Quality inspection equipment for bottom of bridge and implementation method of quality inspection equipment

A bridge and equipment technology, applied in the field of quality inspection equipment at the bottom of the bridge, can solve the problems of long detection time, high risk factor, difficulty in comprehensive detection, and troublesome detection of the bottom of the bridge, so as to eliminate hidden dangers of bridge problems and avoid electric lifting poles damage, detection part clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] In order to better demonstrate the implementation process of the quality inspection at the bottom of the bridge, this embodiment now proposes an implementation method for the quality inspection equipment at the bottom of the bridge, including the following steps:

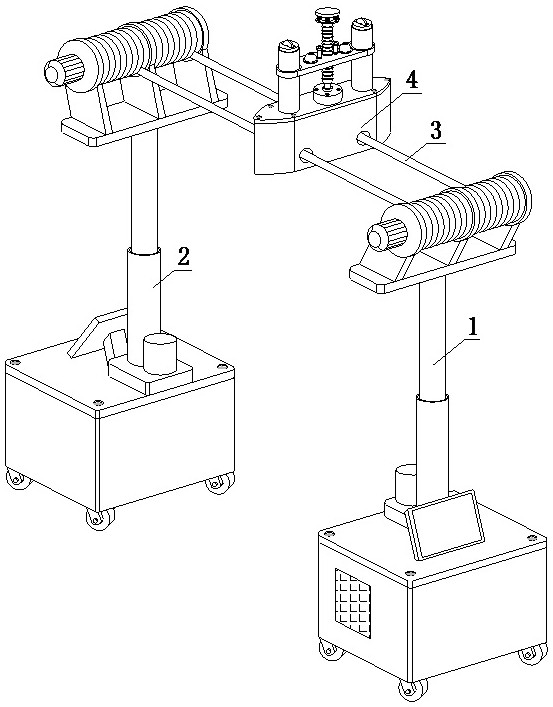

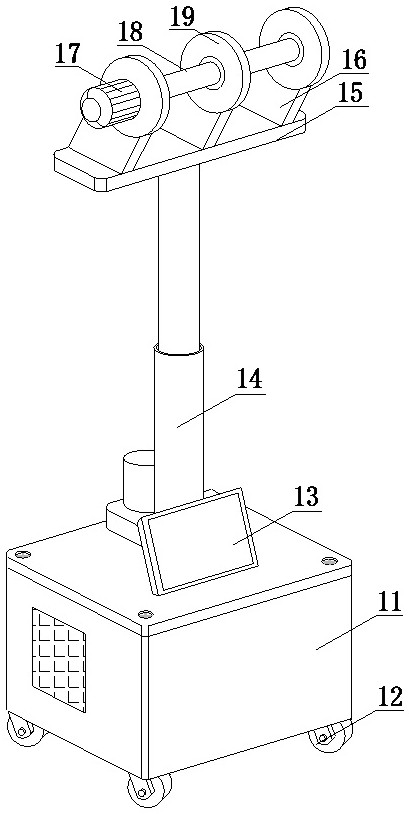

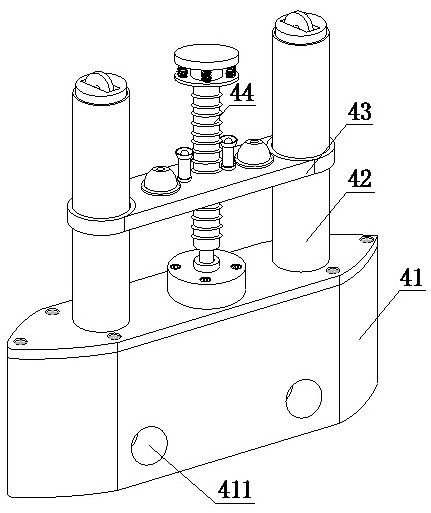

[0046] Step 1: Put the first observation control mechanism 1 and the second observation control mechanism 2 on the guardrails of two adjacent bridge piers respectively, and the two conductive ropes 3 at the upper end of the first observation control mechanism 1 pass through the detection mechanism 4 respectively, Pull the conduction rope 3 to the second observation control mechanism 2 from the bridge again, and wind the conduction rope 3 outside the rotating rod 18 on the second observation control mechanism 2 upper ends;

[0047] Step 2: the first motor 17 of the first observation control mechanism 1 and the second observation control mechanism 2 rotate in reverse direction at the same time, until the conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com