Multi-sealing casing pipe repairing and connecting device

A technology for sealing sleeves and patch joints, which is applied in the direction of engine sealing, wellbore/well parts, engine components, etc. It can solve the problems of restrictions, large outer diameter design, etc., and achieve long working life, good sealing effect and ideal Using Effects and Applying Foreground Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

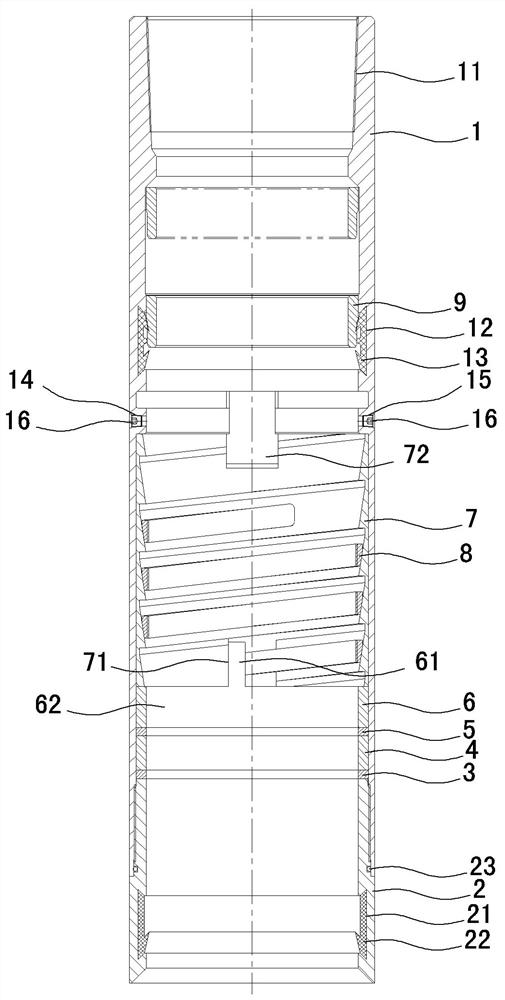

[0007] Such as figure 1 As shown, it includes an outer cylinder 1 and a guide shoe 2. The upper end of the outer cylinder 1 is provided with an internal thread 11 connected with the casing, the lower end of the outer cylinder 1 is axially connected with the upper end of the guide shoe 2 through threads, and the guide shoe 2 A lower sealing ring groove 21 is provided on the inner wall of the lower sealing ring groove 21, and a lower sealing ring 22 is arranged in the lower sealing ring groove 21 to seal and cooperate with the old casing. Matching lower spacer ring 3, lead seal ring 4, upper spacer ring 5, control card 6 and inner cylinder 7, the lower end surface of the lower spacer ring 3 matches the upper end surface of the guide shoe 2, and the upper end surface of the inner cylinder 7 matches the outer The inner end surface of the cylinder 1 facing downward is matched, and the inner wall of the outer cylinder 1 above the inner cylinder 7 is provided with an upper sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com