Internal medicine pressing hemostasis device

A technology of internal medicine and airbag belt, applied in tourniquet, medical science, surgery, etc., can solve the problems of prolonging the duration of wound pain, tissue damage, prolonging the period of wound self-healing, etc., to avoid secondary damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

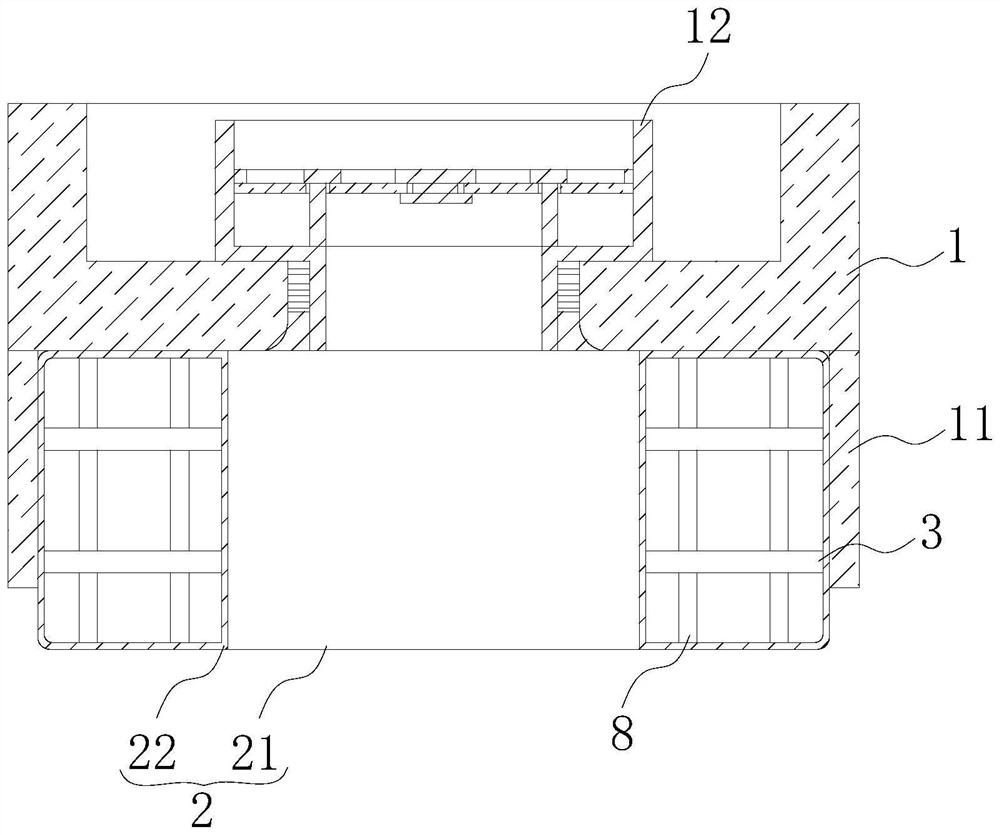

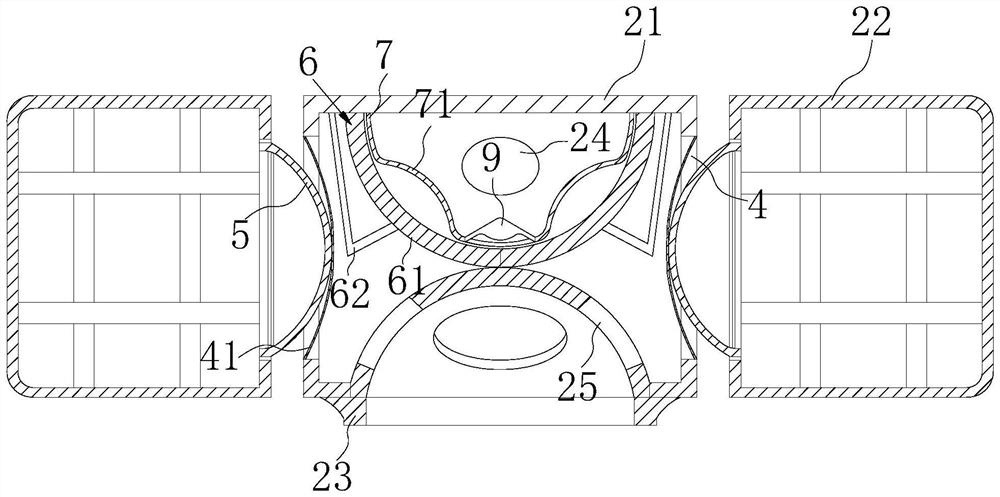

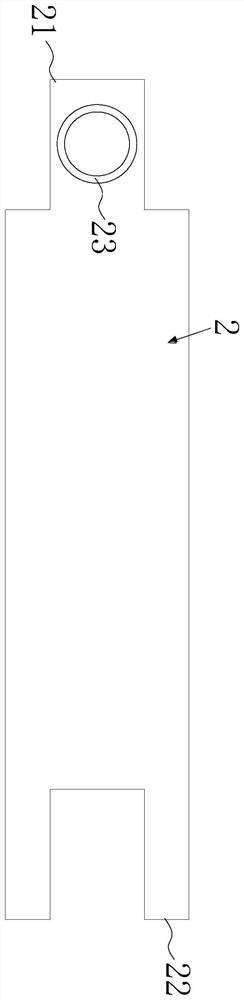

[0030] Such as Figure 1-4 As shown, a compression hemostasis device for internal medicine includes an air nozzle seat 1 and an air bag belt 2. One end of the air bag belt 2 is fixed on the air valve seat 1, and the other end wraps around the wrist arm and is fixed on the air valve seat 1 to form a circular shape. structure;

[0031] The airbag belt 2 is provided with a grid-shaped elastic rib frame, which is limited by the pulling of the grid-shaped elastic rib frame, so that the airbag belt 2 expands in a circular structure;

[0032] The air nozzle seat 1 is connected with an external inflatable device, so that the inside of the air bag belt 2 inflated in a circular structure maintains a predetermined air pressure for squeezing the wound to st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com