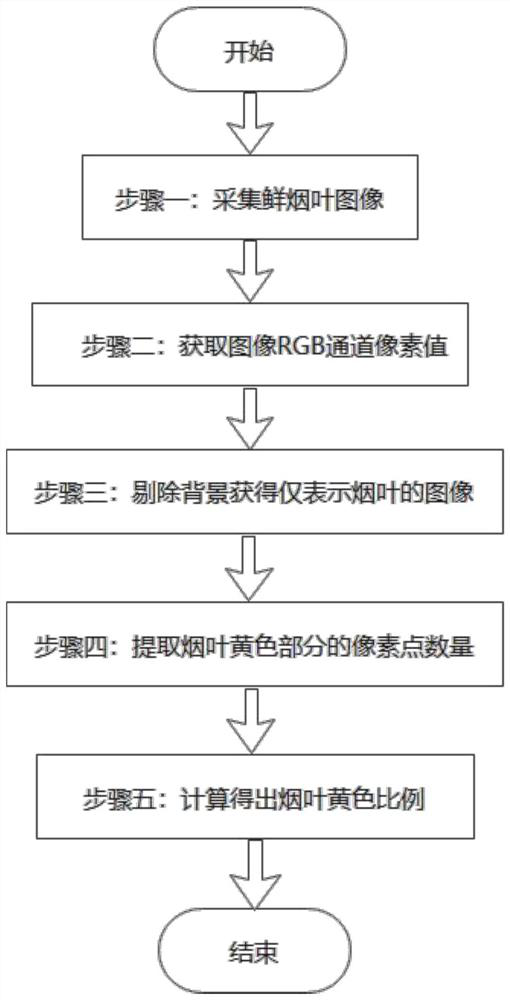

Tobacco leaf primary baking green and yellow ratio extraction method

An extraction method and technology of tobacco leaves, applied in the field of computer machine vision, can solve the problems of relying on manpower, time-consuming and manpower, time-consuming, etc., and achieve the effects of industrial automation, speed-up, and high robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments will specifically illustrate the technical solutions of the present invention in conjunction with the accompanying drawings.

[0021]

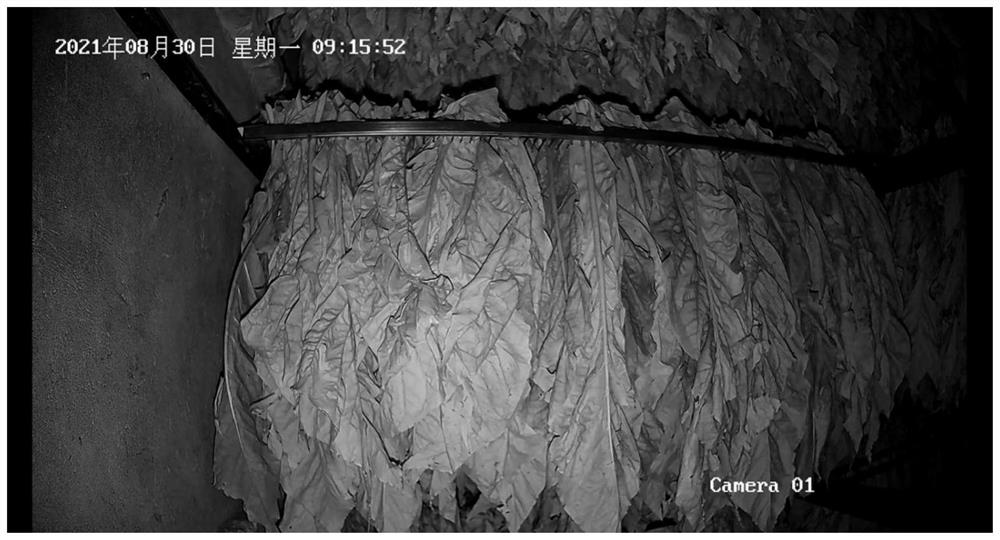

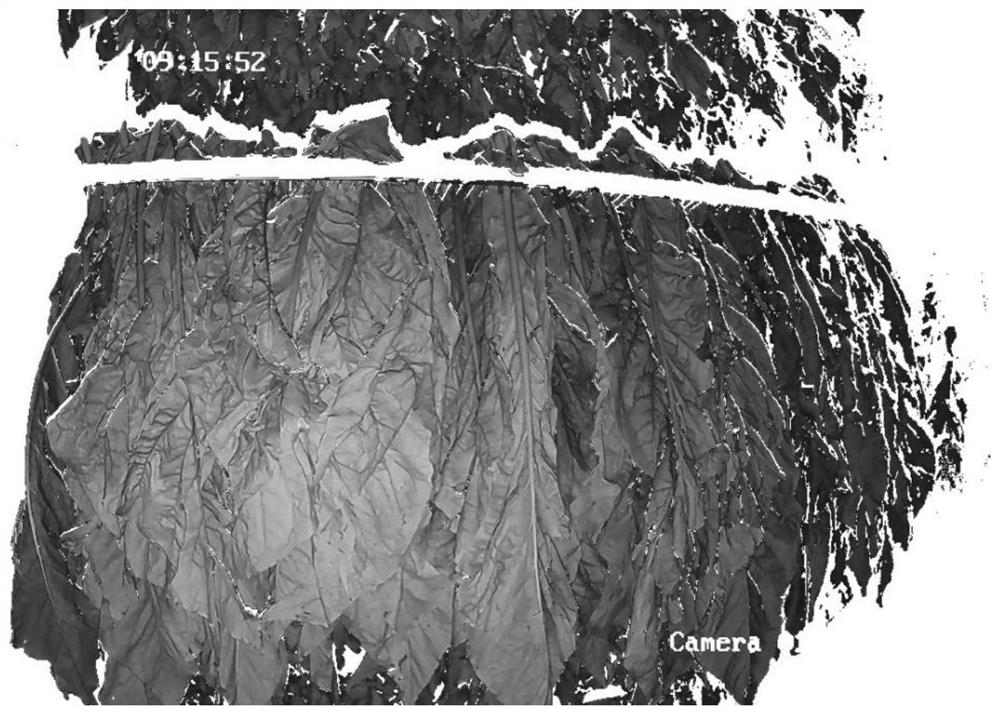

[0022] The present embodiment adopts the fresh tobacco leaves in the baking process as the test object, and the right column is the evaluation of the degree of yellowing of the samples by experts during the baking process, as shown in the following table:

[0023] Table 1 Samples of first-cured fresh tobacco leaves and expert evaluation

[0024] image name Degree of yellowing 08272227 30% yellow or less 08280905 30% yellow or less 08281151 30% yellow or less 08281208 30% yellow or less 08281515 30% yellow or less 08281258 30% yellow or less 08300319 4-5 into yellow 08300542 5-6 into yellow 08300611 5-6 into yellow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com