Carrier cleaning process for industrial silkworm breeding

A factory-based, carrier-based technology, applied in cleaning methods using tools, cleaning methods using liquids, chemistry, etc., can solve problems affecting the supply of carriers in silkworm rearing, limit the scale of silkworm rearing, and low cleaning efficiency, and achieve thorough cleaning Carrier, improve cleaning effect, effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

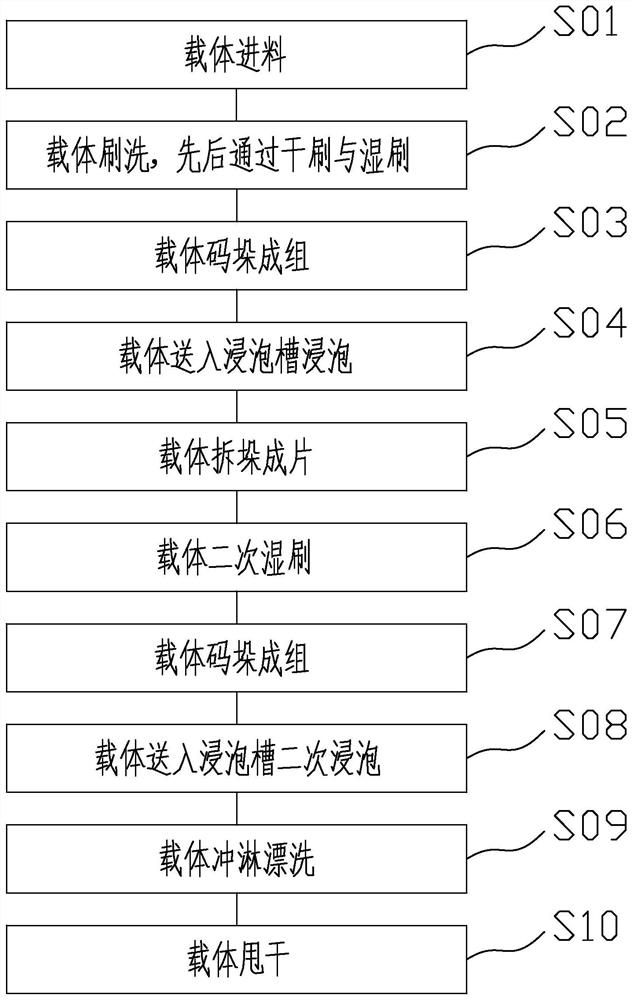

[0050] The present invention aims to provide a carrier cleaning process for industrial sericulture. Aiming at the defects in the existing cleaning technology, a set of systematic cleaning process is designed to realize continuous carrier cleaning in a mechanically automated manner, and the cleaning amount per unit time is greatly increased. increased, significantly improved the cleaning efficiency, and can provide timely and sufficient supply to the sericulture process, providing the basis for large-scale silkworm rearing; and the cleaning process includes brushing, which fully cleans the residual feed and silkworms attached to the surface of the shelf by brushing. Impurities such as sand not only help to improve the cleaning effect of subsequent cleaning processes, such as preventing impurities from mixing into the soaking liquid during soaking and affecting the soaking effect; but also to ensure that the surface of the carrier is clean.

[0051] The following is a detailed de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com