Medium-length hole ore matching type mining method for steeply inclined thin vein

A mining method and technology for thin ore veins, applied in the field of deep hole blending mining, can solve the problems of high mining cost, low loss dilution rate, low efficiency, etc., and achieve the effect of speeding up the progress of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The average thickness of the ore body in a mine is 0.7m, the inclination angle of the ore body is 85-90 degrees, the length of the ore body varies greatly, and the average length is between 200-1000m. The average number of mineable veins in each segment is 1-3. If the spacing is more than 3m, simultaneous blasting and caving mining of multiple ore veins cannot be realized. In order to control dilution, only a single ore vein can be considered for mining one by one, which is basically consistent with the basic situation of steeply inclined thin vein mines. The application of this example can help solve the problem of conventional steeply inclined thin vein mines Common mining problems of ore veins, specific technical applications are:

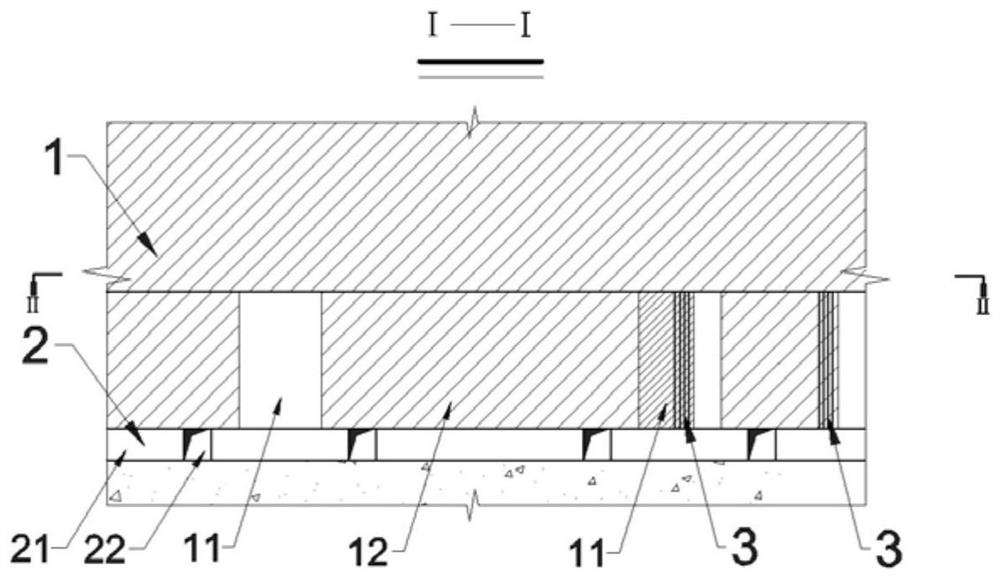

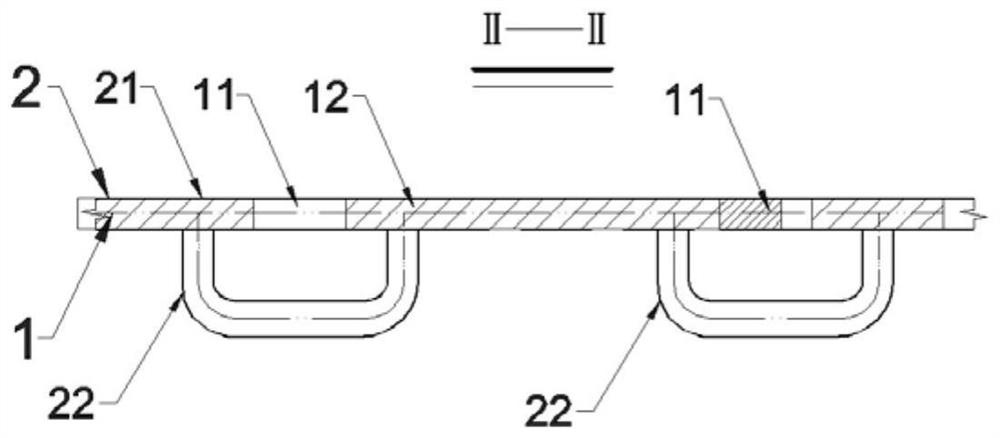

[0038] Such as figure 1 It shows the high-efficiency mining technology of mid-deep hole ore distribution type with steeply inclined thin veins according to an embodiment of the present invention. The ore body is divided into sections alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com