Smokeless furnace outer barrel welding equipment and welding method thereof

A technology for welding equipment and an outer cylinder is applied in the field of welding equipment for the outer cylinder of a smokeless furnace and its welding field, which can solve the problems of reducing the work efficiency of welders, and achieve the effects of improving convenience, reducing the possibility of being too dazzling, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The following is attached Figure 1-10 The application is described in further detail.

[0061] The embodiment of the present application discloses a smokeless furnace outer cylinder welding equipment.

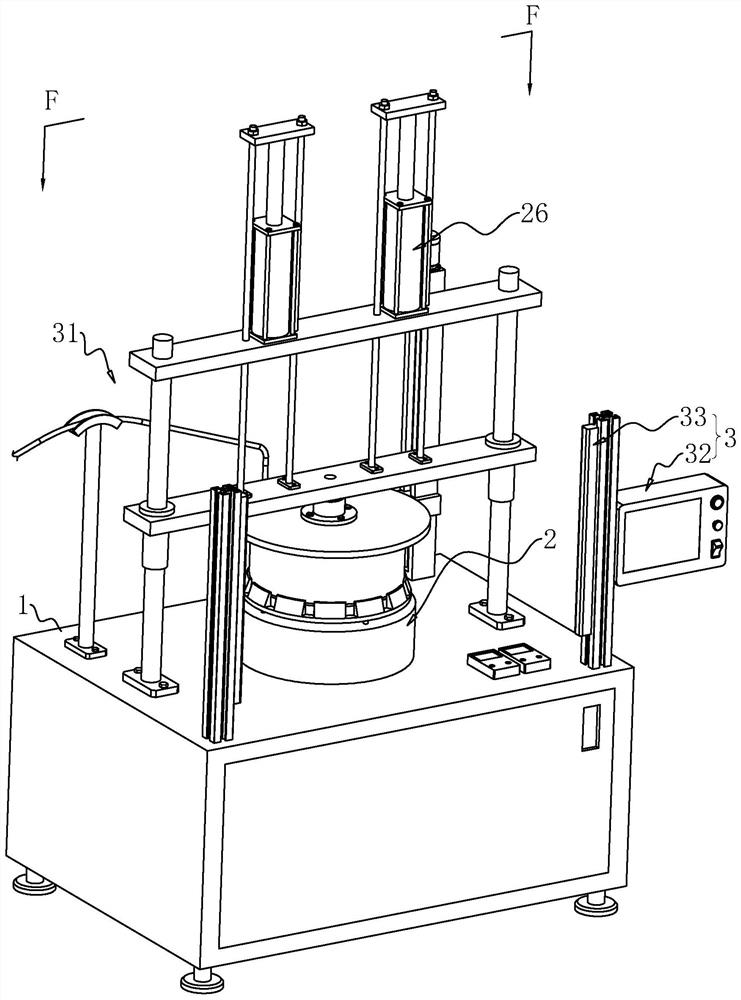

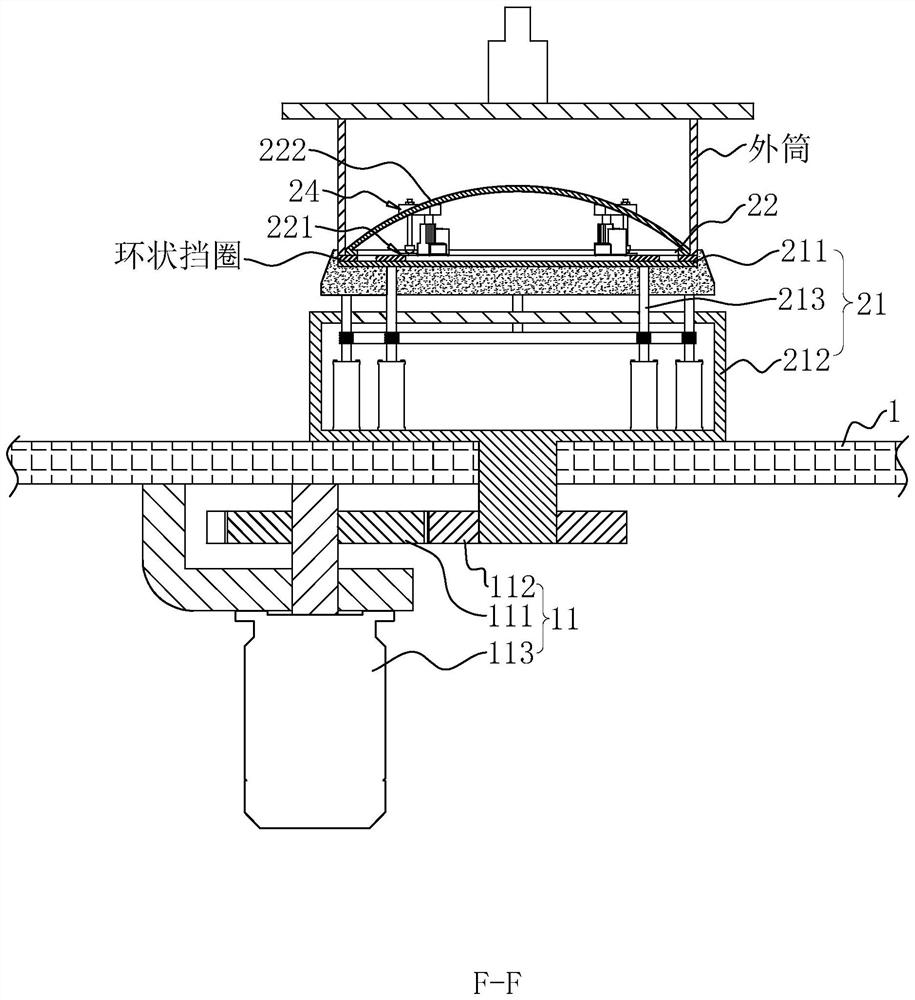

