Automatic grass grid laying machine

An automatic grass and laying machine technology, applied in the field of greening, can solve the problems of unsuitable large-area laying grass squares, a large number of manpower and tools, low efficiency, etc., and achieve the effect of laying hay efficiently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

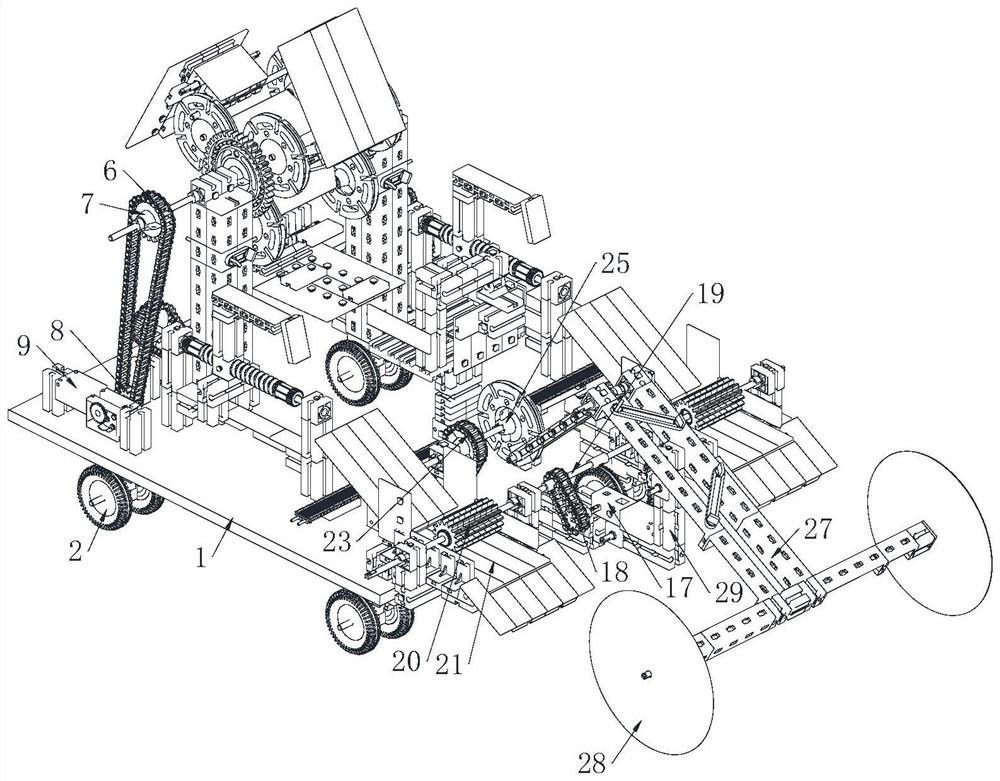

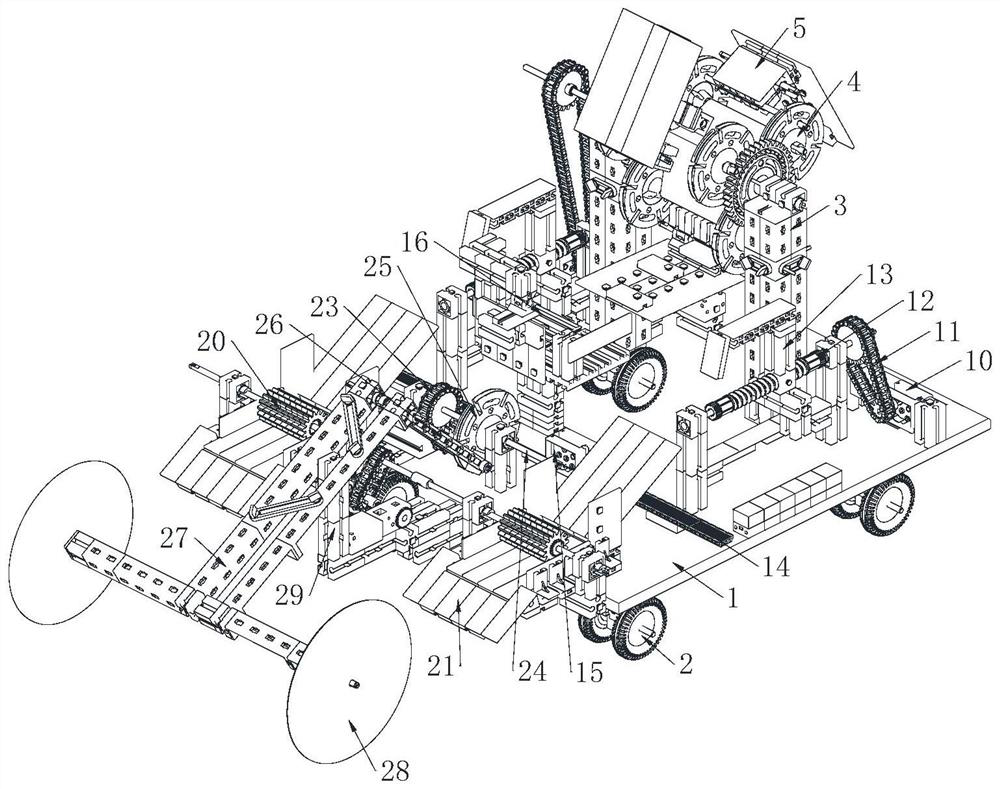

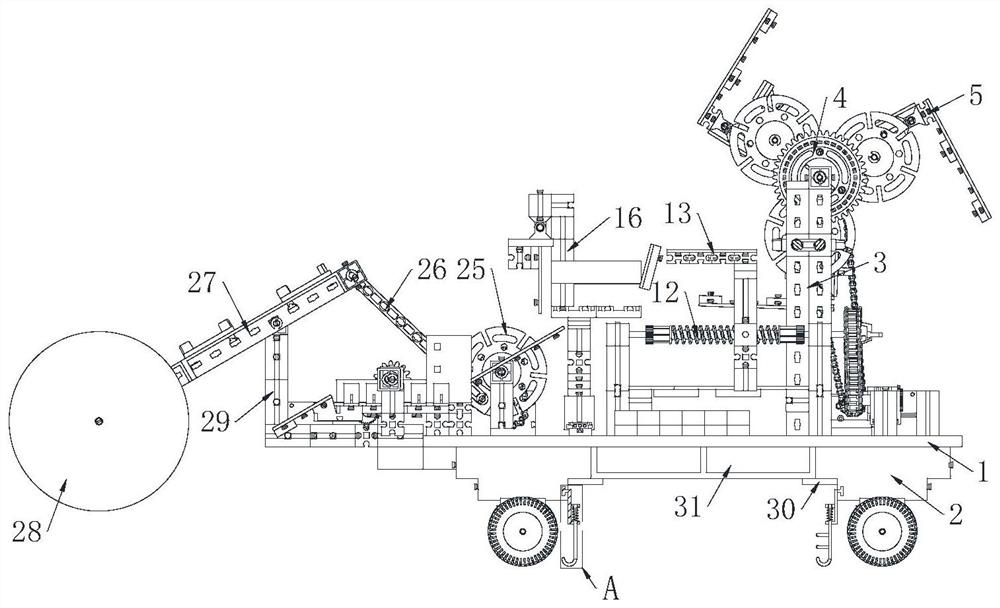

Embodiment 1

[0028] see Figure 1-6 As shown, the automatic grass grid laying machine includes a fixed base plate 1, a power wheel 2, a support frame 3 and a laying unit; the lower surface of the fixed base plate 1 is affixed with a plurality of power wheels 2; The surface is fixed with a support frame 3; the support frame 3 is provided with a laying unit; the laying unit includes a storage rack 4, a tumbleweed cover 5 and a first chain 6; the support frame 3 is rotatably connected with a storage frame 4; the storage rack 4 is rotatably connected with a plurality of tumbleweed covers 5; the storage rack 4 is fixedly connected with a first sprocket 7; the first sprocket 7 is meshed with a first chain 6; the lower end of the first chain 6 is meshed with a second sprocket 8; the second sprocket 8 is affixed to the first reduction motor 9; the upper surface of the fixed bottom plate 1 is symmetrically affixed with a second Geared motor 10; the output shaft of the second geared motor 10 is con...

Embodiment 2

[0037] see Figure 7 As shown in Comparative Example 1, as another embodiment of the present invention, the side of the sliding shaft 33 is fixed with a plurality of pins 36 at vertical intervals; Scraping, so as to realize the function of collecting, so as to realize the function of semi-automatically recovering the hay that has not been fixed, and it is convenient to remove the scraped hay. Cooperating with the sliding shaft 33, it can also move up and down with the sliding shaft 33, so as to adapt to different terrains .

[0038] The working principle is to place the bundled grass rolls in the storage rack 4 and limit them to prevent falling through the rolling grass cover 5, and then drive the first chain 6 and the storage rack 4 to rotate through the first reduction motor 9, thereby realizing the cycle The feeding function, the feeding rack 16 pushes the feeding rack 16 to dock with the storage rack 4 through the push unit 15 made of the combination of the motor and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap