Pipeline penetrating plate fixing structure based on spring pushing type water supply and drainage design

A technology for fixing structures and drainage pipes, which is applied to pipes, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve the problems of large gaps in flange holes, troublesome operation, and difficulty in ensuring the neutrality of pipes, so as to avoid pipe movement , Easy to use, good fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

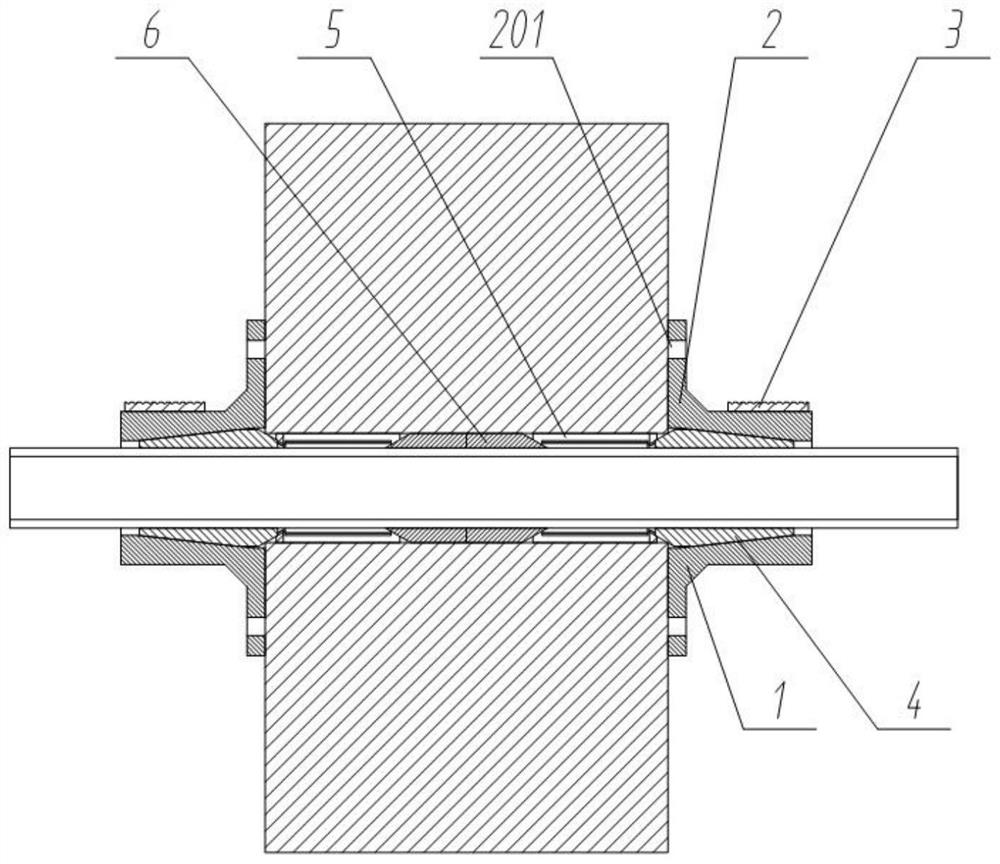

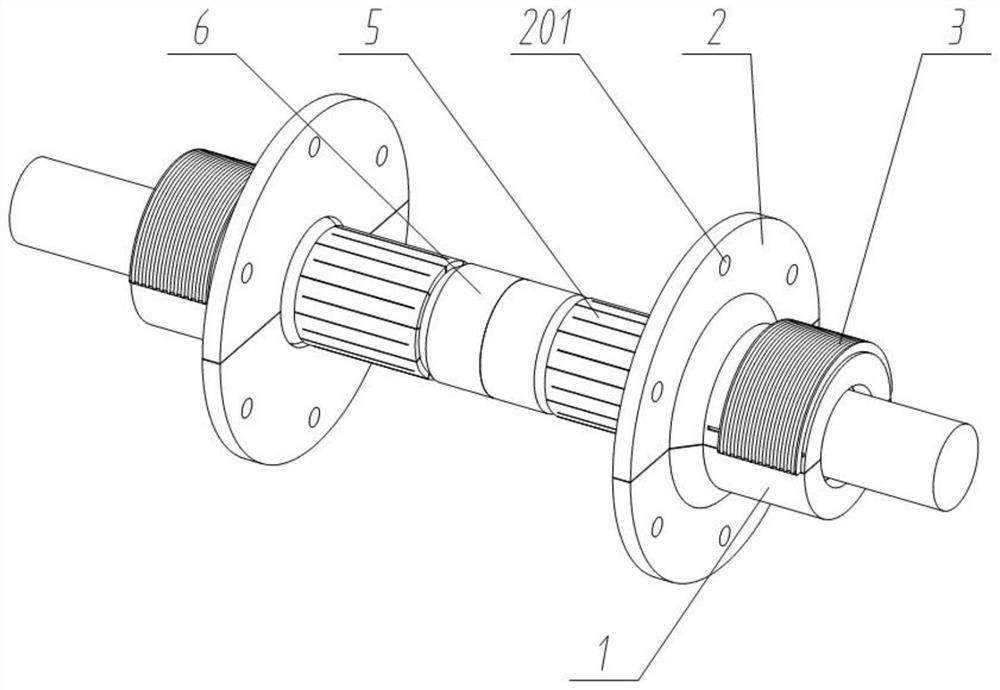

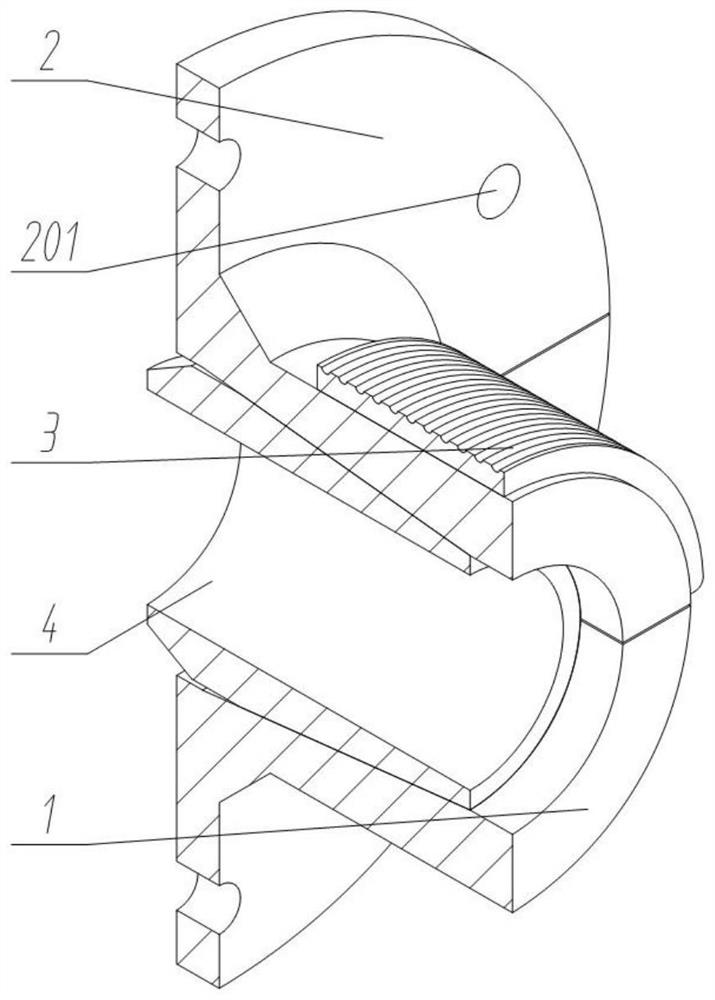

[0046] Example: Please refer to Figure 1 to Figure 8 :

[0047] The present invention proposes a spring-push type water supply and drainage design pipeline through-plate fixing structure, including: a lower end cover 1;

[0048] The lower end cover 1 is provided with two groups, and the two groups are respectively located on both sides of the through-board;

[0049] The upper end cover 2, the upper end cover 2 is plugged and connected to the upper end surface of the lower end cover 1 through the spring pushing and clamping assembly, the upper end cover 2 and the lower end cover 1 form a flange-shaped end cover structure, and the flange-shaped end cover structure is sleeved on the drainage pipe outside, furthermore, according to an embodiment of the present invention, such as Figure 5 As shown, the upper end cover 2 also includes: mounting holes 201, and three sets of mounting holes 201 are evenly opened on the flange surfaces of the upper end cover 2 and the lower end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com