Preparation method of matrix protective coating

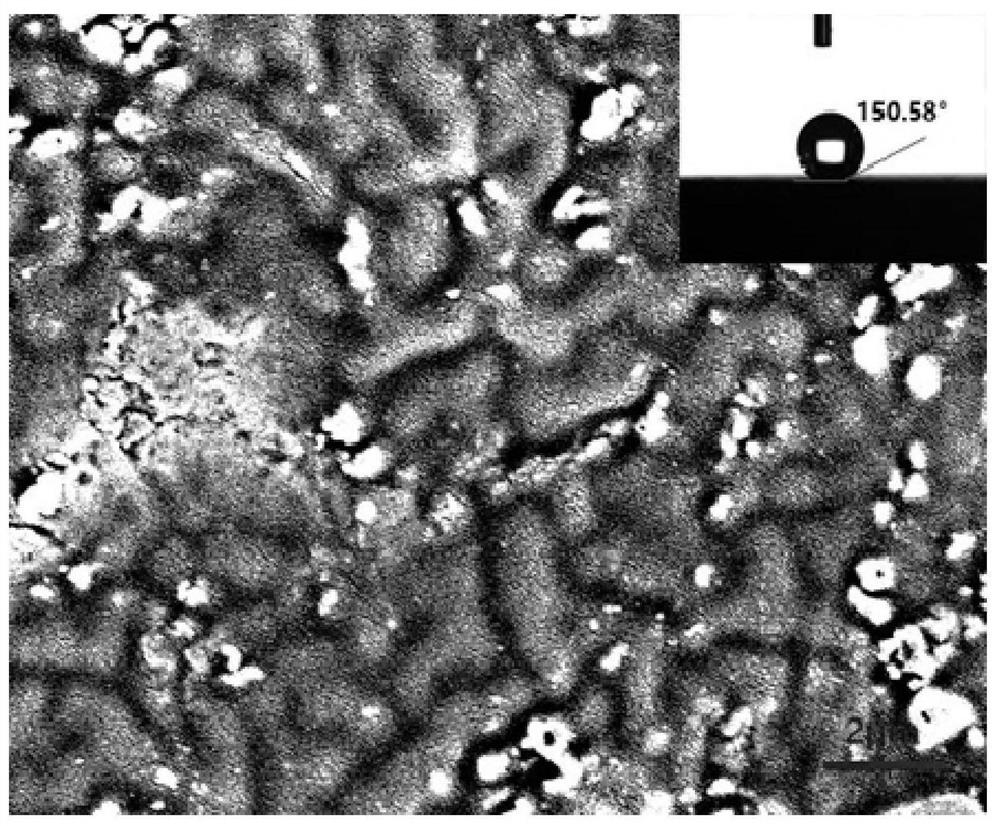

A protective coating and matrix technology, applied in the field of matrix protective coating preparation, can solve the problem that the wear resistance of the coating cannot meet the application requirements, and achieve excellent super-hydrophobic performance, improved wear resistance, and excellent corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

