Front shield tunneling attitude control system

An attitude control, front-mounted technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as excessive deviation, and achieve the effect of improving construction quality and control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

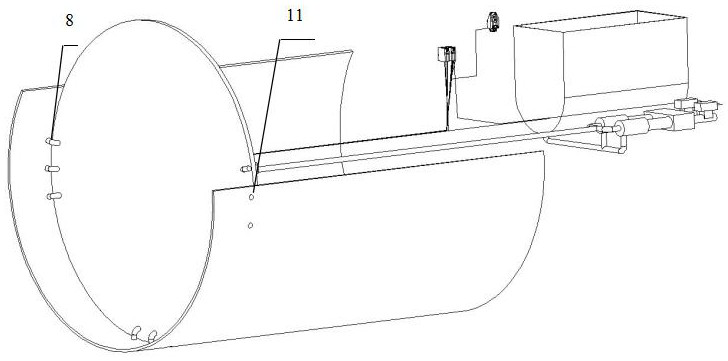

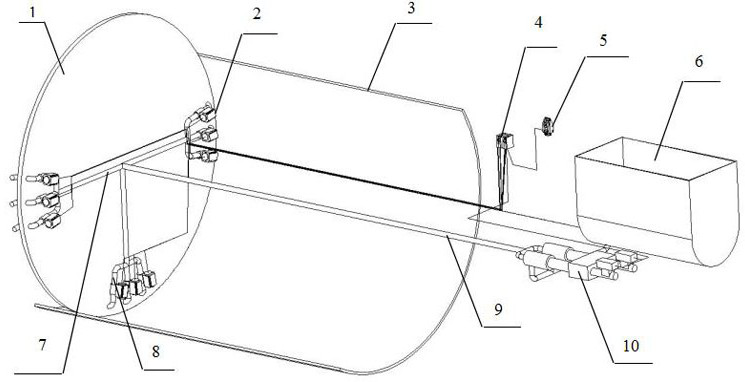

[0019] A front-mounted shield tunneling attitude control system, such as Figure 1 to Figure 2 As shown, it includes an inert slurry storage tank 6 installed on the supporting equipment behind the shield, a grouting pipeline 9 is communicated with the bottom of the inert slurry storage tank 6, and a grouting pipeline 9 is provided near the inert slurry storage tank 6. The grouting pump 10, the other end of the grouting pipe 9 crosses the shield shell 3 and extends to the shield silo partition 1, and the end is connected with a branch pipe 7, and the branch pipe 7 is distributed on the shield silo partition 1 , and the end of the branch pipe 7 is located at the edge of the shield silo partition 1 and is connected with a slurry outlet pipe 8, and the slurry outlet 8 is respectively located at the left and right ends and the bottom of the shield silo partition 1, There are multiple branch pipes 7 and slurry outlet pipes 8 respectively, and they are connected in one-to-one corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com