Improved typesetting conveying device with monitoring function

A conveying device and improved technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of large cost and required space, monitoring whether the shape of software objects changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

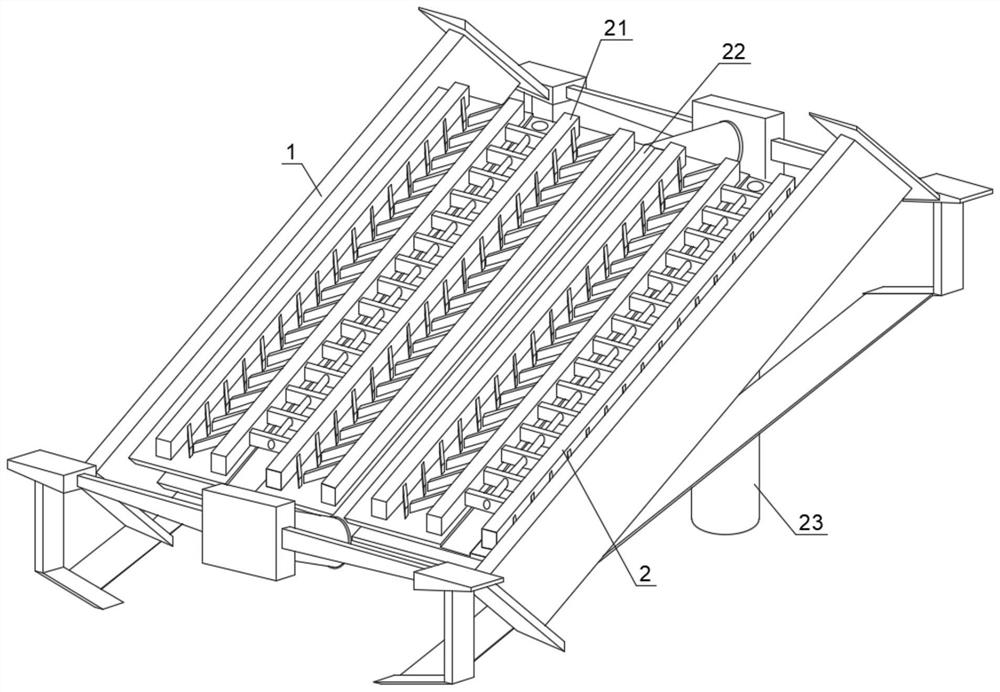

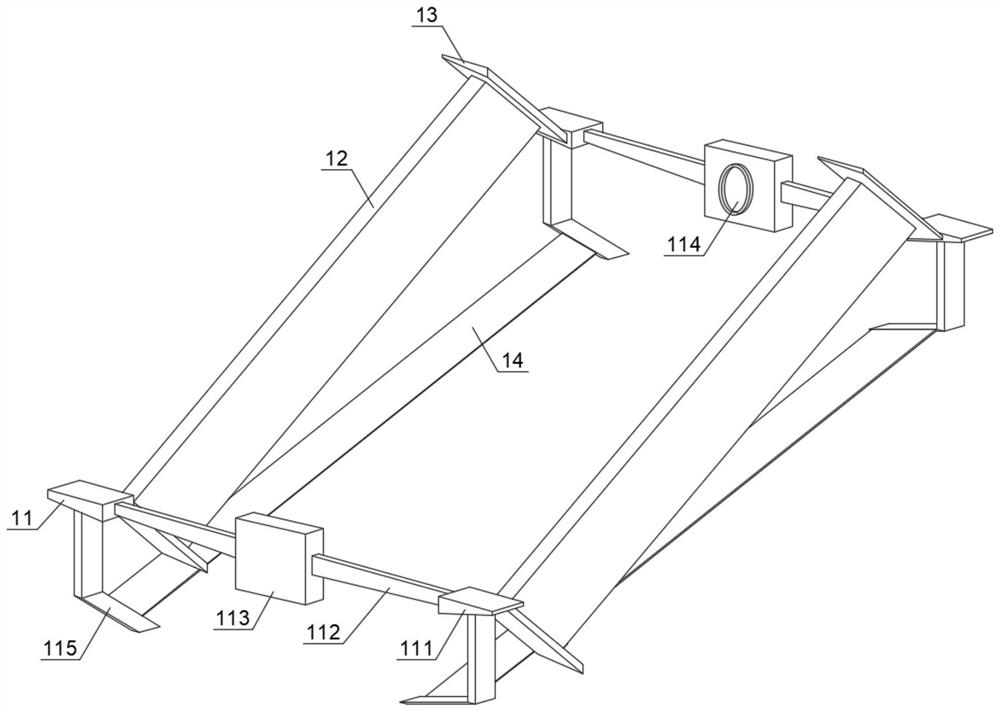

[0032]An improved typesetting conveying device with monitoring function, comprising a typesetting mechanism 1 and a conveying mechanism 2, the inner cavity of the typesetting mechanism 1 is equipped with the conveying mechanism 2, and the typesetting mechanism 1 includes a first support frame 11, an arrangement installation bar 12, a second Support frame 13 and slideway 14, the side end of the first support frame 11 is movably connected with the second support frame 13 by arranging installation bar 12, and the lower end of the first support frame 11 and the second support frame 13 connects slideway 14, the first Support frame 11 comprises installation block 111, support bar 112, support block 113, penetration hole 114 and support post 115, the inner end of installation block 111 is installed support bar 112, is connected by support block 113 between support bar 112, and support block 113 The side end face of the side end offers penetration hole 114, and the bottom end of instal...

