Breathing linkage device for aviation oxygen supply

A linkage device and oxygen supply technology, which is applied in the direction of respiratory protection devices, fire rescue, life-saving equipment, etc., can solve the problem of high cost, and achieve the effects of reducing loss, sealing reliability, and sealing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

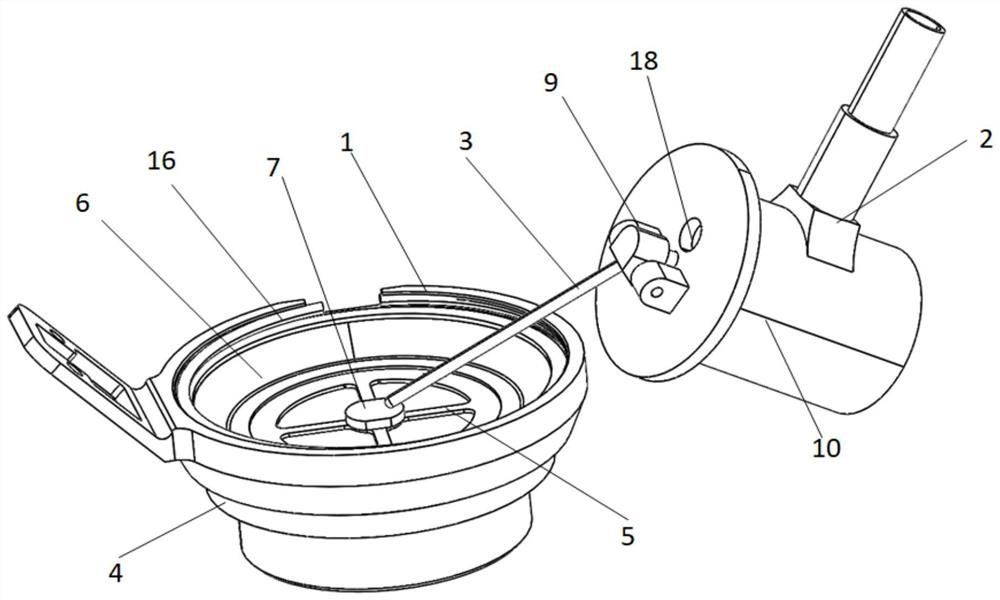

[0027] refer to Figure 1-8 , the present invention provides a technical solution, a respiratory linkage device for aviation oxygen supply, comprising a linked expiratory valve 1 and an inhalation module 2, and the linked exhalation valve 1 and the inhalation module 2 pass through a connecting rod 3 connections;

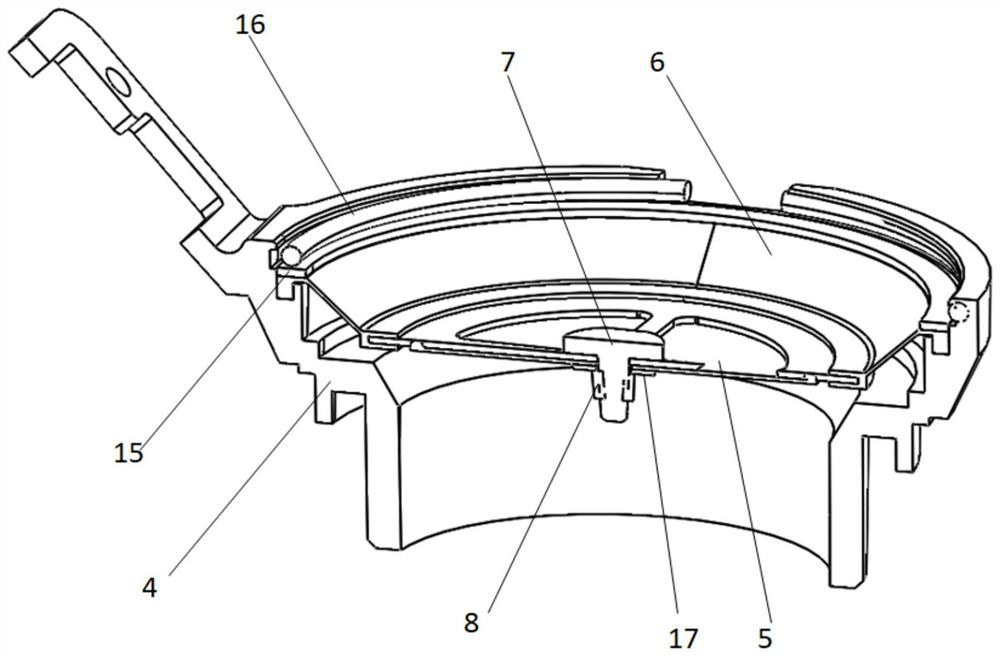

[0028] The linked exhalation valve 1 includes an exhalation base 4, an exhalation diaphragm 5 and an integrated diaphragm 6. The integral diaphragm 6 is arranged around the center of the exhalation base 4 and connected to the inner wall of the exhalation base 4. The exhalation diaphragm 5 is arranged on the inner side of the integral diaphragm 6 and connected with the inner wall of the integral diaphragm 6. The center of the expiratory diaphragm 5 is provided with a screw 7 and a lock nut 8. One end of the connecting rod 3 is connected to the top of the screw 7, and the bottom end of the screw 7 passes through Over-expiratory diaphragm 5 is connected with lock nut 8...

Embodiment 2

[0039] refer to Figure 1-8 , on the basis of Example 1:

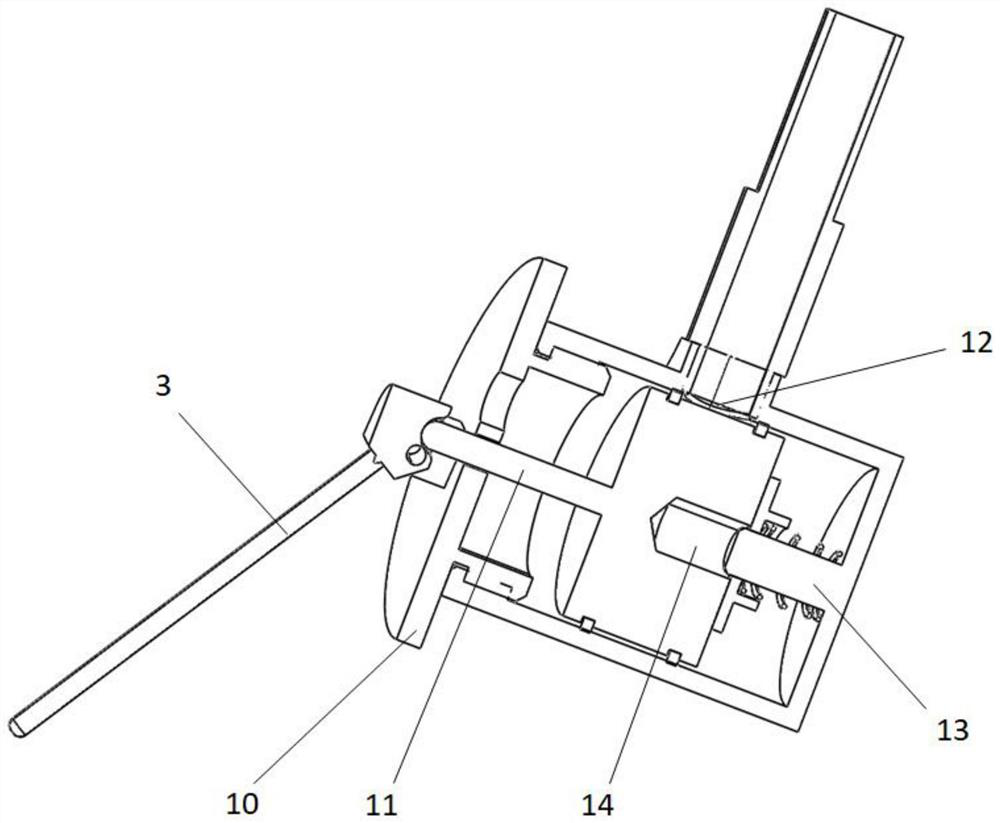

[0040] When there is a certain amount of oxygen in the cavity of the mask 20, slightly inhale, the cavity of the mask 20 is under a small negative pressure, which is affected by the pressure, such as Figure 4-5 , in the state of first-level lifting, the expiratory diaphragm 5 and the integrated diaphragm 6 in the interlocking exhalation valve 1 are lifted. At this time, the integrated diaphragm 6 is deformed, and the cross-section of the integrated diaphragm 6 is U Type, one end of the connecting rod 3 moves with the lifting of the screw 7, the other end of the connecting rod 3 drives the connecting rod seat 9 to rotate a small angle, the connecting rod seat 9 compresses the sealing shaft 11 in the suction module 2, and the sealing shaft 11 moves a certain distance , the air inlet 13 of the inhalation module 2 is in a half-open state, and oxygen enters the cavity of the face mask 20 through the half-open air inlet 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com