Vertical positioning and fixing method for cargo carrying table

A fixing method and technology of loading platform, applied in the direction of lifting device, lifting frame, etc., can solve the problems of increased drop of loading platform, stretching of lifting chain, vertical height difference, etc. Safe and effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

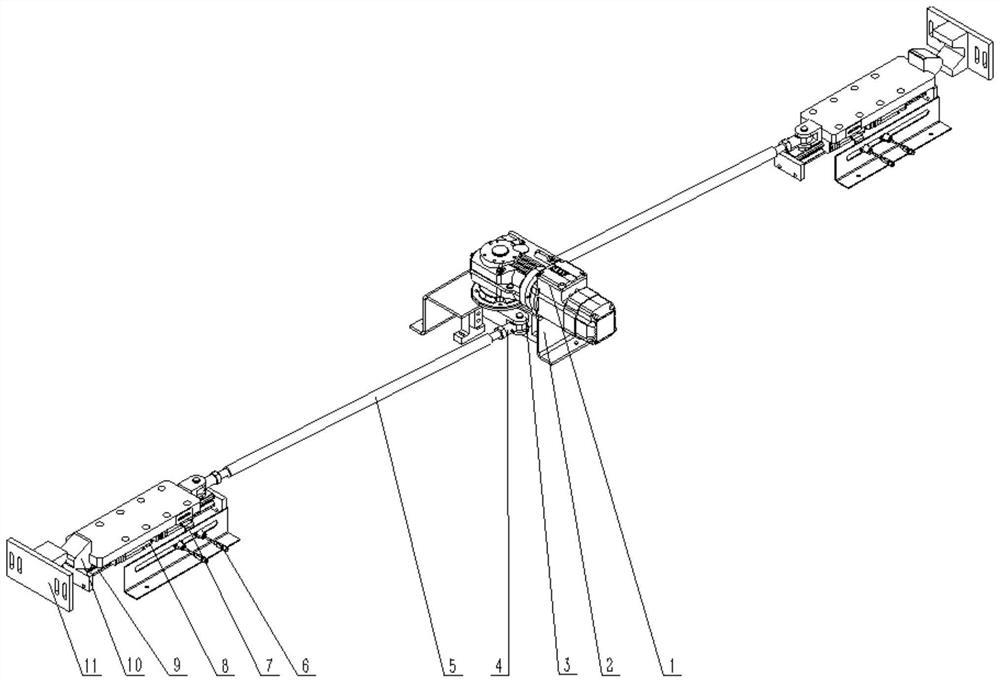

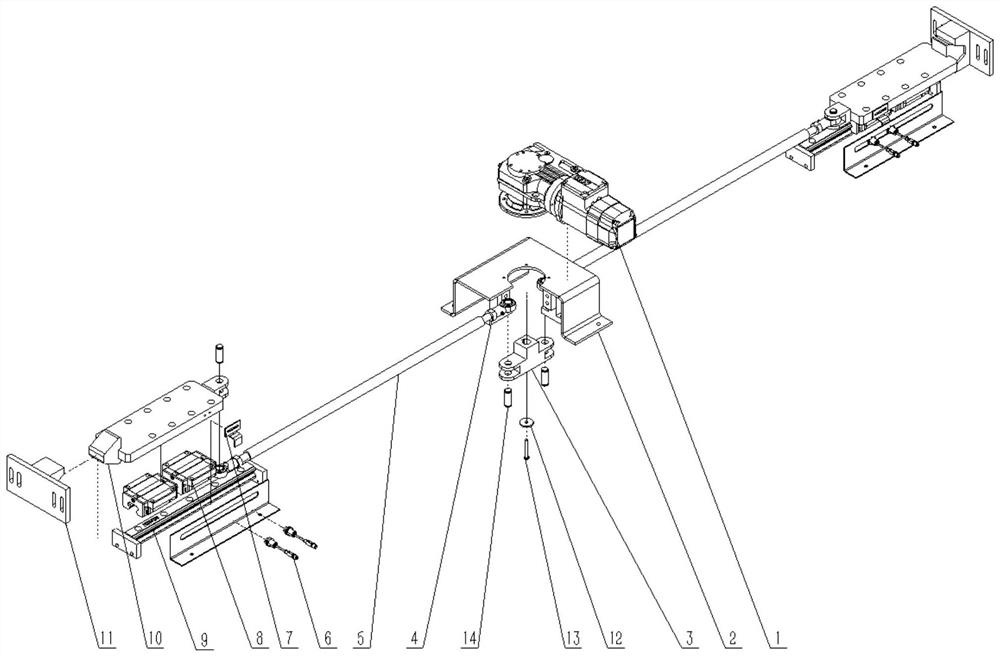

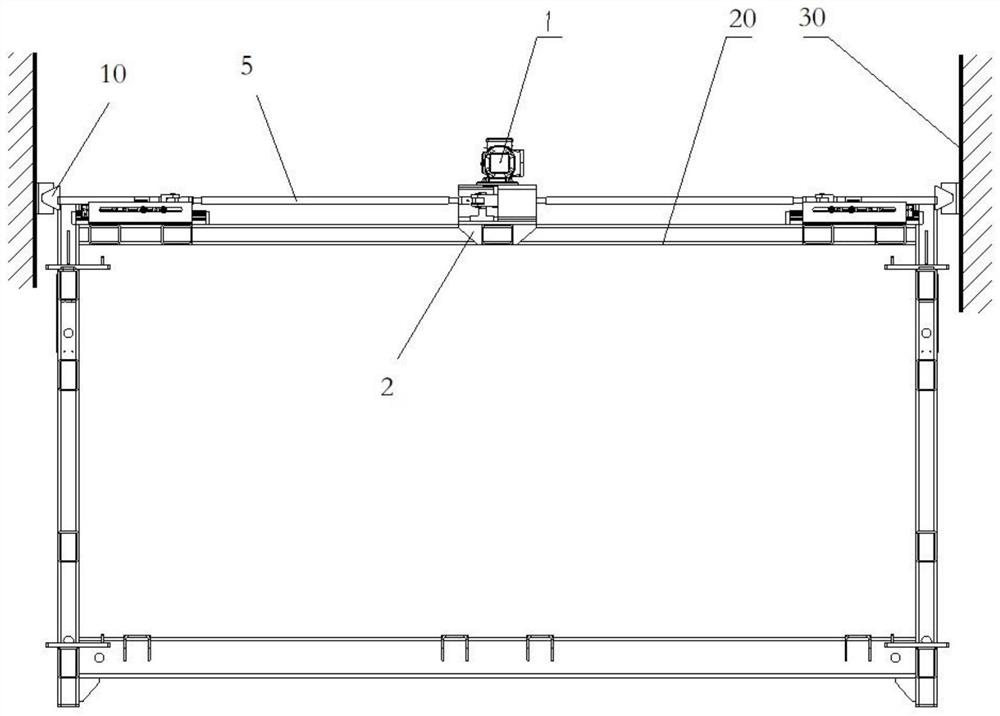

[0020] Example 1, such as Figure 1 to Figure 3 As shown, the vertical positioning and fixing device of the cargo platform applying the method described in this application includes V-shaped positioning grooves 11 installed on both sides of the hoist frame 30 or the wall, the motor support 2 installed on the cargo platform 20 and Two sets of guide rails 9.

[0021] Wherein, the geared motor 1 is fixed on the motor support 2 , and the output shaft of the geared motor 1 is connected to the vertical center of the rotating block 3 through the shaft end gland 12 and the bolt 13 .

[0022] Both ends of the rotating block 3 are symmetrically connected to one end of two sets of connecting rods 5 through a set of pin shafts 14 and fish-eye bearings 4, and the other end of the connecting rod 5 is connected to the V-shaped positioning protrusion through another set of fish-eye bearings 4. The proximal end of the block 10; driven by the geared motor 1, the rotating block 3 rotates around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com