Dust barrel capable of carrying out full dust detection in real time, dust collector and full dust detection method

A dust bucket and buzzer technology, which is applied in the installation of vacuum cleaners, electrical equipment, household appliances, etc., can solve problems that affect the working efficiency of vacuum cleaners, secondary pollution, and dust buckets that cannot be real-time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

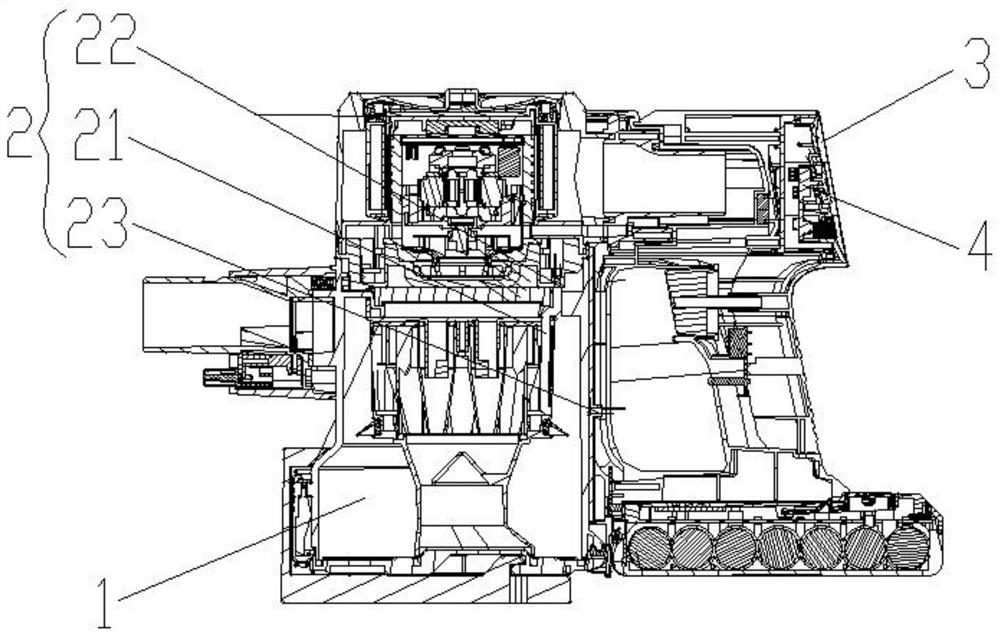

[0024] Embodiment 1 discloses a dust bucket that can detect full dust in real time, such as figure 1 As shown, it includes a dust bucket 1, and also includes a light sensor 2 and a prompt module 3. Specifically, the light sensor 2 is an infrared sensor. The two ends of 21 correspond to the light emitting end 22 and the light receiving end 23. The light transmission channel 21 is a tube body made of thermoplastic polyurethane elastomer material. The inner bending part of the tube body is provided with a reflective film. The light transmission channel 21 The bottom end of the dust bucket 1 is horizontally aligned with the top position of the side wall of the dust bucket 1 and there is a gap between the side wall of the dust bucket 1. The prompt module 3 is arranged outside the dust bucket 1. Specifically, the prompt module 3 is fixedly arranged on the side wall of the vacuum cleaner. On the outer wall of the casing, the light transmitting end 22 and the prompting module 3 are po...

Embodiment 2

[0034]Embodiment 2 discloses a dust bucket that can detect full dust in real time. This embodiment is the same as other structures in Embodiment 1. The difference is that the optical sensor 2 is a laser sensor, and the prompt module 3 is directly fixed on the dust bucket 1. On the outer wall of the outer wall, the light transmission channel 21 is fixedly arranged on the side of the filter end in the inner cavity of the dust bucket 1, and the light emitting end 22 is set correspondingly to the bottom end of the light transmission channel 21, and the light emitting end 22 is fixed on the side of the dust bucket 1 On the wall, the position where the light emitting end 22 is set on the side wall of the dust bucket 1 is connected with the inner cavity of the dust bucket 1, and the light receiving end 23 is set corresponding to the top position of the light transmission channel 21 and the light receiving end 23 is fixedly arranged on the dust bucket 1. On the top wall of the bucket 1...

Embodiment 3

[0036] Embodiment 3 discloses a dust bucket that can detect full dust in real time, including a dust bucket 1, a light sensor 2 and a prompt module 3, specifically, the light sensor 2 is a photoresistive sensor, and the light sensor 2 includes a The light transmission channel 21 on the top of the cavity of the bucket 1 and the light emitting end 22 and the light receiving end 23 are arranged corresponding to the two ends of the light transmission channel 21. The light transmission channel 21 is a tube body made of thermoplastic polyurethane elastomer material. The inner bending part of the body is provided with a reflective film, the bottom end of the light transmission channel 21 is horizontally aligned with the top position of the side wall of the dust bucket 1 and there is a gap between the side wall of the dust bucket 1, and the prompt module 3 is arranged on the dust bucket 1, specifically, the prompting module 3 is fixedly arranged on the outer wall of the vacuum cleaner,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com