Magnetic disk inspection method for magnetic disk device, and magnetic disk device

A technology of a magnetic disk device and an inspection method, which is applied in the field of disk inspection of a magnetic disk device and the field of a magnetic disk device, and can solve problems such as poor recording signal quality, difficulty in reading recorded information, and reduced recording quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

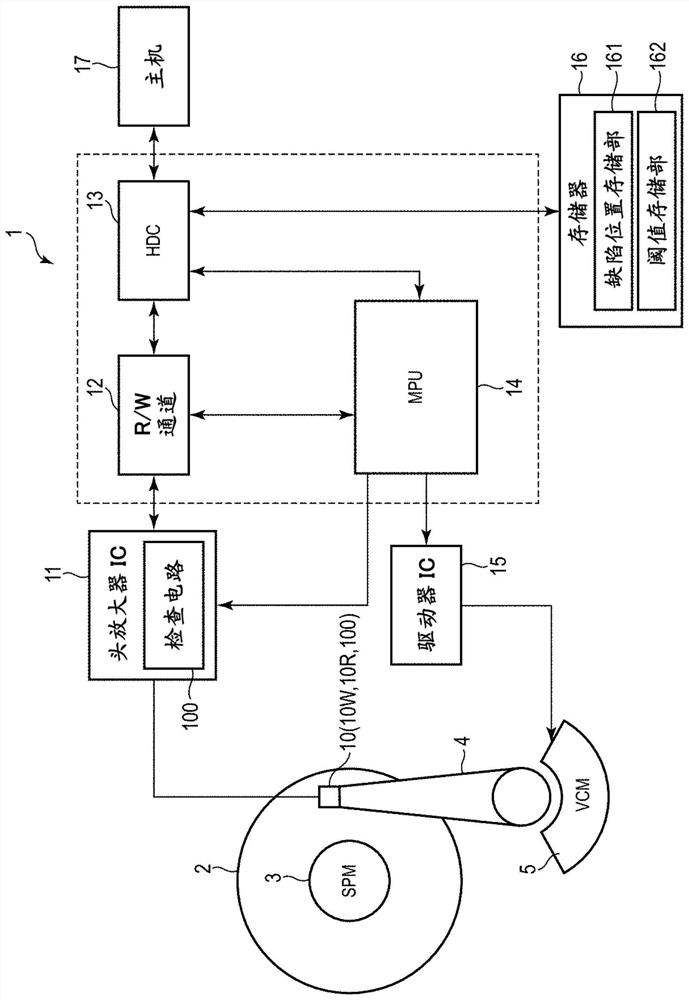

[0029] figure 1 It is a block diagram showing an example of the configuration of the magnetic disk drive 1 according to the first embodiment.

[0030] Such as figure 1 As shown, the magnetic disk device 1 is configured as, for example, a hard disk drive (HDD). The magnetic disk device 1 includes a magnetic disk 2, a spindle motor (SPM) 3, an actuator 4, a voice coil motor (VCM) 5, a magnetic head 10, a head amplifier IC (preamplifier) 11, an R / W channel 12, and a hard disk controller ( HDC) 13 , microprocessor (MPU) 14 , driver IC 15 , and memory 16 .

