Annular steel wire winding equipment for steel cylinder concrete pipeline

A technology for steel cylinders and pipes, applied in the field of concrete pipes, can solve the problems of reduced steel wire continuity, weak wire winding, easy loosening, etc., and achieve the effects of improving continuity, avoiding breakpoints, and avoiding loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

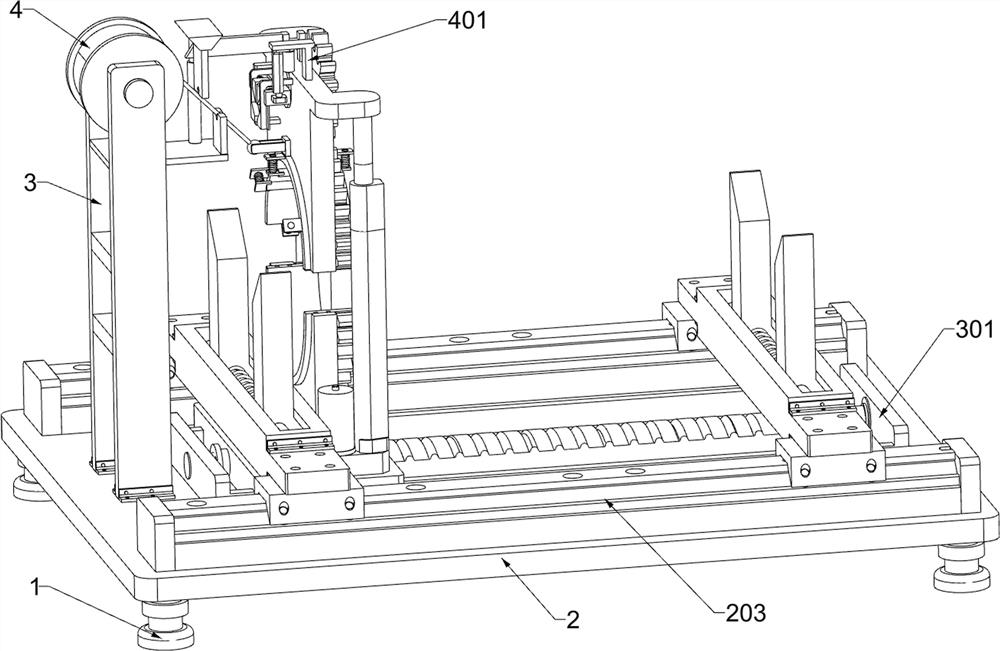

[0029] A steel cylinder concrete pipeline hoop-type winding steel wire equipment, according to Figure 1-2 As shown, it includes a support foot 1, a load bearing plate 2, a first fixed frame 3, a wire wheel 4, a limit unit and a wire winding unit; the upper part of the four support feet 1 is fixedly connected with a load bearing plate 2; The first fixed frame 3 is connected; the upper part of the first fixed frame 3 is equipped with a wire wheel 4; the upper surface of the load bearing plate 2 is connected with the limit unit; the middle part of the upper surface of the load bearing plate 2 is connected with a wire winding unit; .

[0030] When working, the staff will move the load-bearing plate 2 to the position to be used, and keep the four feet 1 level, and then the staff will place the steel cylinder concrete tube core in the limit unit, and pass through the limit unit Limit the steel cylinder concrete tube core, place the steel wire used in the wire pulley 4 on the first...

