Optical lighting device and optical modification equipment

A lighting device, optical technology, applied in optics, optical components, instruments, etc., can solve the problems of poor energy efficiency ratio, large difference in radiation intensity, and difficulty in achieving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0034] If the optical lighting device is applied to the semiconductor wafer deposition film treatment as an example, the structure of the optical lighting device is a wafer, which is understood, except for the application. Based on the processing of the semiconductor wafer film, the optical lighting device can also be applied to other fields with similar needs, such as thin film optical modification treatment of the LED and tablet display industries.

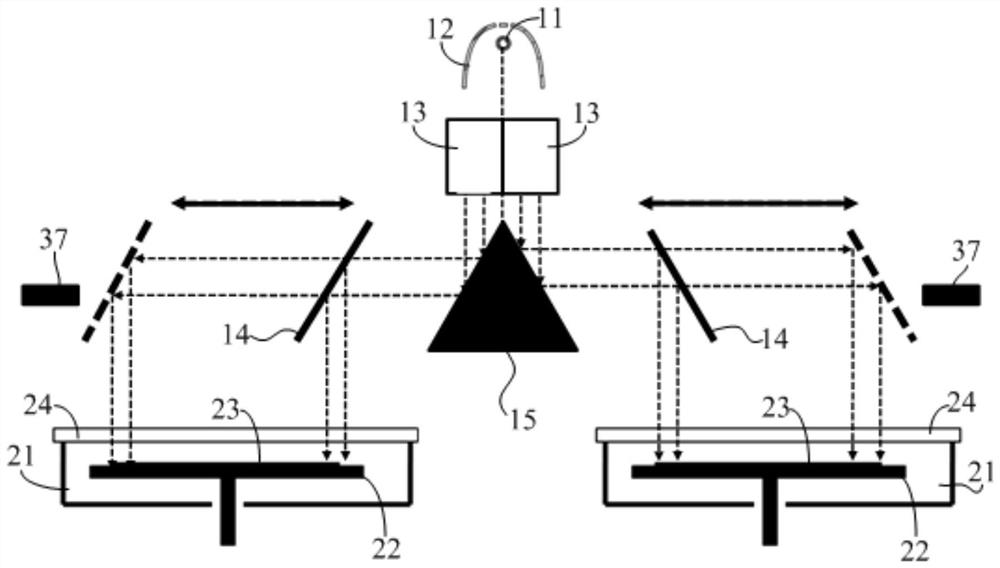

[0035] Please refer to figure 1 , figure 1 A simplistic diagram of an embodiment of the optical illumination device provided by the present invention.

[0036] In this embodiment, the optical illumination device includes a linear light source 11, a light modulation member 13, a relay reflective member 15, and two scanning mirror 14, and the light m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com