High-sensitivity large-flow water flow sensor

A water flow sensor, high-flow technology, used in liquid/fluid solid measurement, volume/mass flow generated by electromagnetic effects, instruments, etc., can solve problems such as slow flow rate, small flow rate of water flow sensor, and long waiting time for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

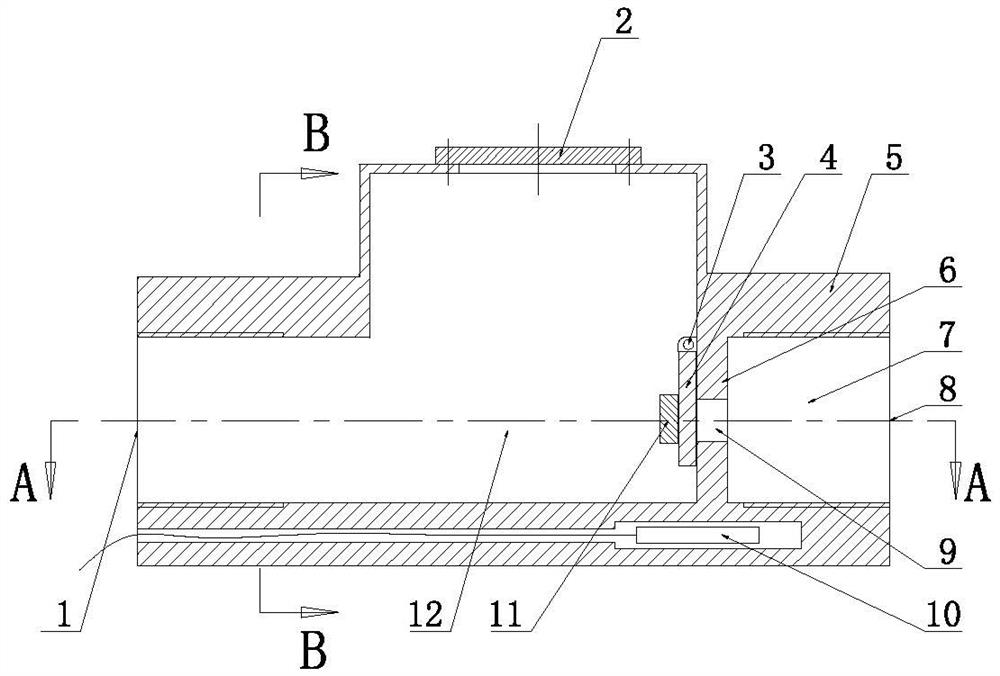

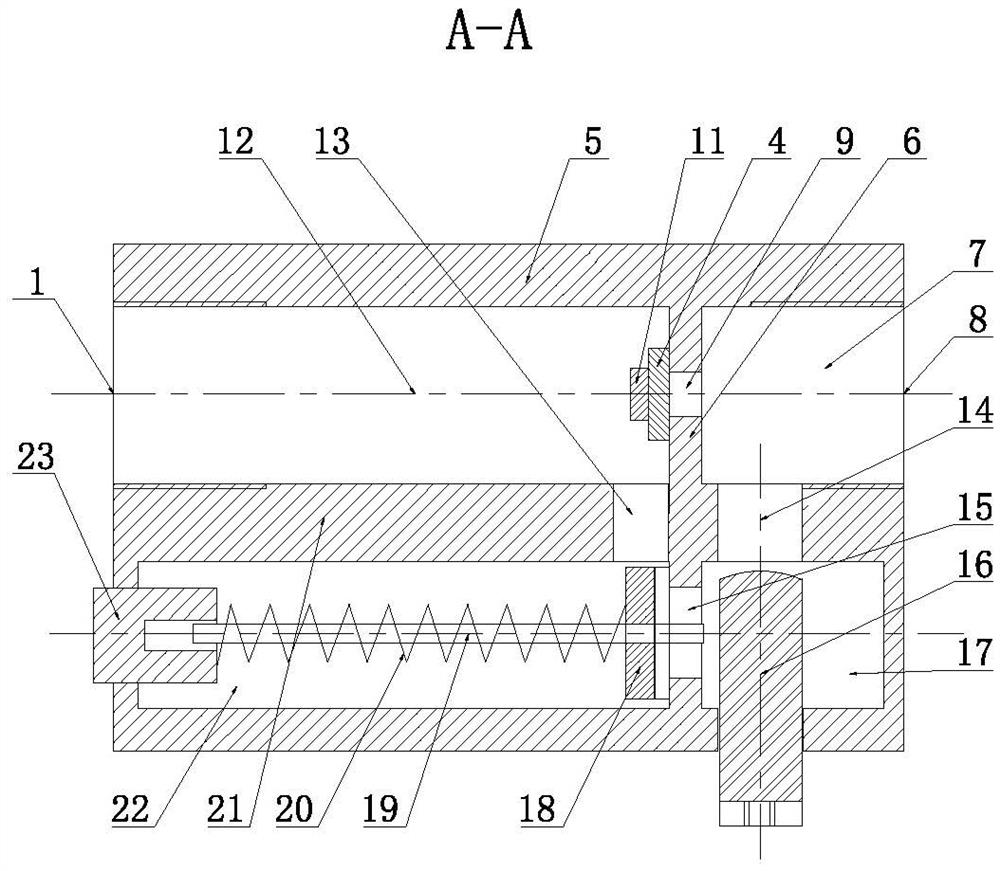

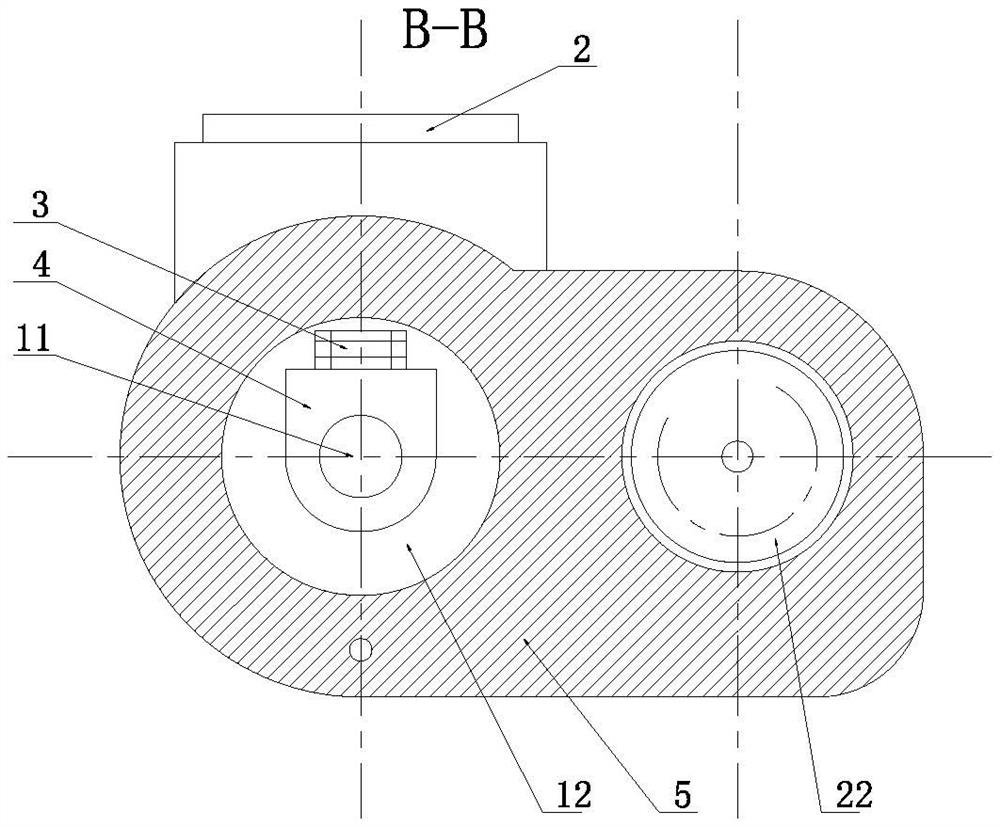

[0018] like Figure 1-3 As shown, it is a high-sensitivity and large-flow water flow sensor, which includes a hollow housing 5, a water inlet 8 is provided on one side of the housing 5, and a water outlet 1 is provided on the other side. Partition plate 6 and transverse partition plate 21, longitudinal partition plate 6 and transverse partition plate 21 divide housing 5 into four chambers, which are respectively the first water chamber 7, the second water chamber 12, the third water chamber 17 and the first water chamber. Four water chambers 22, a first flow hole 9 and a second flow hole 15 are provided on the longitudinal partition 6, a third flow hole 14 and a fourth flow hole 13 are provided on the transverse partition 21, the first water flow The cavity 7 is directly connected to the water inlet 8, the second water cavity 12 is connected to the water outlet 1, the first water cavity 7 and the second water cavity 12 are connected through the first flow hole 9, and the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com