A kind of deep gently inclined thin ore vein continuous mining method without ore pillar

A mining method and gently inclined technology, which is applied in the new mining field of continuous mining with gently inclined thin veins and no ore pillars, can solve the problems of operation hazards, threats to the safety of operators, and reduce the climbing angle of rock drilling rigs, so as to improve safety The effect of improving operating conditions, improving operating safety conditions, and reducing the workload of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

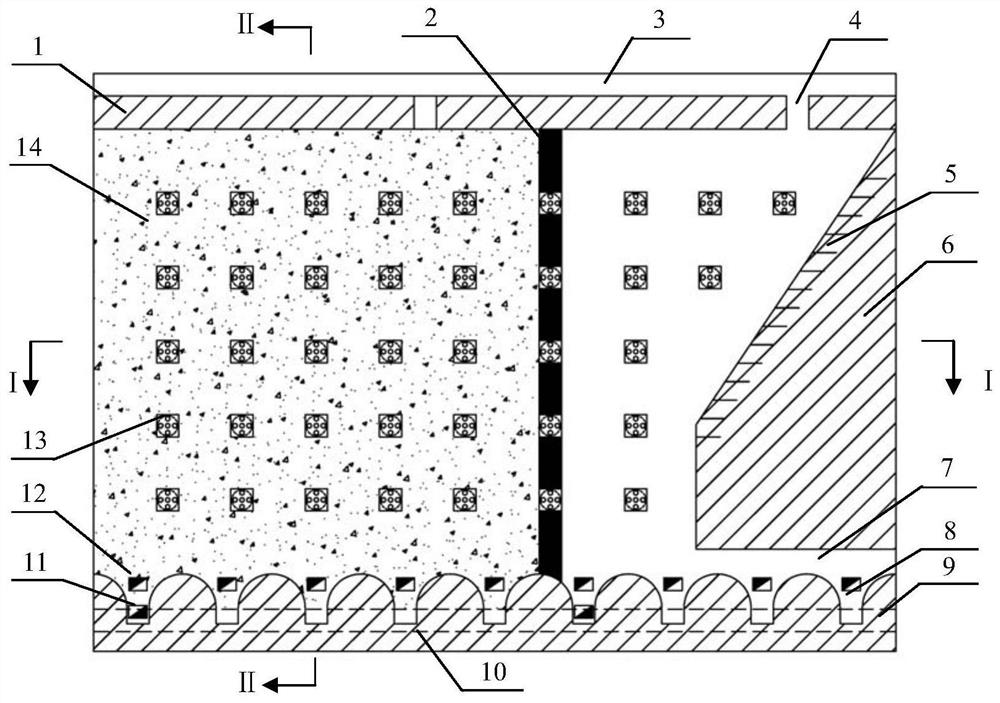

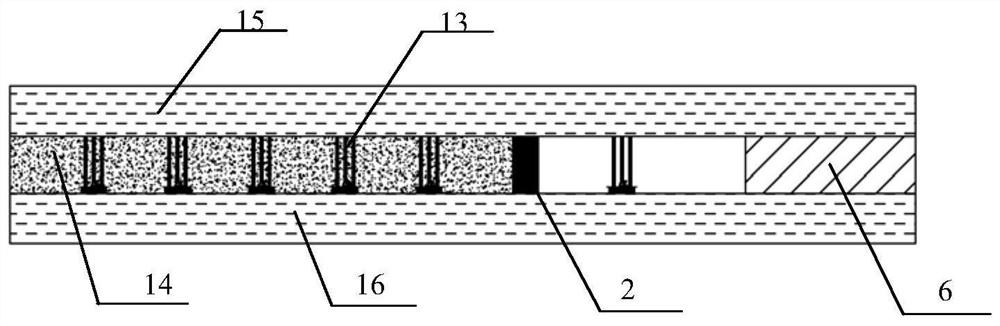

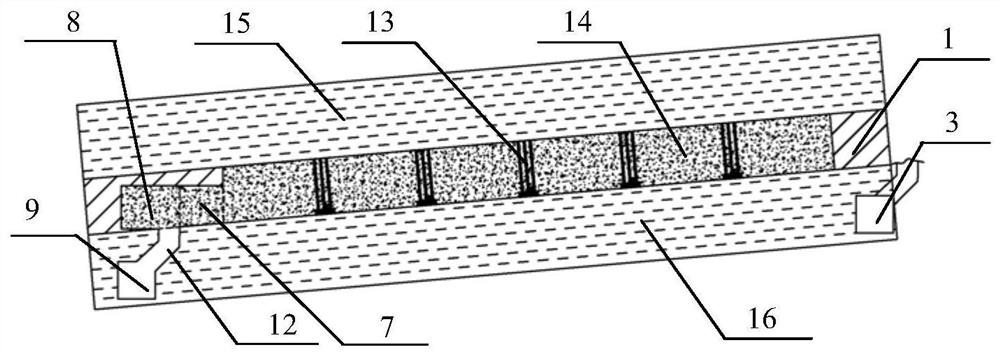

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] combine Figure 1 to Figure 4 , the deep gently inclined thin vein of the present invention has no ore pillar continuous mining method, comprises the following steps:

[0030] 1. Stope layout: within the stage, along the direction of the ore body, every 40m is divided into a partitioned strip, and the mine room and the inter-column are no longer divided, and the partitioned strip is used as the mining unit for continuous mining from one side to the other. A bottom column 10 of 3-5 m is left at the bottom, which is also the top column 1 to be mined in the next stage.

[0031] 2. Mining and cutting: Transport the entryway 9 during the excavation stage outside the ore body lower vein, and excavate the pedestrian ventilation patio 11 every 40m along the stage to the stope for pedestrian ventilation; transport the entryway along the stage 9 Excavate the ore chute 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com