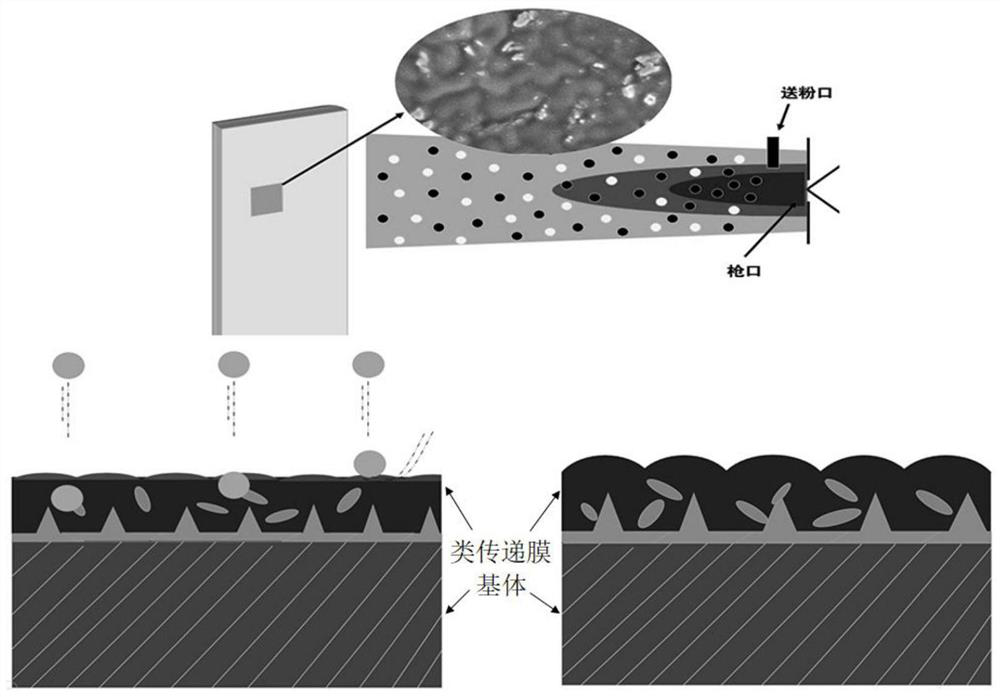

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of substrate protective coating, concrete steps are as follows:

[0028] A. Pretreatment, including:

[0029] a) Substrate preparation: take a 316L stainless steel workpiece with a size of Φ25mm*6mm, and carefully polish it with sandpaper to remove burrs, welding slag, sharp corners, etc. on the surface;

[0030] b) Sand blasting treatment: use 0.3-0.4MPa dry and clean compressed air as the power, the spray distance is 150mm, and the spray angle is 70°-90°, and the 150-mesh white corundum abrasive with multi-angular particles is sprayed onto the surface of the substrate at high speed to remove surface impurities. Thoroughly clean and roughen the surface to obtain a pre-treated surface;

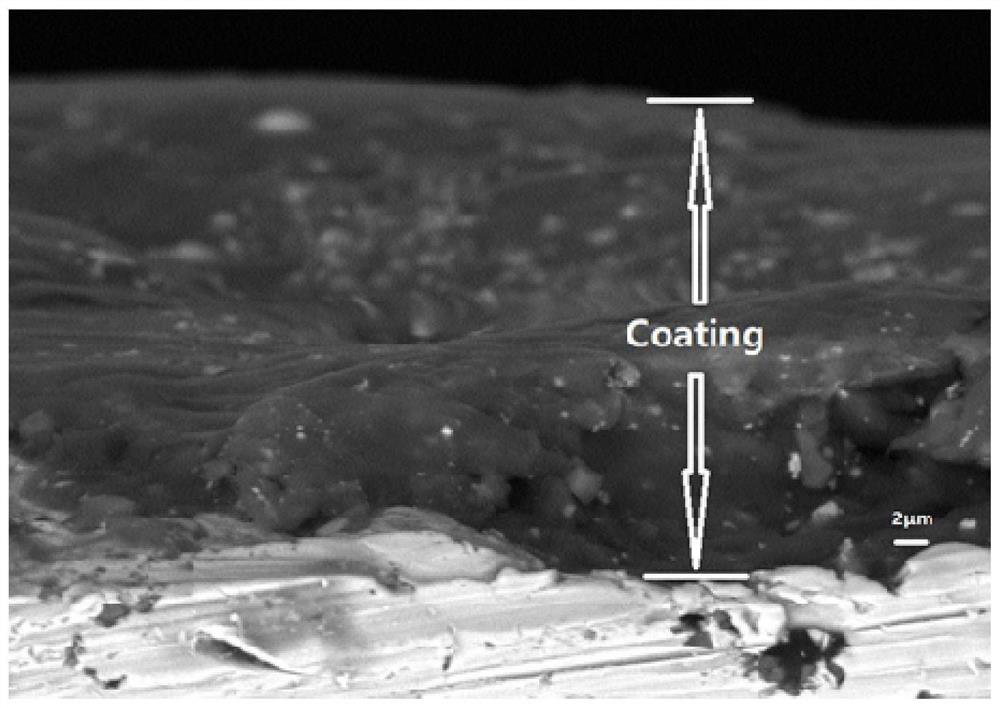

[0031] B. Preparation of wear-resistant coating:

[0032] a) It will be composed of zirconia-yttria powder, namely YSZ powder (the content of yttrium oxide in the powder is 8wt%) and polytetrafluoroethylene powder (PTFE powder) according to the mass percentage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com