Tunnel pipe distribution vehicle with protection function

A protective function and the technology of pipe-laying vehicles, which are applied in the direction of freight vehicles, vehicles used to carry long goods, motor vehicles, etc., can solve the problems that the side of the pipe cannot be blocked and protected, and can avoid the pipe from falling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

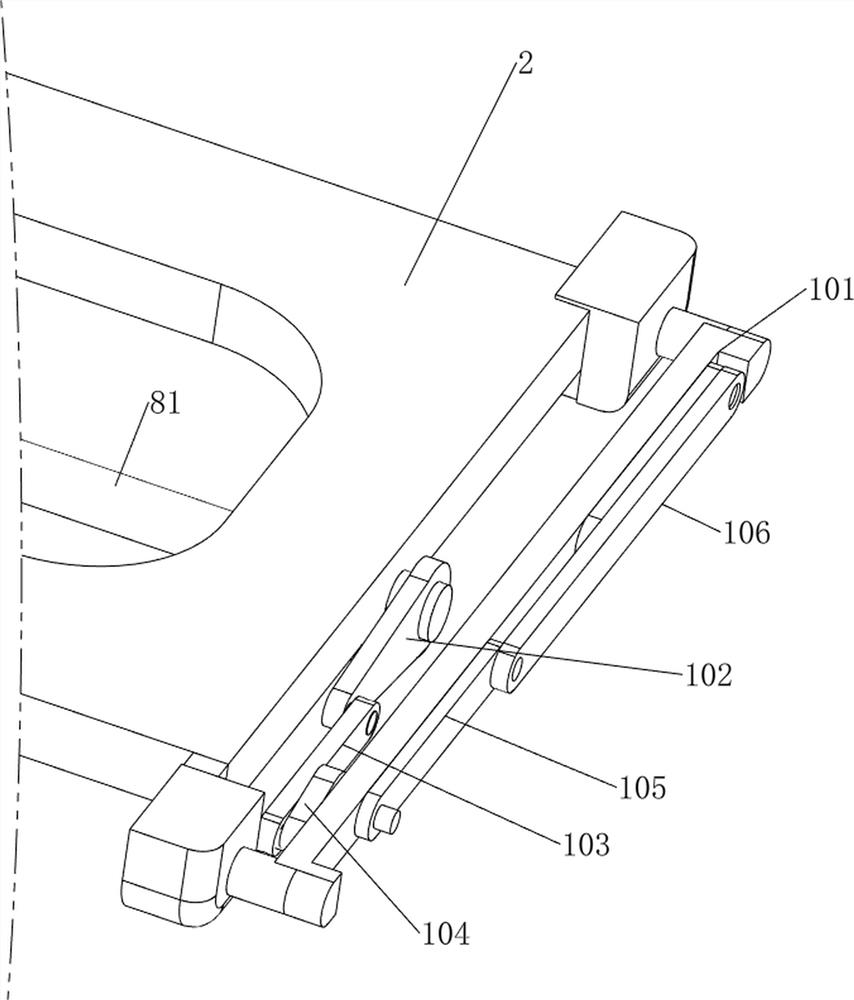

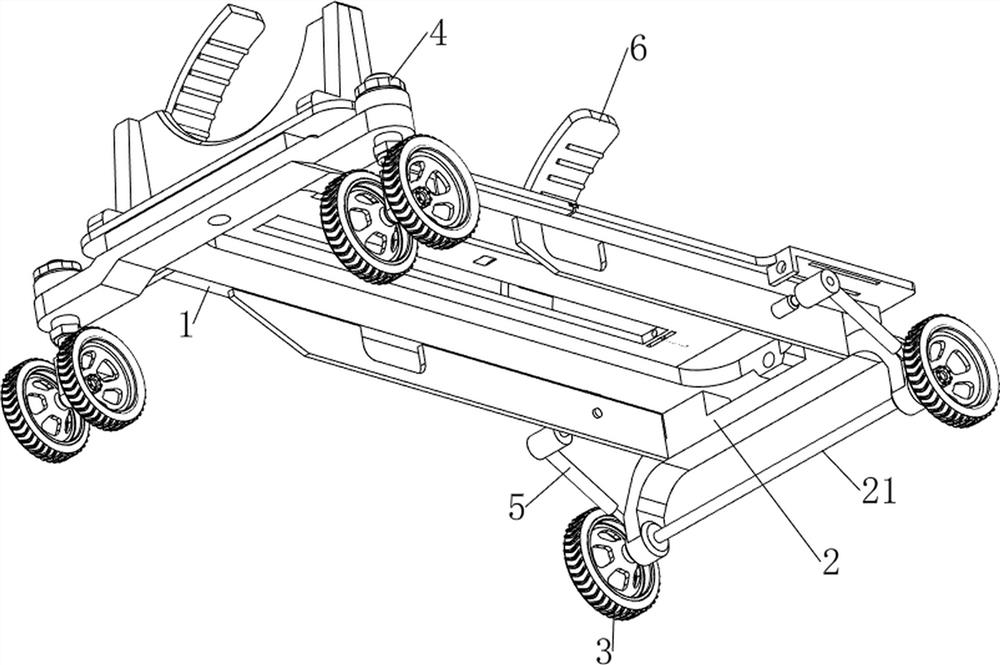

[0032] A tunnel pipe laying vehicle with protection function, such as Figure 1-3 As shown, it includes a bearing plate 1, a support frame 2, a connecting shaft 21, a wheel 3, a load-bearing rod 4, a support rod 5, a first protective plate 6, a closing mechanism 7 and a limit mechanism 8, and the bottom of the bearing plate 1 is provided with a support Frame 2, the support frame 2 can support the bearing plate 1, the lower part of the right side of the support frame 2 is rotatably connected with a connecting shaft 21, and the front and rear sides of the connecting shaft 21 are connected with wheels 3, the wheels 3 can roll on the ground, and the support frame 2 The front and rear sides of the left part are all rotatably connected with a load-bearing bar 4, and the load-bearing bar 4 is