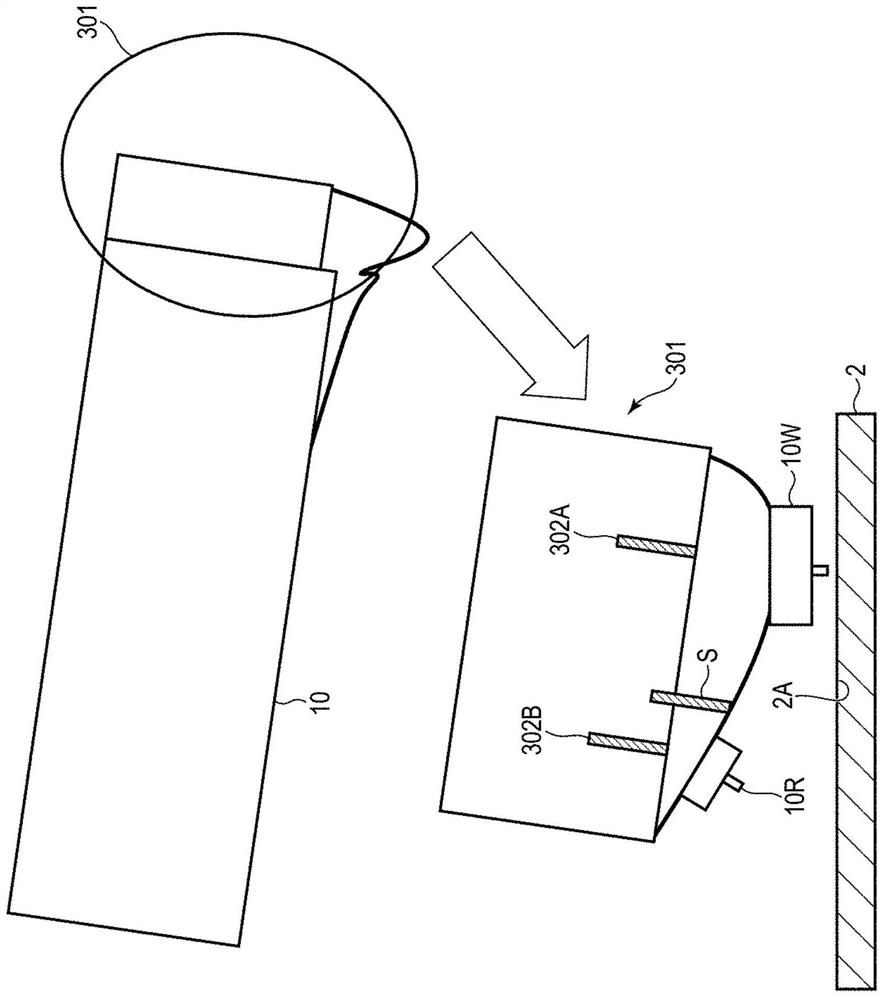

[0031] In addition, the magnetic disk device 1 can be connected to the host computer 17 . Although the details will be described later, the magnetic head 10 includes a write head 10W, a read head 10R, and a spin-torque oscillator (Spin-Torque-Oscillator: STO) 100 as a high-frequency oscillation element. In addition, the R / W channel 12, the HDC 13 and the MPU 14 can also be assembled in an integrated circuit of a single ch...

no. 2 Embodiment approach

[0094] The second embodiment is different from the first embodiment in that a defect of the magnetic disk 2 is detected not in units of tracks but in units of sectors. Therefore, the configuration and processing for detecting defects on a sector-by-sector basis will be described in detail. In addition, the same code|symbol is attached|subjected to the same structure as 1st Embodiment, and detailed description about these structures is abbreviate|omitted.

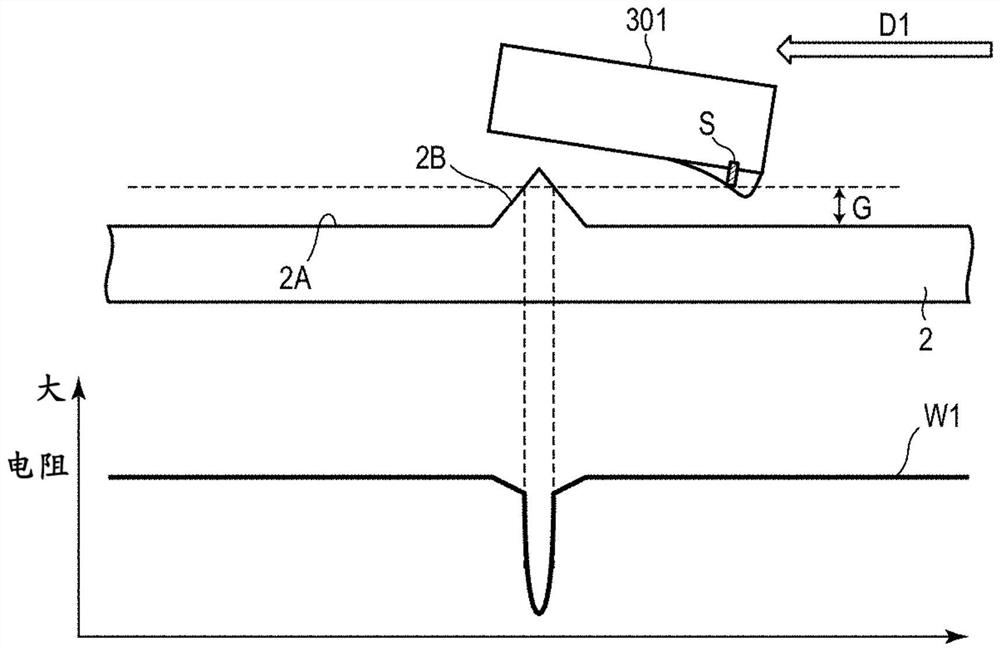

[0095] When the defect of the magnetic disk 2 is a defect such as a groove constituted by the concave portion 2C along the circumferential direction of the track, the length of the groove may be limited. For example, when a track is composed of a plurality of sectors, a case where a defect is accommodated in one sector is also considered. In this case, it is assumed that when the LPF outputs in one track are averaged, the output level becomes small, so that the detection sensitivity deteriorates, and the presence of a defec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap