Long-distance drilling and grouting method for covering rock stratum through single-access non-sill-pillar sublevel caving method

A sub-caving method and drilling grouting technology, applied in drilling equipment and methods, drilling equipment, directional drilling, etc., can solve the problems that plague the mining industry, large ore loss and dilution, and achieve fast construction speed and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described,

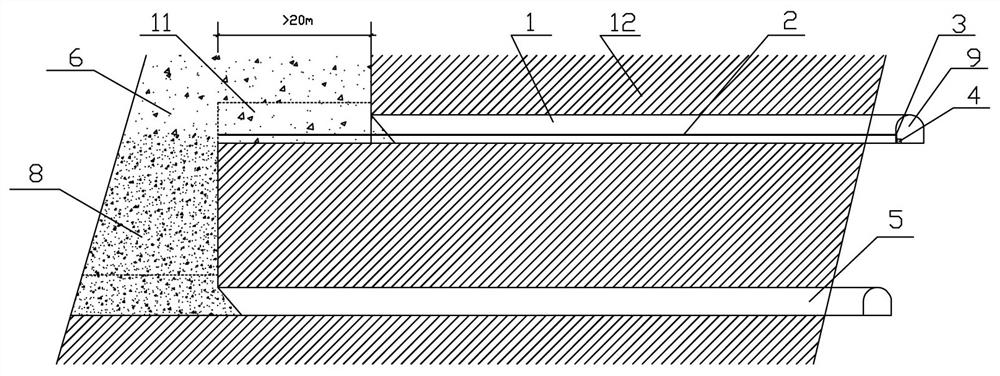

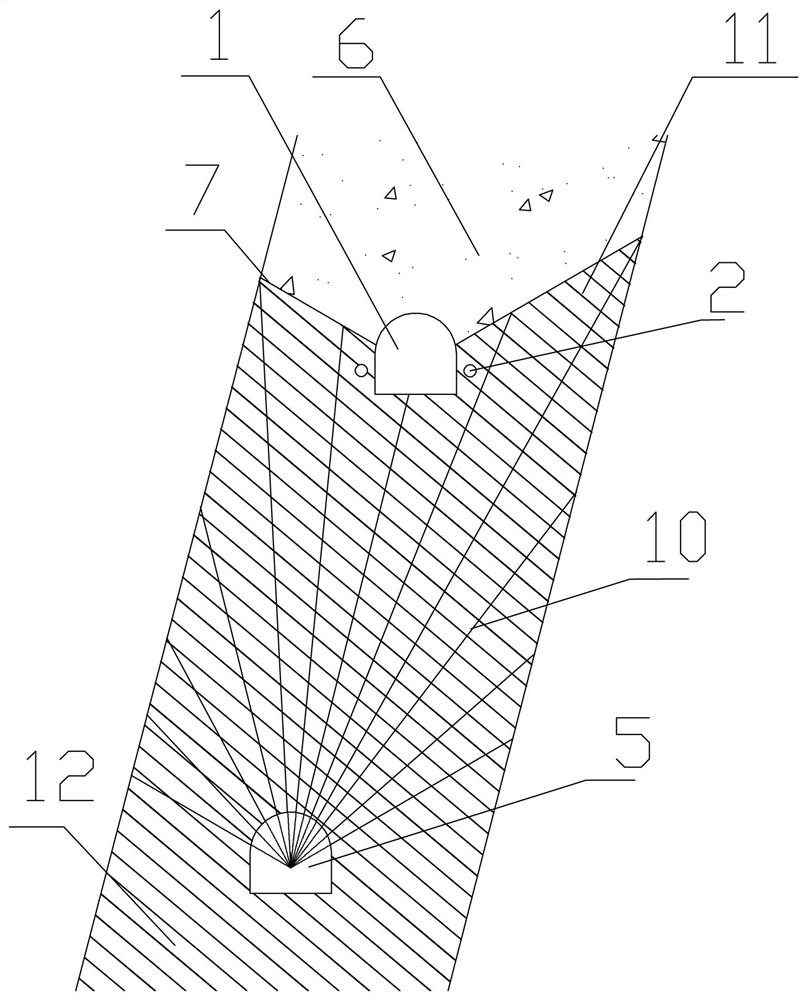

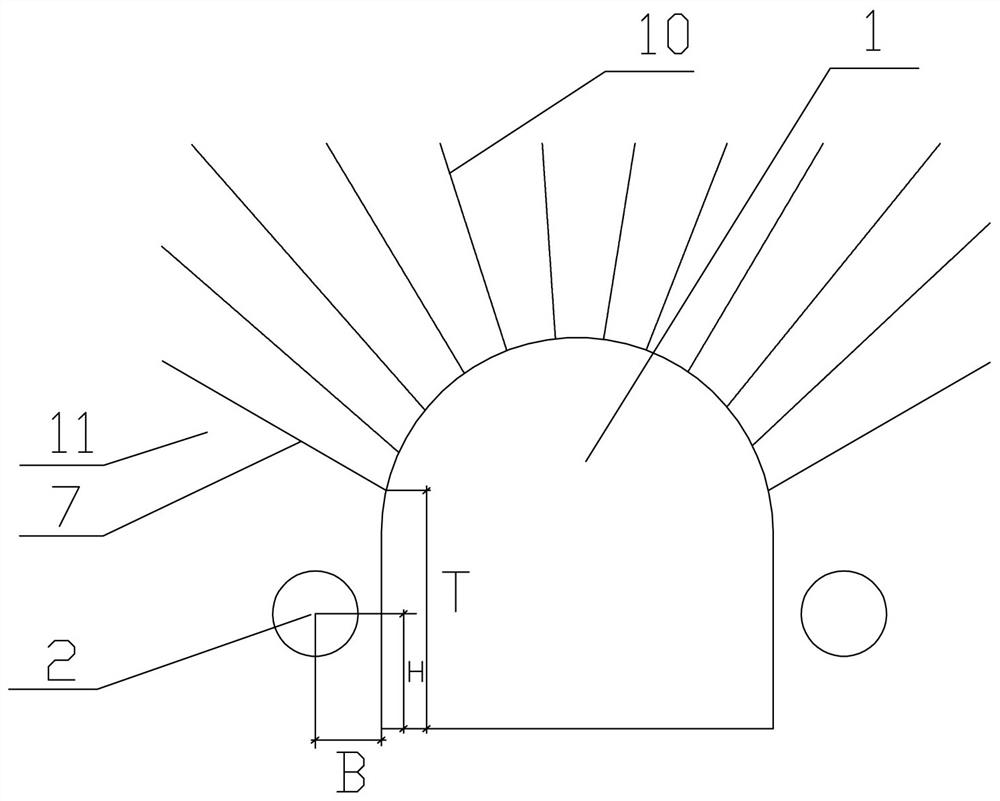

[0024] Such as Figure 1-Figure 3 As shown, the method for long-distance drilling and grouting of the single-entry non-bottom column segmented caving method of the present invention is characterized in that it comprises the following steps:

[0025] Step 1. Arrange drilling and grouting channels

[0026] In the connecting road 9 of the uppermost segment of the segmental caving method without pillars, the geological horizontal directional drilling machine is used to drill the grouting drilling channel 2 in the two side walls of the uppermost segmental mining roadway 1 full length, and the drilling construction is completed. Finally, insert the connecting pipe 3 at the orifice end of the grouting drilling channel 2, one end of the connecting pipe 3 is sealed and connected with the orifice end of the grouting drilling channel 2, and the other end is connected with the grouti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com