Laser high-pressure water rocket crusher and working method thereof

A crusher, high-pressure water technology, used in laser welding equipment, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of people being smashed and injured, and the path is uncertain, so as to reduce the number of operators, ensure safety, and achieve ore mining. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

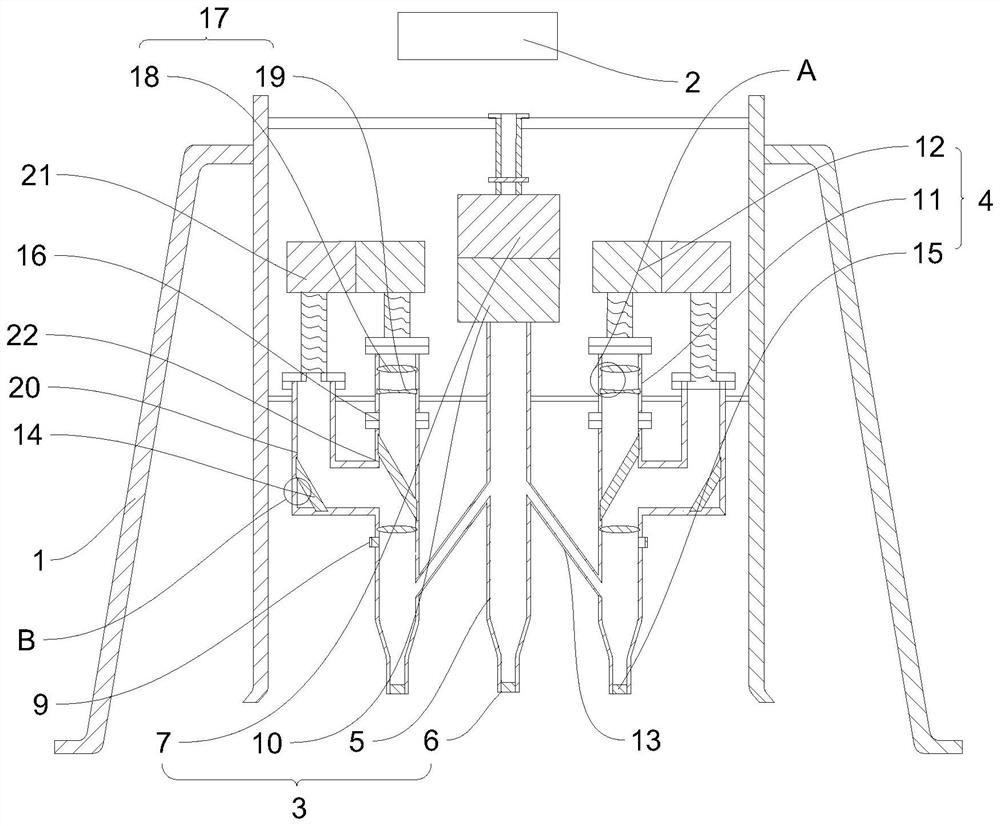

[0045] Please refer to Figure 1-Figure 3 , the purpose of the present invention is to provide a laser high-pressure water arrow breaker and its working method, which can reduce labor costs and processing procedures, thereby reducing the probability of personnel injuries in landslide accidents, and at the same time, the reduction of labor costs and processes is also indirectly Increased mining profitability.

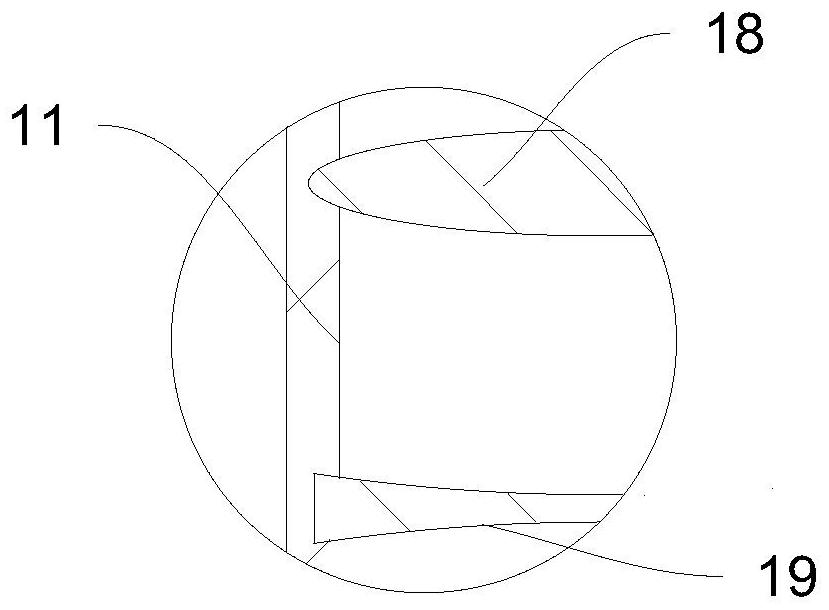

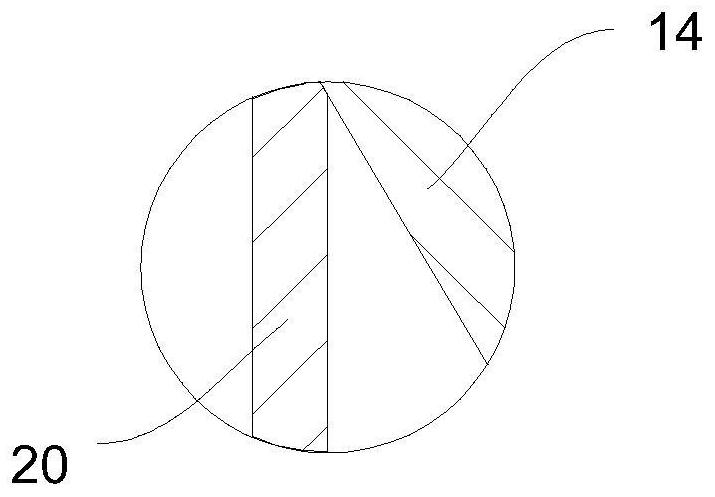

[0046] A laser high-pressure water arrow breaker and its working method, comprising a breaker main body 1 and a central processing unit 2, the above-mentioned breaker main body 1 is provided with a high-pressure water cutting assembly 3 and a laser cutting assembly 4, the above-mentioned high-pressure water cutting assembly 3 and the above-mentioned The laser cutting components 4 are all electrically connected to the above-mentioned central processing unit 2 .

[0047] The principle of the present invention: in the traditional mining process, the crusher needs to use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com