Auxiliary limiting stopper for clamp

A technology of stopper and fixture, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of workpiece deformation, quality decline, affecting sales and use, etc., and achieve the effect of avoiding over-tightening and avoiding pinch injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

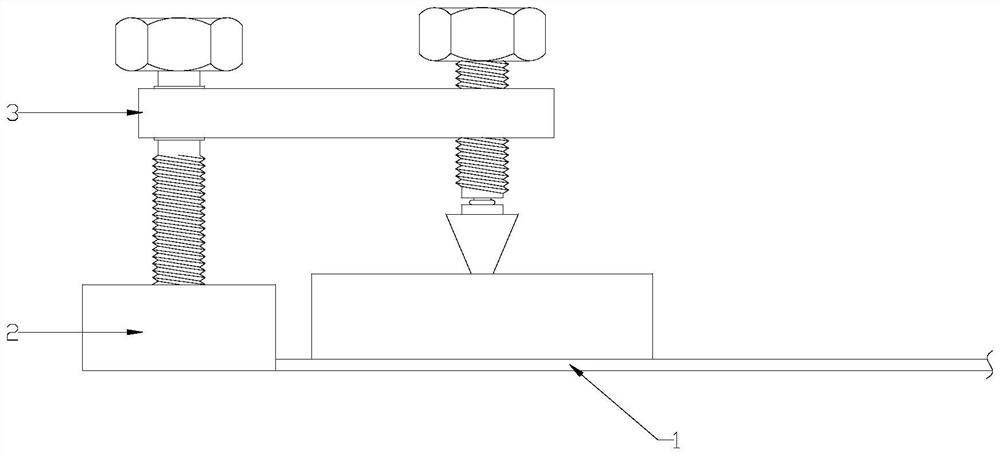

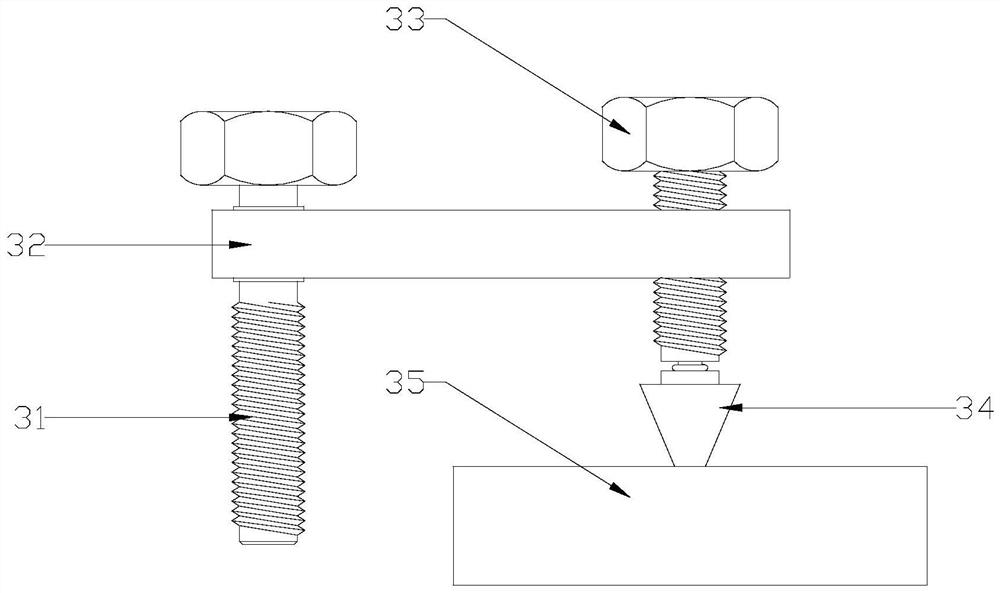

[0025] refer to Figure 1 to Figure 5 , an auxiliary limiter for clamps according to the present invention, including a positioning bolt 31, a support piece 32, a fastening bolt 33, a fastening block 34 and a fastening plate 35, the support piece 32 is arranged horizontally and one end is rotatably connected to the positioning The screw rod of the bolt 31 and the other end are screwed on the screw rod of the fastening bolt 33 , and the fastening block 34 is installed on the bottom end of the screw rod of the fastening bolt 33 and presses the top surface of the fastening plate 35 downward.

