Stepped low-depletion mining method with combination of vertical medium-length holes in steeply inclined thin vein

A mining method and technology of steep inclination, which is applied in the field of steeply inclined thin veins combined with upper and lower to medium and deep holes combined with step-type low-dilution mining, can solve the problems of reducing the amount of mining engineering, reduce the amount of mining engineering, and increase mining capacity , The effect of shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

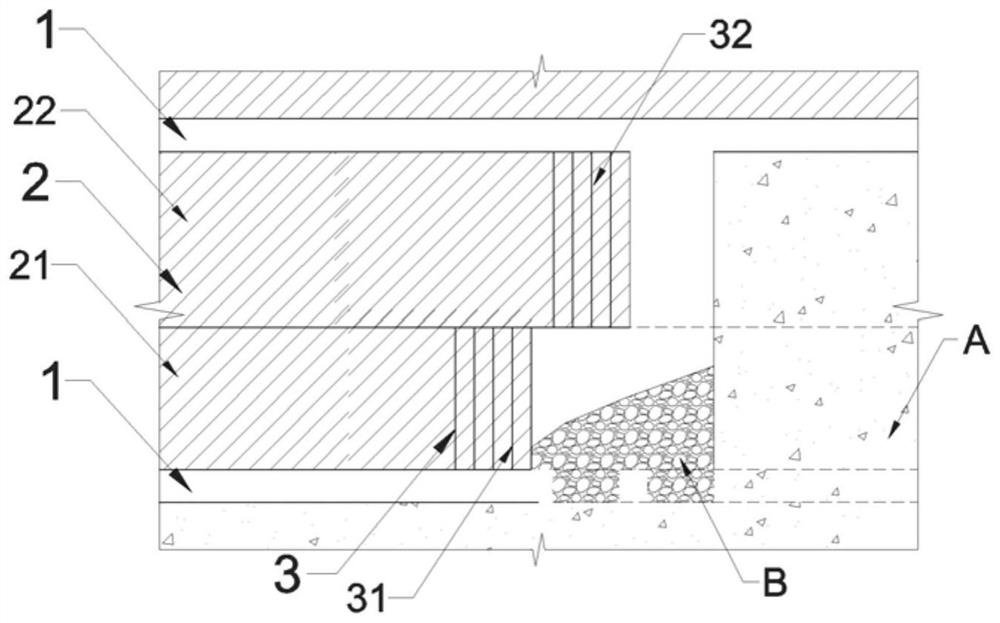

[0020] like figure 1 As shown, the present invention proposes a stepwise low-dilution mining method combining up and down to medium and deep holes for steeply inclined and thin veins. For mining with steeply inclined and thin veins, the stepwise mining method combined with up and down to medium and deep holes reduces the single The blasting height of medium and deep holes can effectively control the blasting force, reduce the maximum charge amount of single blasting, and greatly reduce the amount of super blasting, so as to realize the optimal dilution rate of medium and deep hole blasting in steeply inclined thin veins and improve the ore supply grade. It includes But not limited to the following specific steps and conditions:

[0021] A. Divide the ore body into sections along the depth direction, and the height of each section should be based on the stable conditions of the ore rocks of each section and be less than the height of the stable section to ensure that the mining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com