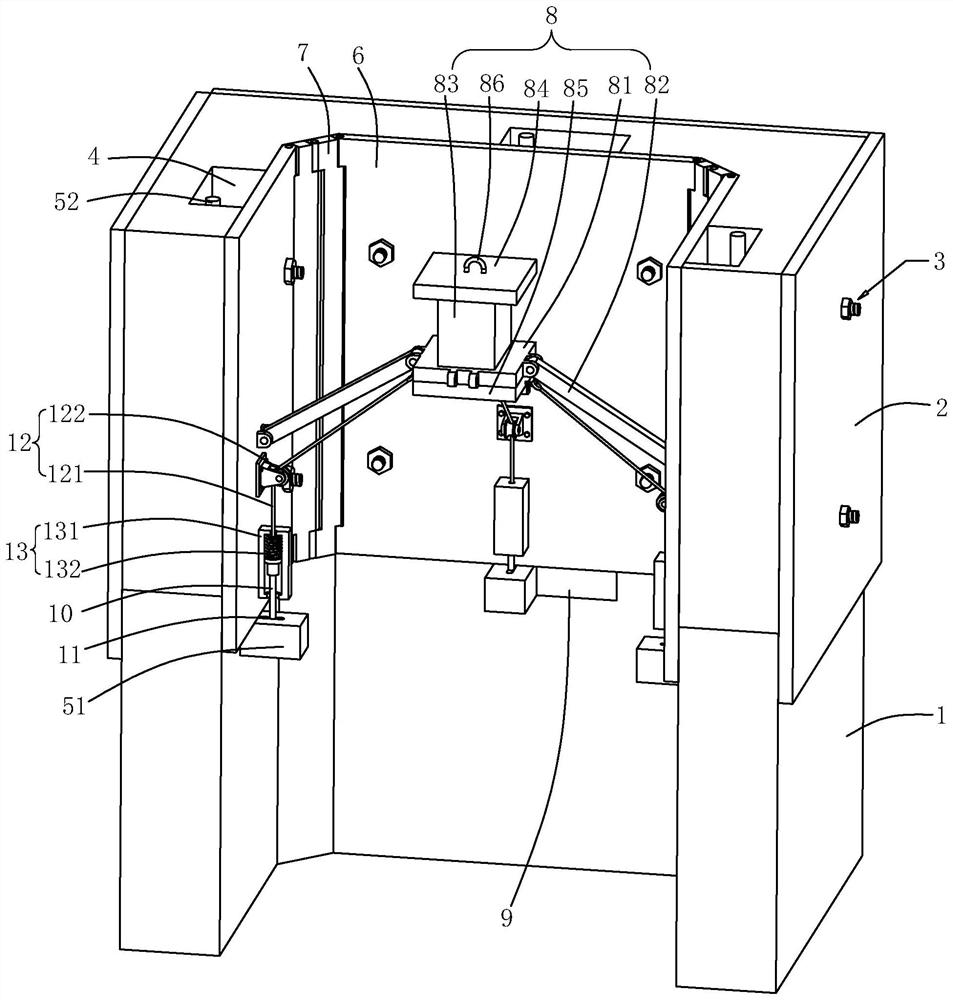

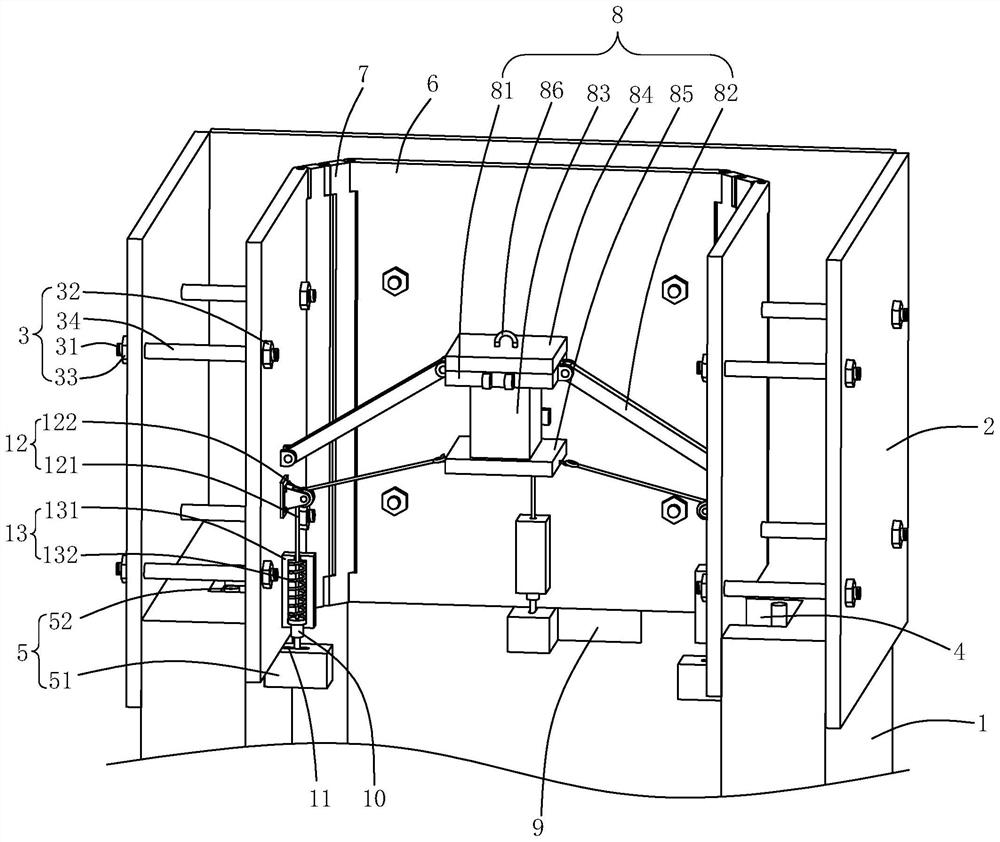

[0036] The following is attached Figure 1-3 The application is described in further detail.

[0037] The embodiment of the present application discloses a construction method for a cast-in-situ bridge pier of a municipal viaduct. It includes the following steps:

[0038] S1. Pier construction.

[0039] S2, pier body construction. It includes the following steps:

[0040] S21. Construction of the first pier section 1: according to the design thickness of the pier body, arrange a circle of steel skeletons (not shown in the figure) on the pier seat, and then arrange the hydraulic self-climbing formwork mechanism (not shown in the figure) on Afterwards, place the inner box on the pier, use multiple sets of tension members 3 to tighten the inner box and the outer formwork 2 on the hydraulic self-climbing formwork, and then move to the space formed by the inner box and the outer formwork 2. Concrete is poured into the cavity and compacted. Wherein, the number of groups of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap