Data-driven rotor system typical fault automatic identification method

A typical fault, data-driven technology, applied in the field of fault identification, can solve problems such as inability to accurately identify fault characteristics, and achieve the effect of reducing data modeling time and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

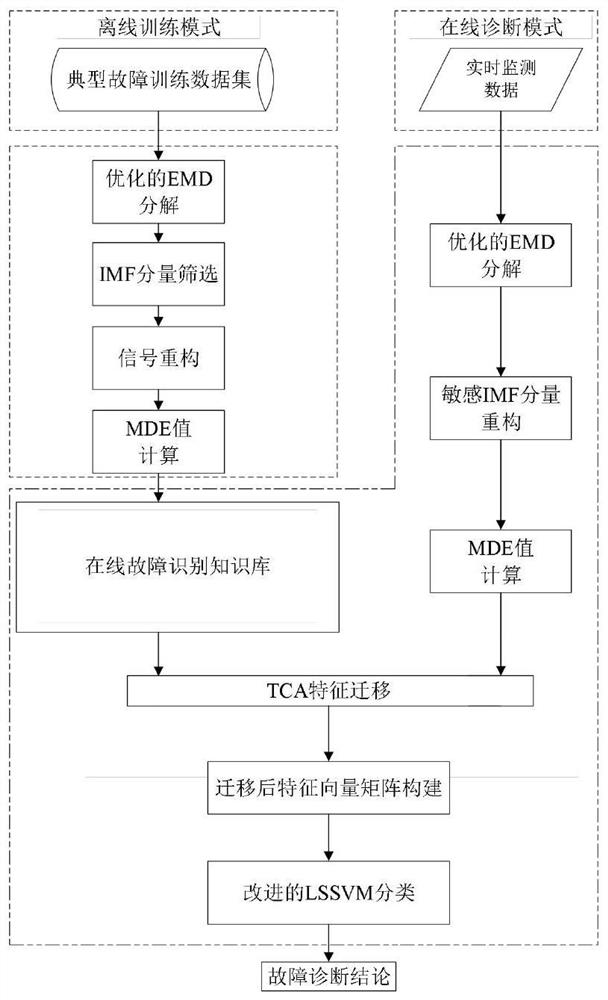

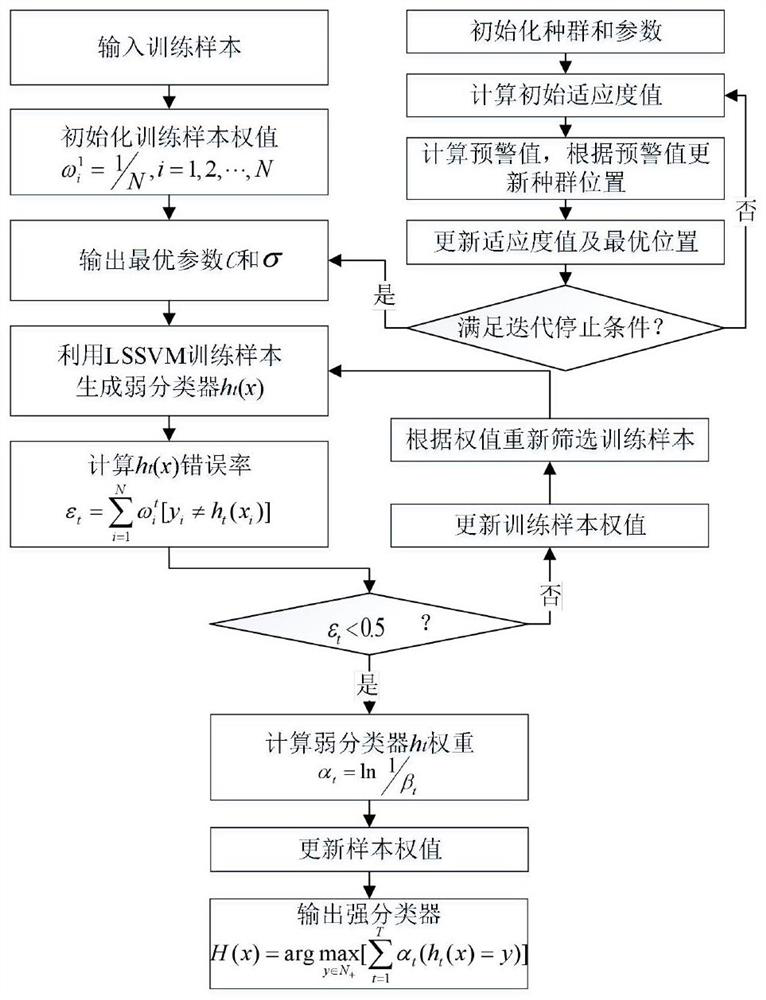

Method used

Image

Examples

Embodiment Construction

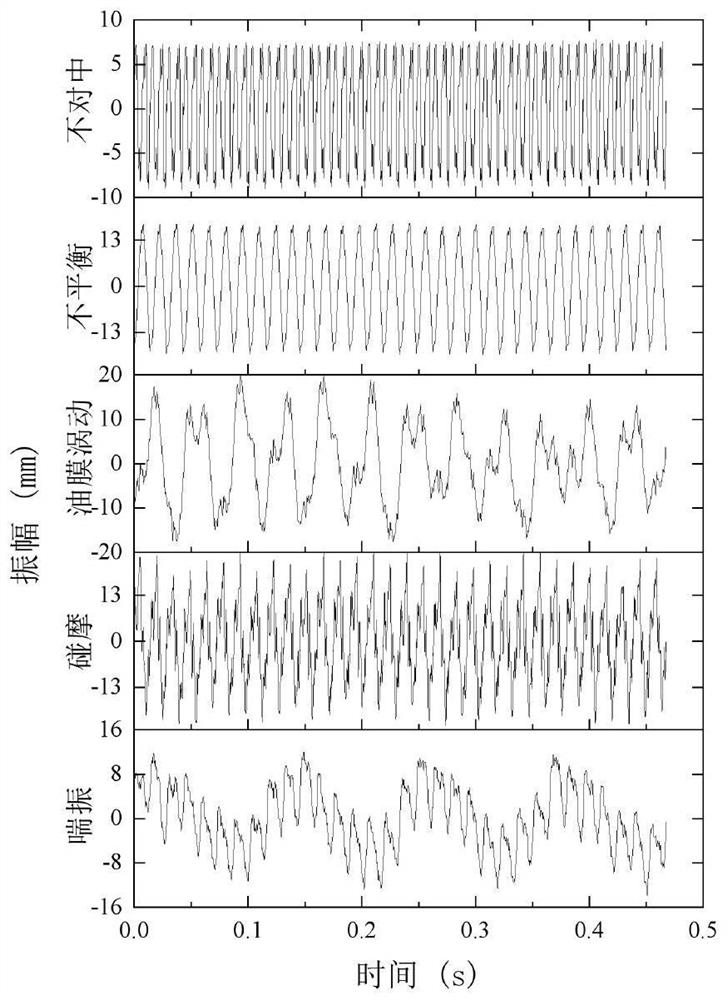

[0048] In order to describe the above process in detail, taking the typical fault label data of a company's real centrifugal compressor, steam turbine, and flue gas turbine rotor system as an example, select shaft misalignment, rotor unbalance, The data of five typical fault cases of oil film whirl, rubbing and surge are used as training data. The description of the training data is shown in Table 1. There are 150 sets of data for each type of fault state, and a total of 750 sets of data are used as training sets.

[0049] Table 1. Training dataset description

[0050]

[0051]

[0052] (1) adaptively determine the value of parameter K by ABC algorithm;

[0053] (2) Using the EMD method to decompose the rotor system diagnostic signal into a series of IMF components;

[0054] (3) Screening sensitive IMF component reconstruction through sensitive IMF component evaluation index;

[0055] (4) Calculate the 15 scale MDE values of the reconstructed signal;

[0056] (5) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com