[0062] refer to figure 1 with figure 2 , a smokeless furnace outer cylinder welding equipment includes a frame 1, a fixing mechanism 2 and a welding mechanism 3, wherein a driving member 11 is installed in the frame 1, and the fixing mechanism 2 is rotatably connected to the frame 1, and the driving member 11 is used for Drive the fixing mechanism 2 to rotate; the welding mechanism 3 is used to perform welding actions, including spot welding and full welding; the driving part 11 and the welding mechanism 3 are connected in communication and can be opened and closed synchronously.

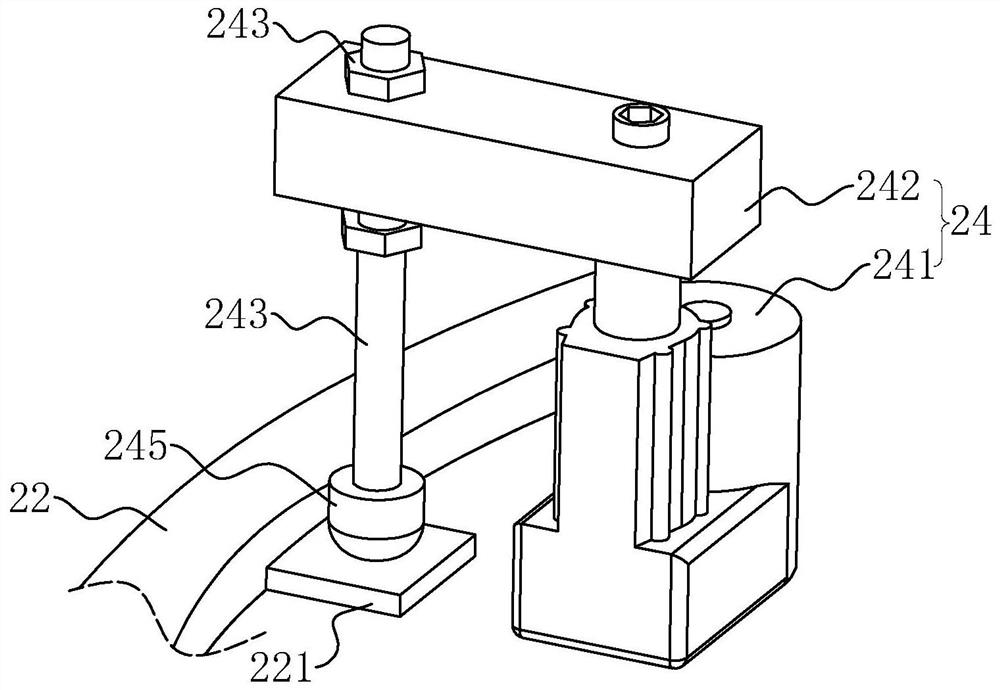

[0063] refer to figure 2 with image 3 The fixing mechanism 2 includes an abutment platform 21 rotatably connected to the frame 1 and a positioning ring 22 detachably connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com