Large-swing-angle stepless self-moving type simple hydraulic roof bolter used in cooperation with open-type TBM

A large swing angle, open technology, applied in the field of TBM, can solve the problems of low support efficiency, failure to support, large volume of hydraulic bolter for support, etc., to improve strength and stability, and improve support coverage Effect of simplification of range and movement system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

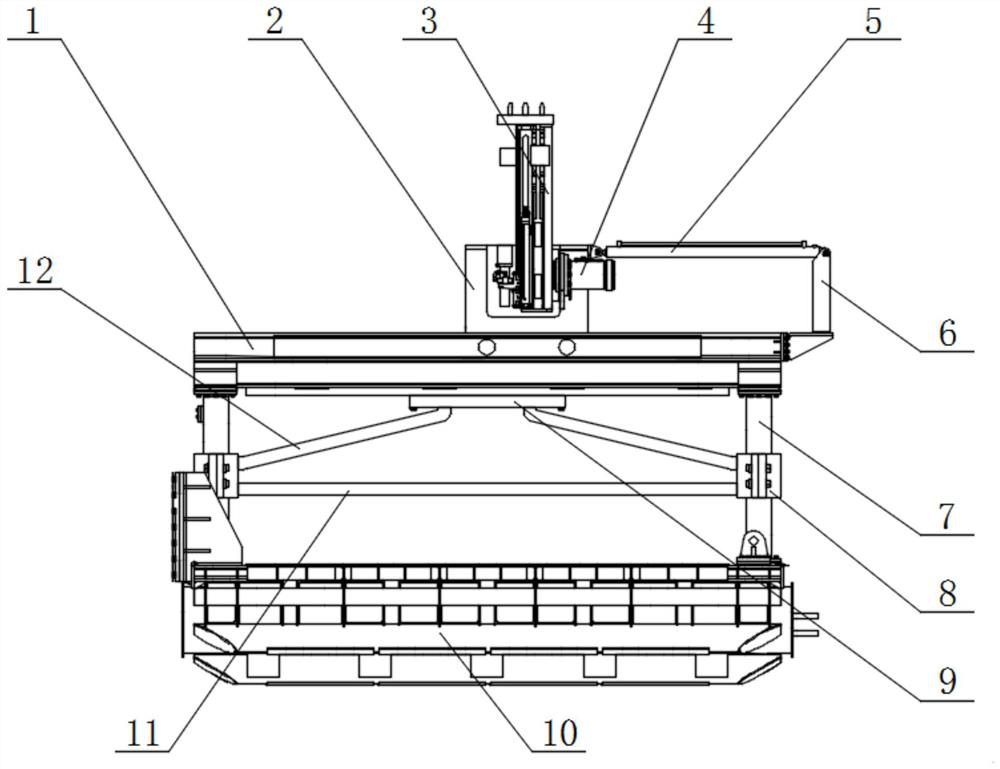

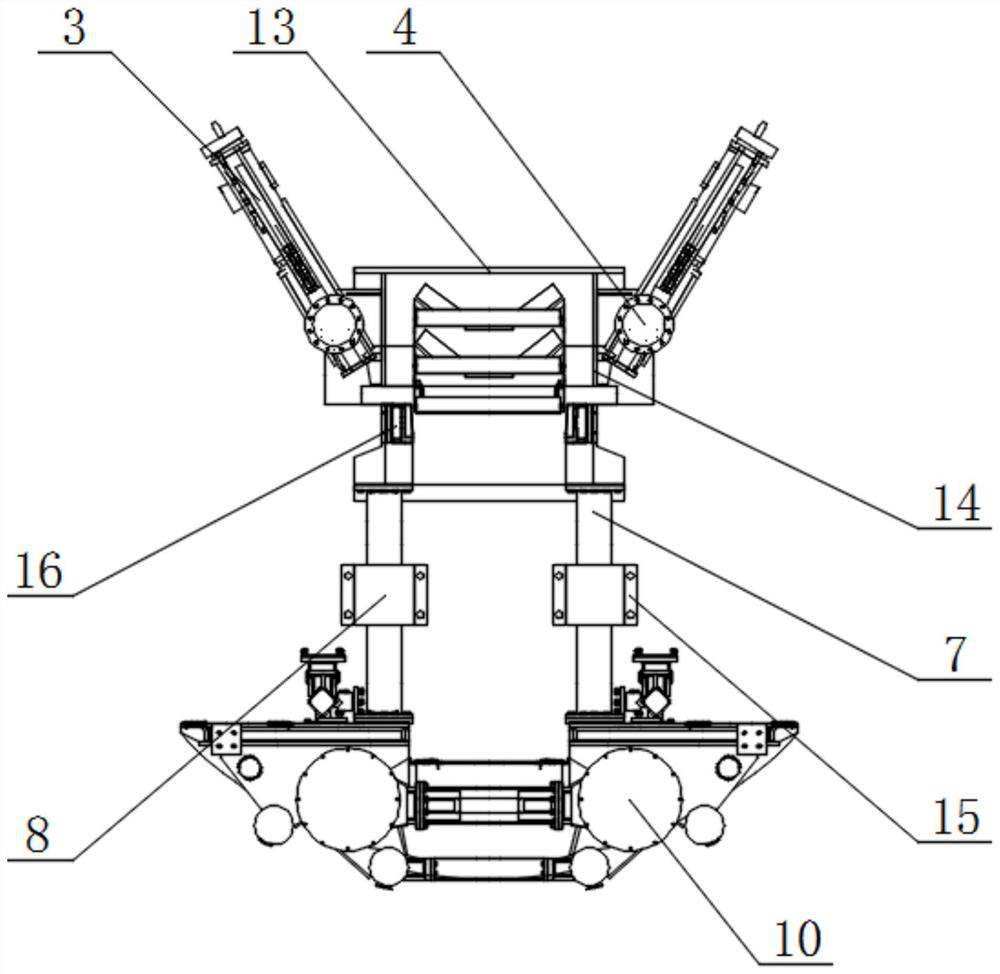

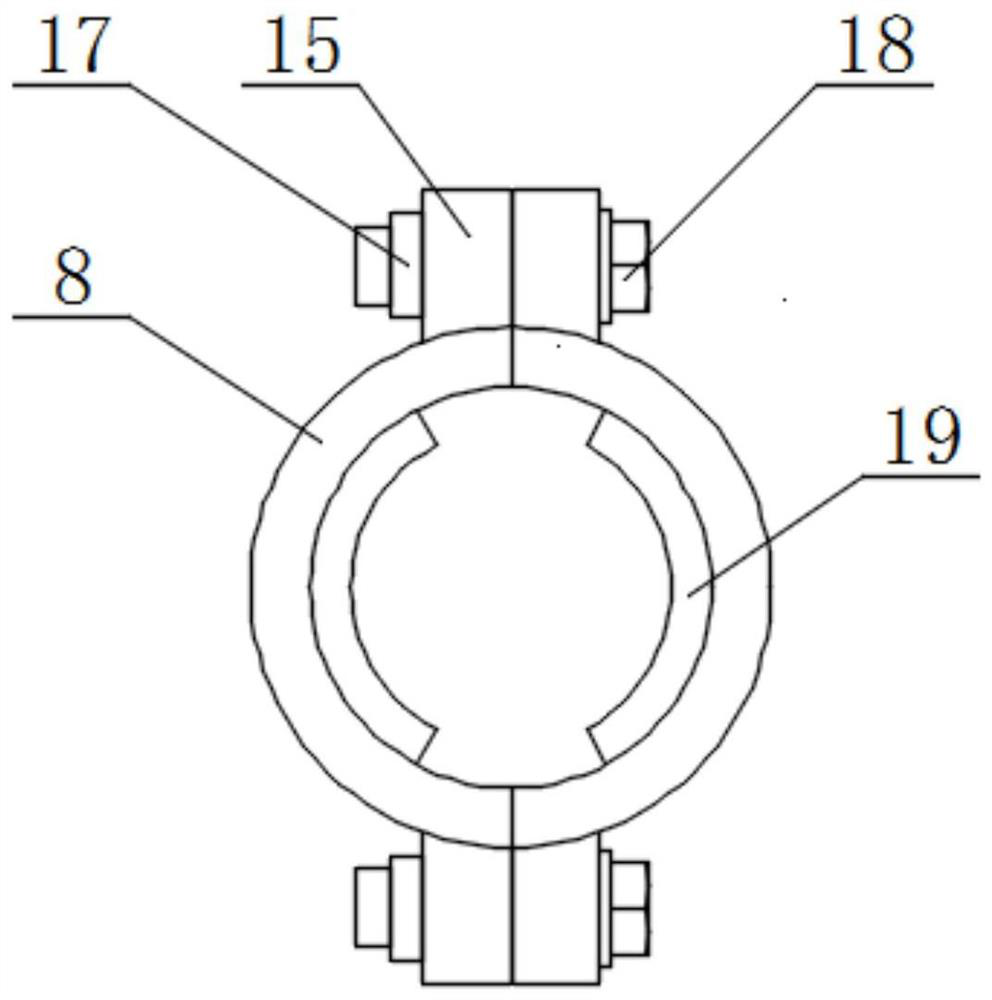

[0026] see Figure 1-6 , the present invention provides a technical solution:

[0027] A large-swing angle stepless self-moving simple hydraulic bolter for an open TBM, including a body 1, an installation base 2 and a roadheader 10. The four corners on the upper side of the roadheader 10 are provided with support rods 7, and the support rods 7 pass through The screw is connected with the roadheader 10, the support rod 7 is arranged on the bottom side of the body 1, the support rod 7 is connected with the body 1 through screws, the upper side of the body 1 is connected with a support frame 6, and the support frame 6 is connected with a horizontal propulsion cylinder 5, and the horizontal The propulsion cylinder 5 is connected to one side of the installation base 2, and the installation base 2 is slidingly connected to the upper surface of the body 1. The front and rear sides of the installation base 2 are provided with a simple hydraulic drilling rig main body 3, and the simple...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap