Hammer head group and preparation method thereof

A hammer and component technology, which is applied to stringed instruments, instruments, etc., can solve the problem of insufficient sound of hammers hitting strings, and achieve the effect of improving sound quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following is attached Figure 1-8 The application is described in further detail.

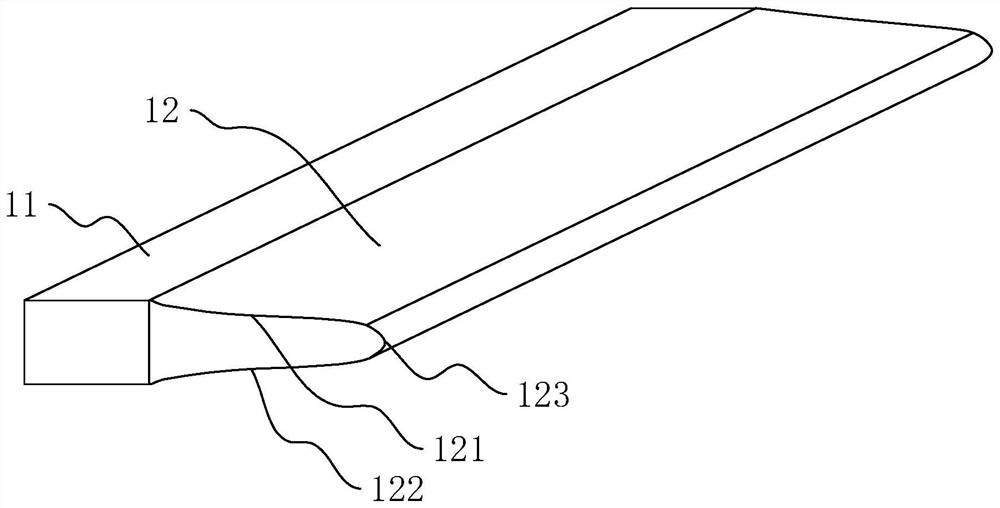

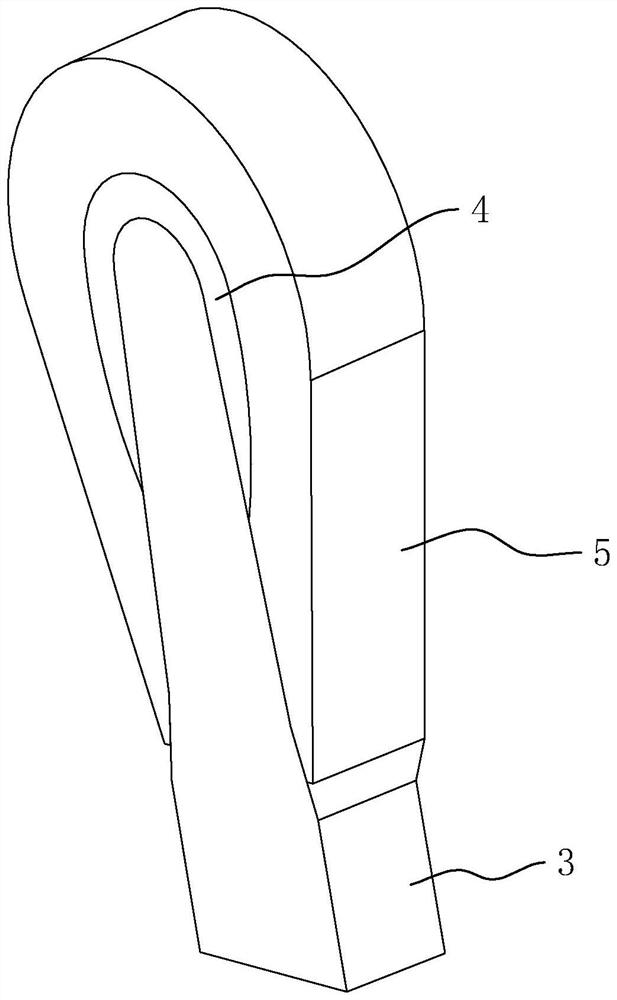

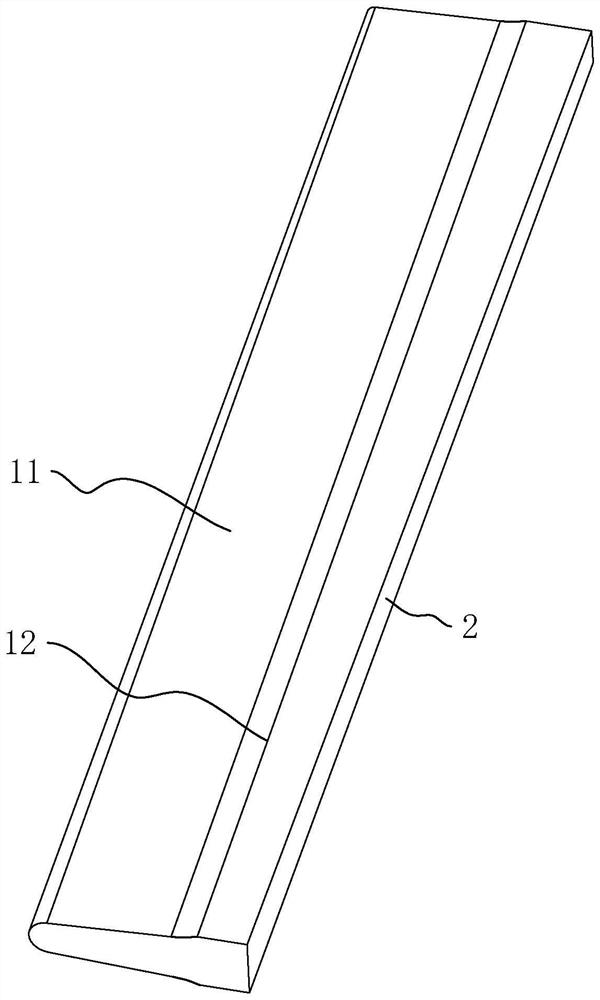

[0055] The embodiment of the present application discloses a hammer set. A hammer set includes high register hammers, middle register hammers, and low register hammers arranged in sequence. The hammers in the treble range, the hammers in the middle range and the hammers in the low range are all composed of a hammer last layer 3 , an inner felt layer 4 and an outer felt layer 5 sequentially compounded from inside to outside. The height of the hammer in the bass area (the distance between the highest point and the lowest point of the hammer) is 64.4±0.4mm, and the thickness (the side of the outer felt layer 5 of the hammer away from the inner felt layer 4 and the inner felt layer 4 close to the hammer last layer 3 The maximum horizontal distance between them) is 33.0±0.5 mm and the distance between the highest point of the felt and the highest point of the hammer last is 15.0±0.5mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com