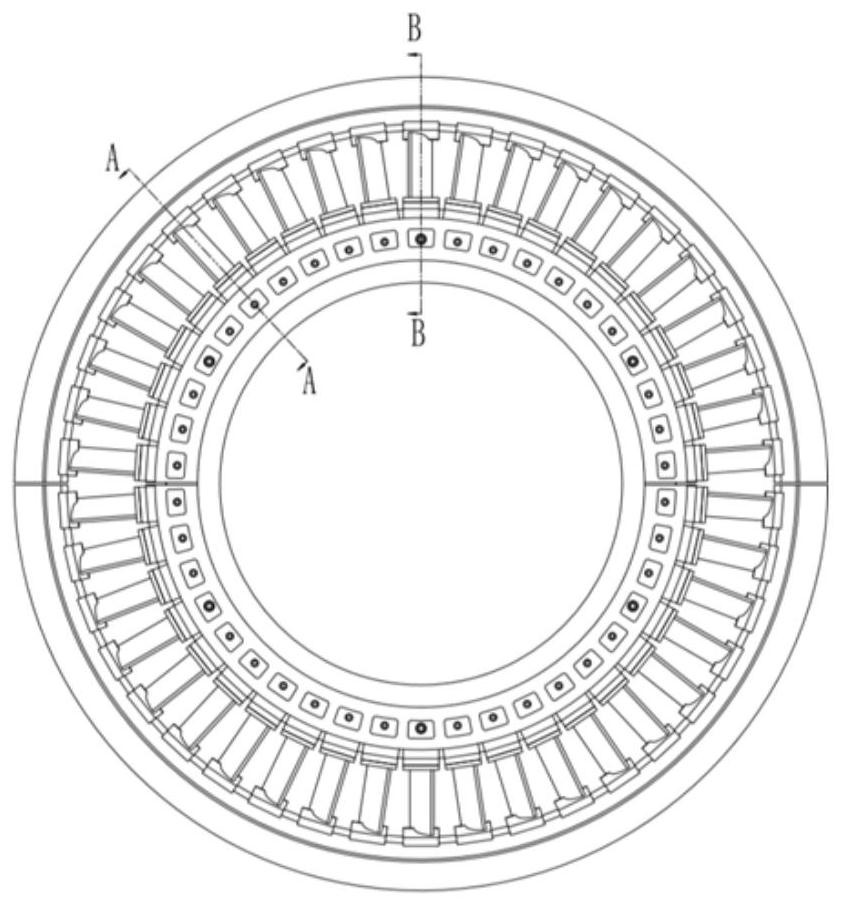

Turbine first-stage stationary blade supporting device

A technology of support device and stator, applied in the direction of machine/engine, stator, mechanical equipment, etc., can solve the problem of cumbersome installation process, achieve the effect of improving installation efficiency and reducing the time for axial adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

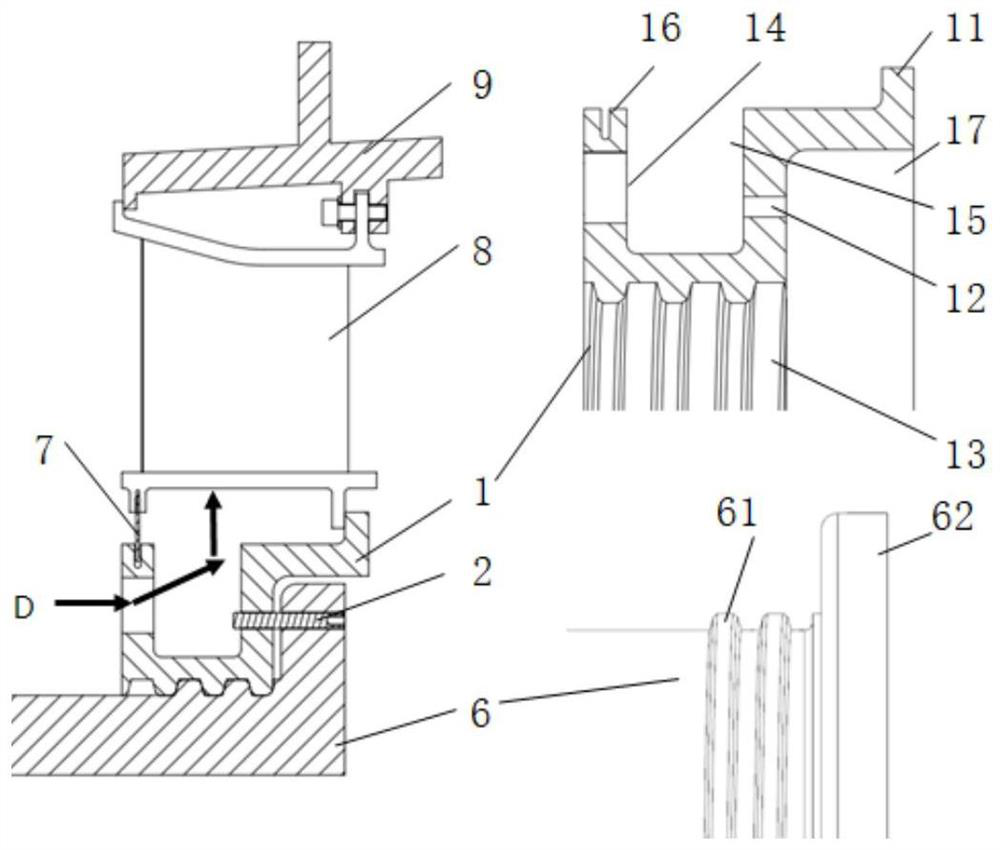

Embodiment 1

[0055] In Embodiment 1, the first support ring 1 and the first rotor shroud 6 adopt threaded contact instead of the way that the first support ring 1 and the first rotor shroud 6 are completely axially fixed, so that the first rotor shroud 6 does not need The position adjustment process of the first support ring 1 of the stator blade 8 can be realized by moving, which greatly simplifies the installation and positioning process. Moreover, the threaded contact scheme of this embodiment increases the axial position adjustment ability of the first support ring 1 itself, and its position movement depends on the contact rotation of the thread surface, and does not rely on the scheme of grinding the excess of the support ring, and does not require secondary machining. The machining process is simplified, and the rapid adjustment of the axial position of the first support ring 1 is realized.

Embodiment 2

[0056] Embodiment 2 On the basis of Embodiment 1, the adjustment method of the support ring is changed, and the support ring moves linearly relative to the rotor shield to adjust the axial displacement, and the axial quick adjustment of the support device of the stator blade 8 is also realized. The support ring in the second embodiment is the second support ring 20 , and the rotor shield is the second rotor shield 64 .

[0057] Such as Figure 8-Figure 11 As shown, the support device includes the second support ring 20 , the top screw bolt 10 , the first fixing bolt 18 , the second fixing bolt 19 and the second rotor shroud 64 . Figure 10 It shows a plurality of waist-shaped holes arranged in the circumferential direction of the second support ring 20 , and the long side direction of the waist-shaped holes is consistent with the axial direction of the second support ring 20 . The second support ring 20 adjusts the axial displacement of the second support ring 20 relative to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap