Liquid crystal display module and backlight module thereof

A liquid crystal display module and backlight module technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of poor protection, weak anti-vibration performance, etc., and achieve the effect of good vibration reduction and buffering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

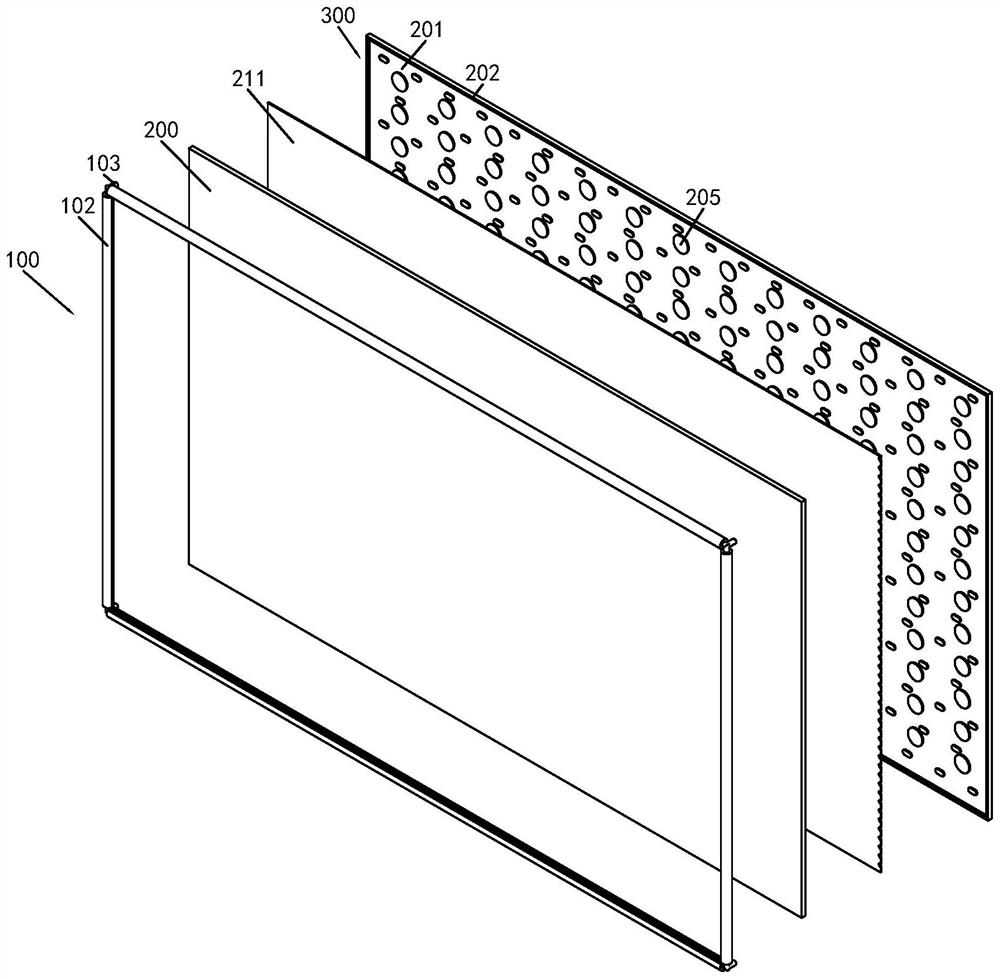

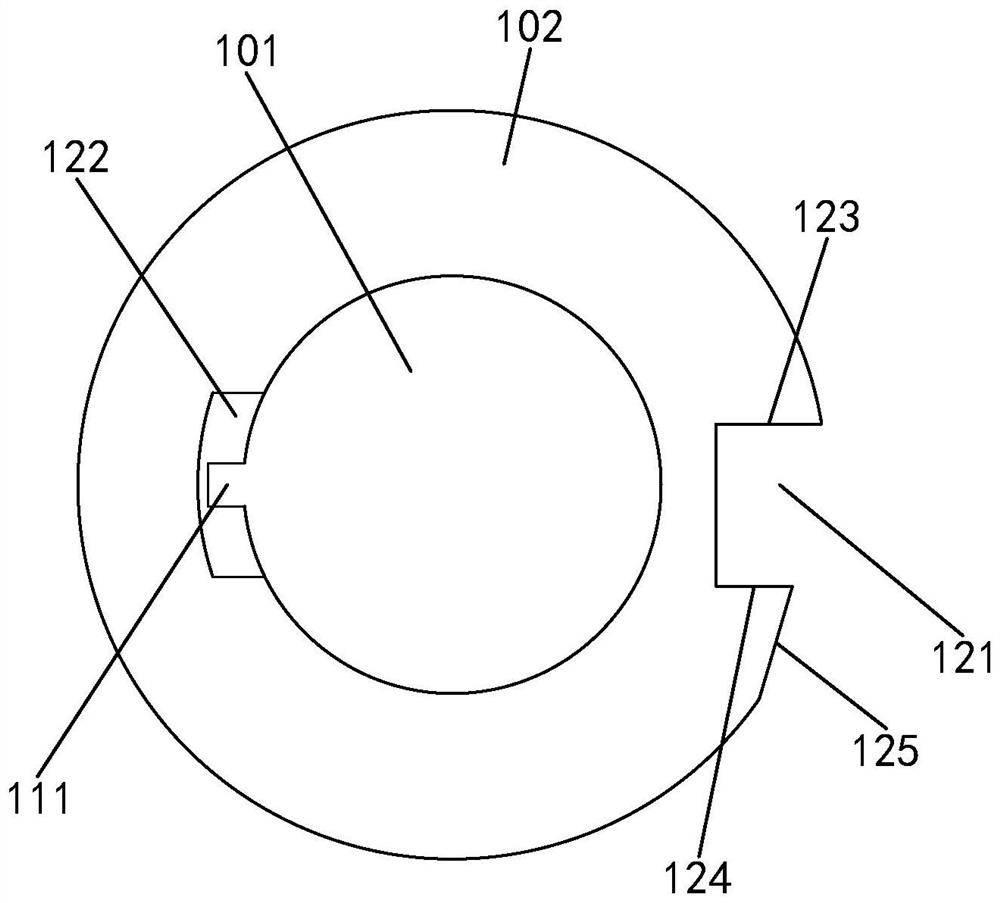

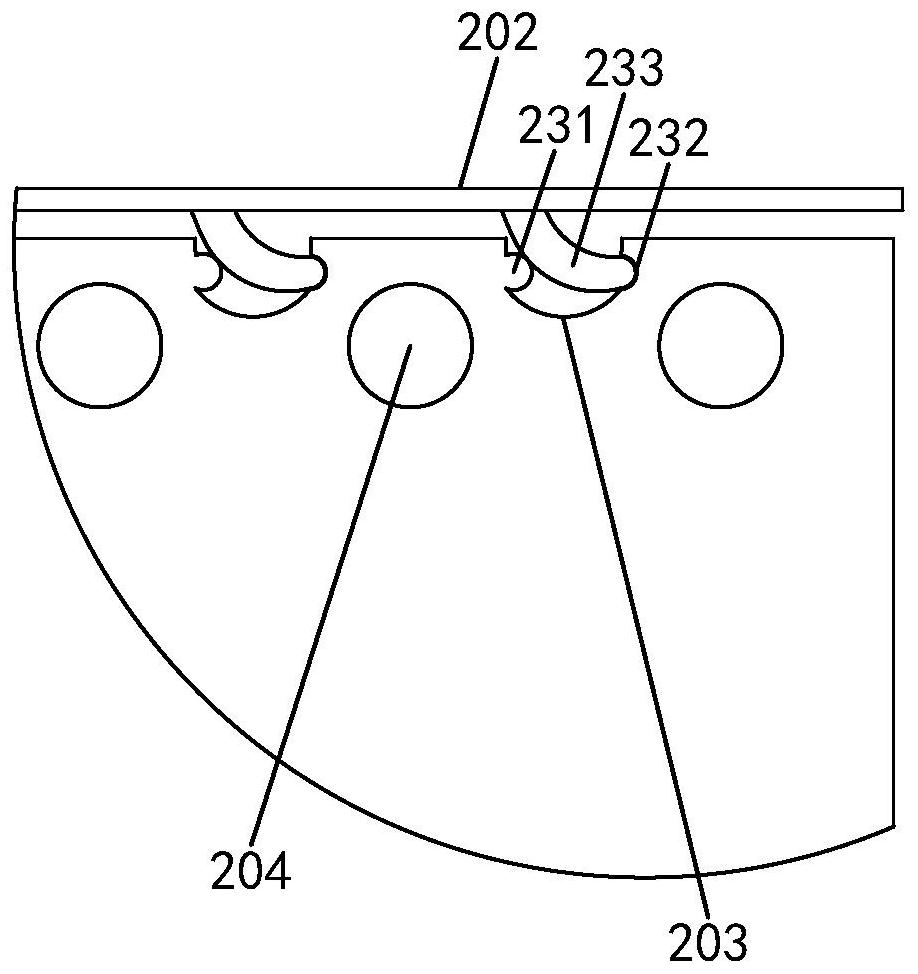

[0019] Example: see Figure 1-4 , a liquid crystal display module, including a front frame 100, a display panel 200 and a backlight module 300, the front frame 100 includes a support frame 101, the support frame 101 is rectangular, each side of the support frame 101 The rotating sleeve is provided with an elastic support sleeve 102, and the elastic support sleeve 102 is made of fluororubber as a whole, which has good elasticity;

[0020] The elastic support sleeve 102 is provided with a slot 121 along its length direction that fits into the edge of the display panel 200 , and the four side edges of the display panel 200 are respectively snapped into the slots located in the circumferential direction of the elastic support sleeve 102 . The groove 121 is connected to the inner wall of the insertion groove 121 through elastic glue, the elastic glue is silica gel, which is used to further improve the stability of the connection between the display panel 200 and the insertion groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com