A general pre-embedded device for pc components

A pre-embedded device and component technology, which is applied in the direction of ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems that affect the normal installation of prefabricated wall panels, the inclination of the end of embedded parts, and the offset of pads, etc. The effect of long operation time, improved connection strength, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

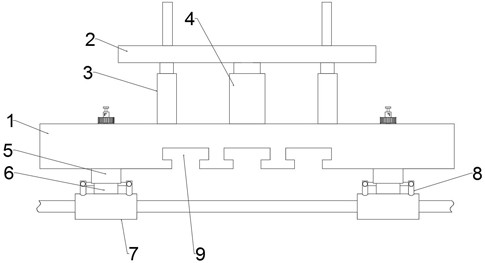

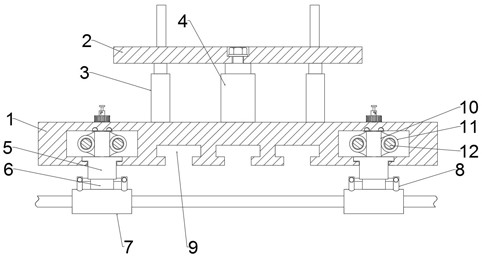

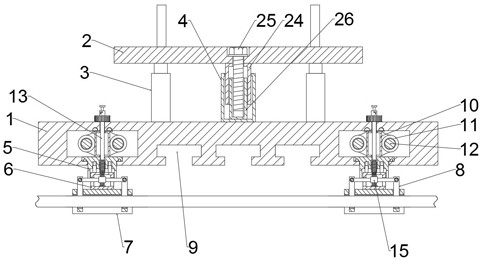

[0024] Example: see Figure 1-5 , a general pre-embedded device for PC components, comprising a base plate 1, a fitting plate 2 horizontally arranged above the base plate 1, and telescopic rods 3 fixed to the four corners of the bottom surface of the fitting plate 2 and the base plate 1, and the middle part of the top surface of the base plate 1 is vertically A connecting column 4 is provided, and a fine-tuning assembly for adjusting the distance between the base plate 1 and the fitting plate 2 is provided in the connecting column 4; a number of T-shaped fitting grooves 9 are longitudinally opened in the middle of the bottom surface of the base plate 1, so that the poured concrete can be condensed in the fitting The inside of the groove 9 improves the connection area and connection strength between the base plate 1 and the beam body; both sides of the base plate 1 are longitudinally provided with installation cavities, the bottom of the installation cavity is vertically provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com