Battery pack installation structure of rear vibration-isolated pure electric logistics vehicle

A pure electric animal and installation structure technology, applied in the direction of electric power devices, transportation and packaging, shock absorbers, etc., can solve the problem of vibration isolation effect of the battery pack turned forward, and achieve good vibration isolation and energy absorption effect and reasonable utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

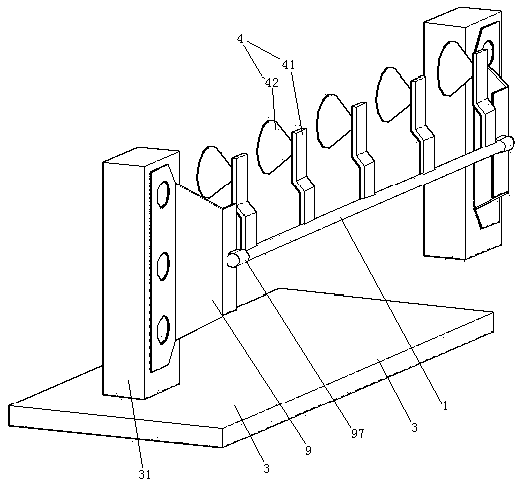

[0040] Embodiment one, see figure 1 , a battery pack installation structure of a rear-mounted vibration-isolation pure electric logistics vehicle, including a car floor 3 and a front bumper 1.

[0041] The car floor 3 is positioned between the front of the trunk behind the car and the rear of the rear seat during use. Both sides of the automobile floor 3 are provided with a connecting column 31 .

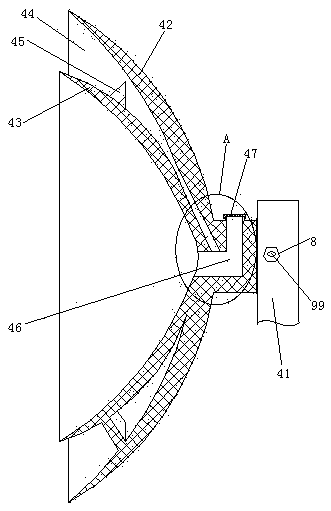

[0042] The front bumper 1 is a tubular structure, specifically a stainless steel tube. The front bumper 1 extends in the width direction of the vehicle. Front bumper 1 is positioned at the rear of the rear row seat of automobile. The front bumper 1 is connected with five battery pack fixing mechanisms 4 . The five battery pack fixing mechanisms 4 are distributed along the length direction of the front bumper 1 , that is, the width direction of the vehicle. The battery pack fixing mechanism 4 includes a connection base 41 and a first suction cup 42 connected to the rear side of t...

Embodiment 2

[0054] Embodiment two, the difference with embodiment one is:

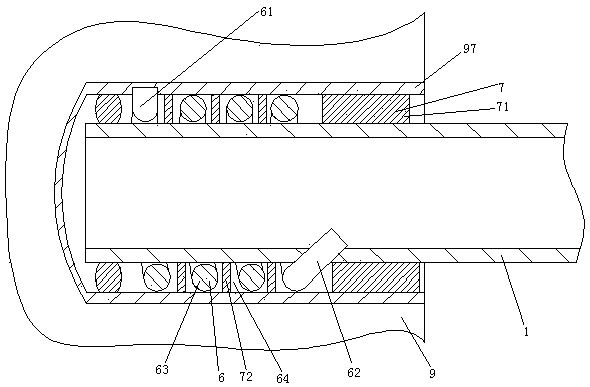

[0055] see Figure 9 , the connecting frame 90 is connected with the heat preservation mechanism 10 . The connecting frame 90 also includes a connecting rod 98 and a damping rod 9 . The connecting rod 98 is an arc-shaped structure that arches upwards (of course, downwards is also possible). One end of the connecting rod 98 is connected with the connecting column 31 . The other end of the connecting rod 98 is connected with one end of the damping rod 9 . The other end sleeve 97 of the damping rod 9 is connected together.

[0056] The heat preservation mechanism 10 includes a box body 100 , a swing rod 107 and a driving motor 108 . The box body 100 is connected with the connecting column 31 . The swing rod 107 is provided with a coating head 1071 . The applicator head 1071 is ring-shaped. The coating head 1071 is sheathed on the connecting rod 98 . The driving motor 108 is fixed on the box body 100 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com