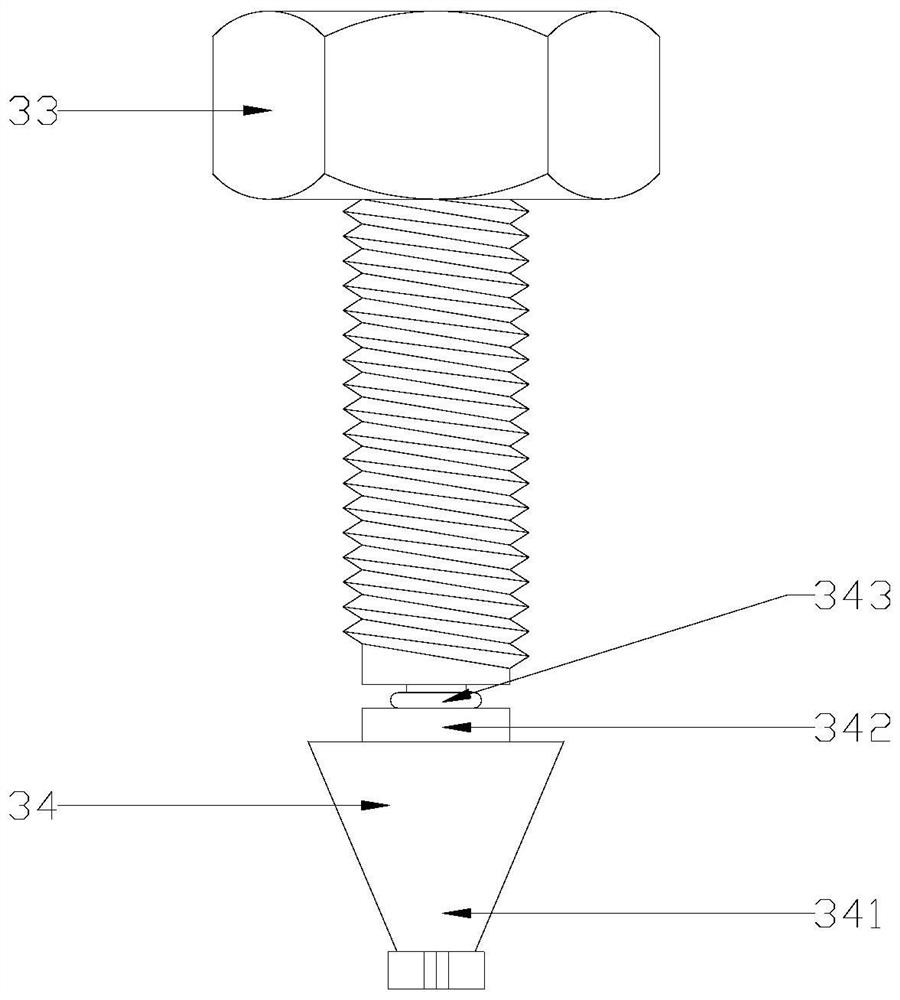

[0026] The fastening block 34 includes a terminal 341, a plug 342 and a spring 343. The bottom end of the screw rod of the fastening bolt 33 is provided with a blind hole 331, and the top end of the plug 342 is provided with a protrusion extending into the blind hole 331. strip 3421, the bottom end of the plug 342 is rotatably connected to the top end of the terminal 341, the spring 343 is ...

Embodiment 2

[0035] refer to Figure 1 to Figure 6 , also includes screw drive 36 and controller, and described screw drive 36 comprises nut 361, gear 362 and motor 363, and described nut 361 and gear 362 all can be rotatably connected in the support plate 32, on the outer wall of described nut 361 It is provided with teeth and meshes with the gear 362. The motor 363 is installed on the support plate 32 and drives the gear 362 to rotate. The screw of the fastening bolt 33 is threaded with the nut 361, and the screw driver 36 is connected with the controller. electrical connection.

[0036] A thickened portion 321 is provided at the place where the nut 361 is mounted on the support piece 32 .

[0037] A pressure sensor 37 is installed in the fastening plate 35, and the pressure sensor 37 is electrically connected with the controller.

[0038] Others are the same as embodiment one.

[0039] When the clamping block 341 extends into the notch, the motor 363 can be directly used to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com