Embodiment 2

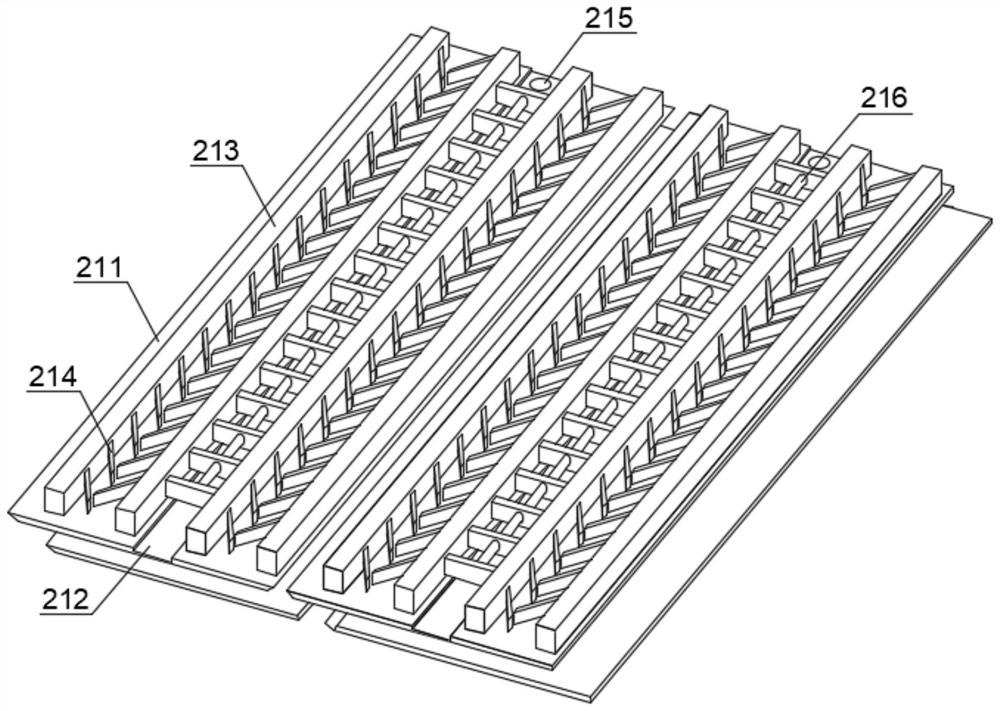

[0034] The inflatable mechanism 2141 includes an inflatable board 21411, transparent holes 21412, connecting strips 21413 and load-bearing movable rods 21414. The side walls of the inflatable board 21411 are provided with transparent opening holes 21412, and the two ends of the inflatable board 21411 pass through the connecting strips. 21413 is movably connected with the load-bearing movable rod 21414, and the conveying plate 21 also includes an inflatable vertical cylinder 216, which penetrates through the inner cavity of the opening hole 21412, so that the inflatable mechanism 2141 and the inflatable vertical cylinder 216 become a whole, and run through the pipe 22 The two ends are connected in series with the inner cavity of the penetration hole 114 respectively. The penetration tube 22 is a member made of a synthetic rubber material. The maximum stretching length of the penetration tube 22 is not greater than the length of the plate body 211. It fits with the top of the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com