Self-steering composite wheel

A composite wheel, self-steering technology, applied in the directions of wheels, transportation and packaging, vehicle components, etc., can solve the problems of space occupation and complex steering structure, and achieve the effect of compatibility between steering flexibility and space compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

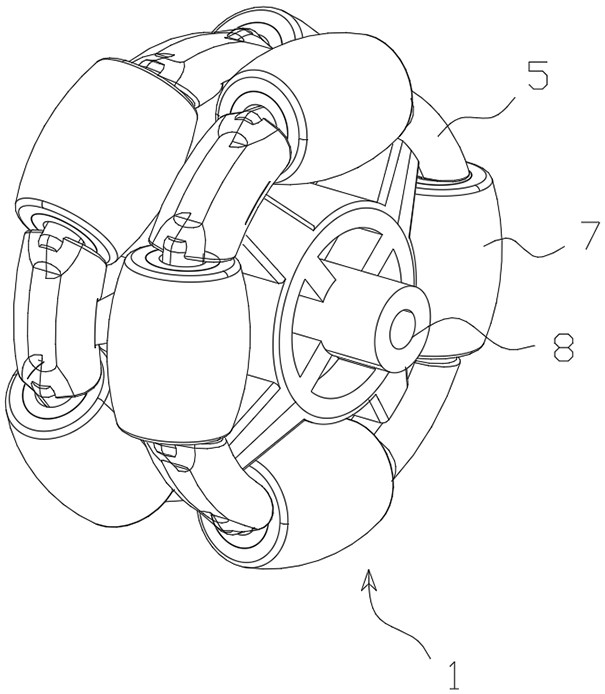

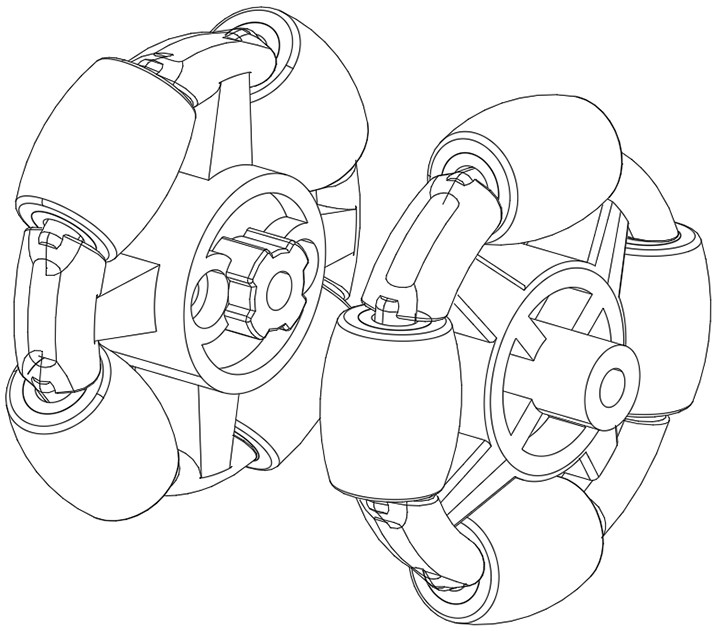

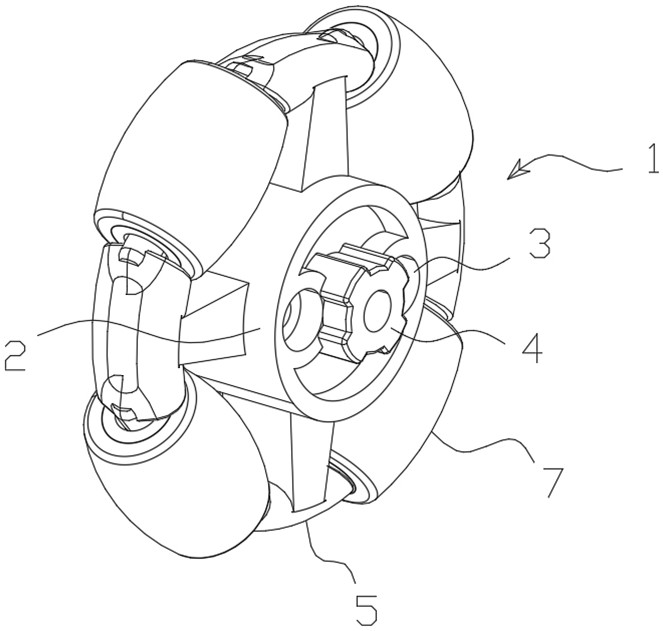

[0039] Combined with the manual Figure 1-Figure 3 The shown self-steering composite wheel includes at least one composite mechanism 1 that forms the self-steering composite wheel, and the composite mechanism 1 includes a support mechanism 2 as the structural skeleton of the self-steering composite wheel and a plurality of runners 7 for steering; At least one end surface of the support mechanism 2 is provided with a travel shaft 8, and a plurality of runners 7 are evenly distributed on the outer peripheral side of the support mechanism 2 with the axis center of the travel shaft 8 as the center of a circle and are located on the same or parallel to each other. In the radial plane of the radial axis 8 , any running wheel 7 is rotatably connected with the supporting mechanism 2 .

[0040] Explanation of structure and principle:

[0041] The compound mechanism 1 is the structural unit that forms the self-steering compound wheel. A self-steering compound wheel can choose one compo...

Embodiment 2

[0045] In order to better adapt to most currently known application scenarios, on the basis of Embodiment 1, this embodiment further combines the Figure 1-Figure 9 The self-steering compound wheel shown is further optimized in structure, as follows:

[0046] In order to better realize the rotation of the runner 7 while satisfying the normal non-steering rotation, preferably, a plurality of arms 5 are distributed on the support mechanism 2 with the axis of travel 8 as the center line, and the two arms of any arm 5 Each end is provided with a steering shaft 6 for mounting the running wheel 7, and the running wheel 7 is rotationally connected with the steering shafts 6 on two adjacent support arms 5.

[0047] In order to improve the stressed state of the runner 7 and at the same time ensure that the runner 7 is in a good rotational connection state, preferably, a sleeve 9 is arranged inside the runner 7, and the two ends of the sleeve 9 are connected to the adjacent image respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com