Embodiment 2

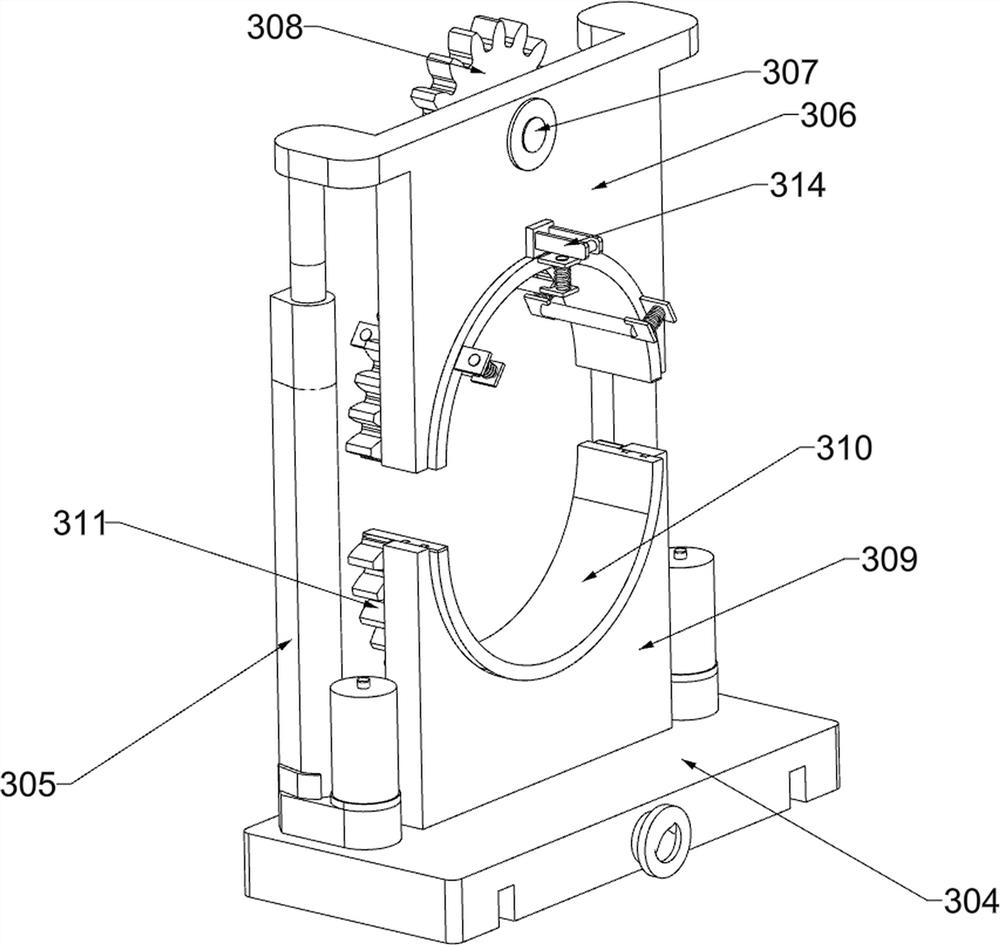

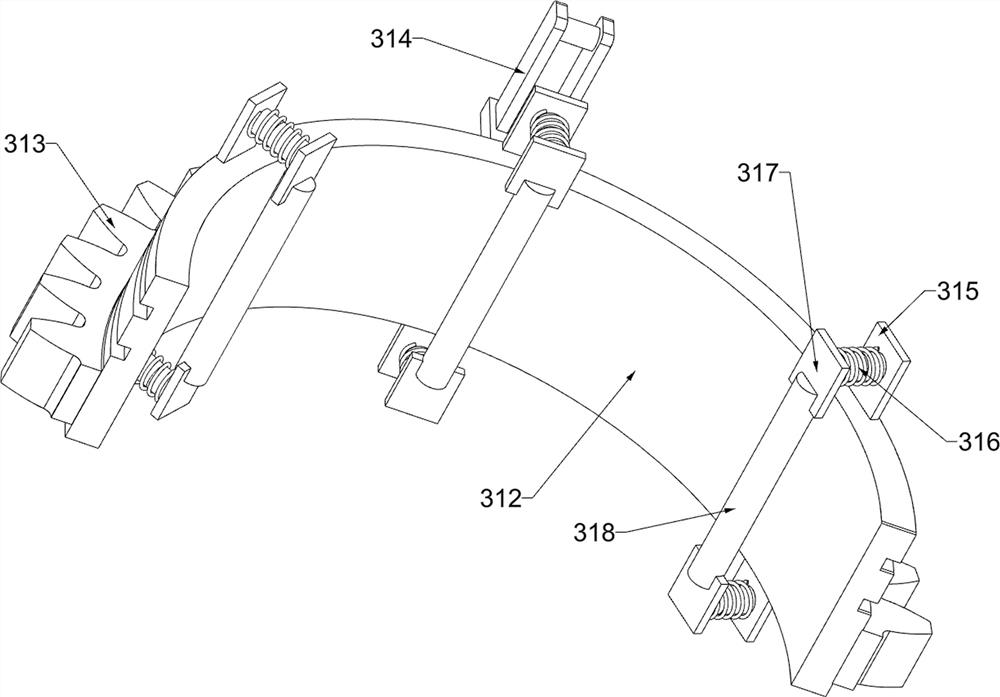

[0032] On the basis of Example 1, according to figure 1 and Figure 3-8As shown, the limit unit includes a first fixed plate 201, a second fixed plate 202, a first guide rail 203, a first electric slider 204, a second guide rail 205, a second electric slider 206, a second fixed frame 207, The first connecting rod 208, the first limiting plate 209 and the first spring 210; two first fixed plates 201 are affixed to the front of the upper surface of the bearing plate 2; two second fixing plates are affixed to the rear of the upper surface of the bearing plate 2 A fixed plate 202; a first guide rail 203 is fixedly connected between the two first fixed plates 201; two first electric sliders 204 are slidably connected to the upper part of the first guide rail 203; There is a second guide rail 205; the upper part of the second guide rail 205 is slidingly connected with two second electric sliders 206; the upper part between the first electric slider 204 and the second electric slide...

Embodiment 3

[0041] On the basis of Example 2, according to figure 1 and Figure 9-11 As shown, a cutting unit is also included; the upper part of the winding unit is connected with a cutting unit; the cutting unit includes a third fixed block 401, a second electric push rod 402, a sliding frame 403, a third fixed frame 404, and a first wedge plate 405 , the second wedge-shaped plate 406, the round rod 407, the cutter 408 and the second spring 409; the upper surface of the first arc-shaped plate 306 is fixedly connected with the third fixed block 401; the third fixed block 401 bottom bolt is connected with the second electric pusher Rod 402; the telescoping part of the second electric push rod 402 is fixedly connected with a sliding frame 403; the upper part of the first arc-shaped plate 306 and is located below the third fixed block 401 is fixedly connected with a third fixed frame 404; the sliding frame 403 and the third fixed The frame 404 is slidingly connected; the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com