also rotatably connected with a wheel 3. The first protective plate 6, the first protective plate 6 can be used to protect the pipeline, the support frame 2 is connected with a closing mechanism...

Embodiment 2

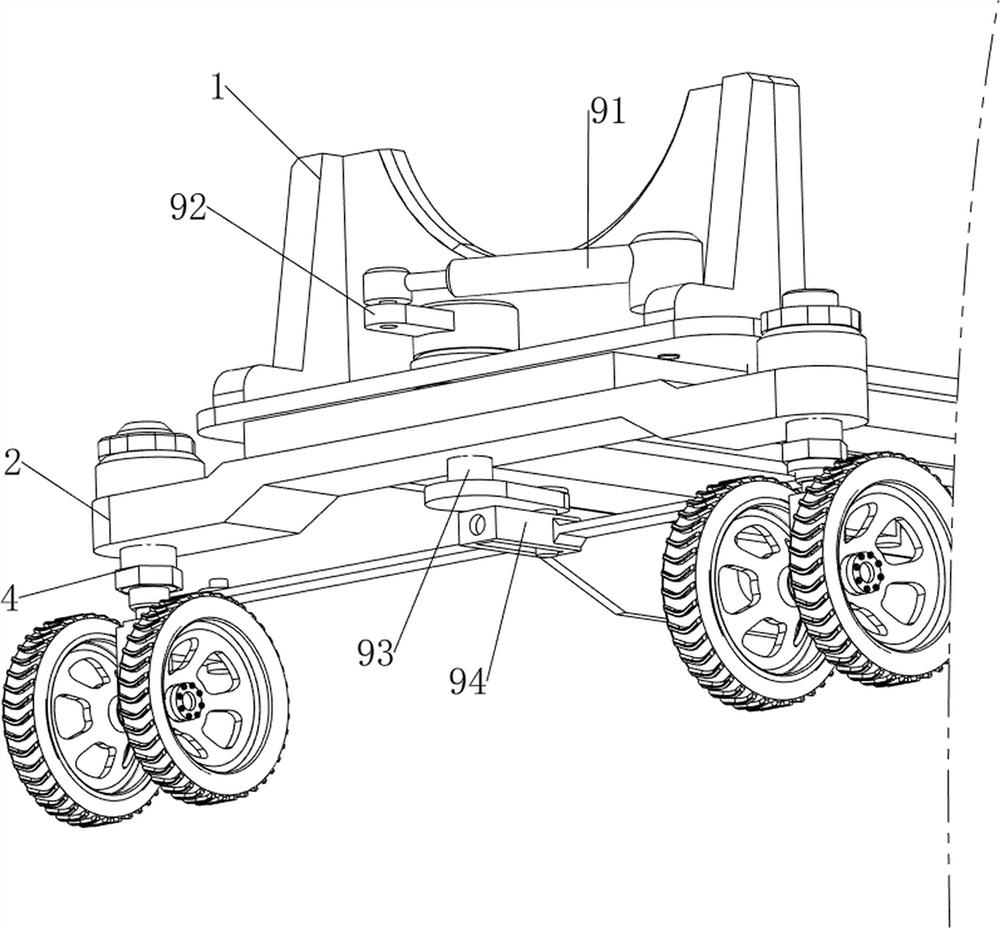

[0037] On the basis of Example 1, such as figure 1 , figure 2 , Figure 7 and Figure 8 As shown, an adjustment mechanism 9 is also included, which can adjust the steering of the left wheel 3, and then adjust the moving direction. The adjustment mechanism 9 includes a cylinder 91, a first rotating rod 92, a second rotating rod 93 and a second connecting rod 94 The left front side of the bearing plate 1 is connected with a cylinder 91 by screws, the second rotating rod 93 is rotationally connected between the bearing plate 1 and the left middle part of the support frame 2, and the first rotating rod 92 is welded on the left side of the upper part of the second rotating rod 93 , the first rotating rod 92 and the telescopic rod of the cylinder 91 are connected in a rotational manner, and the telescopic rod of the cylinder 91 can drive the first rotating rod 92 to rotate. A second connecting rod 94 is connected, and the second connecting rod 94 is slidingly connected to the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com